sheet metal full process Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes. $19.99

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal working process pdf

4 · sheet metal process pdf

5 · sheet metal process in manufacturing

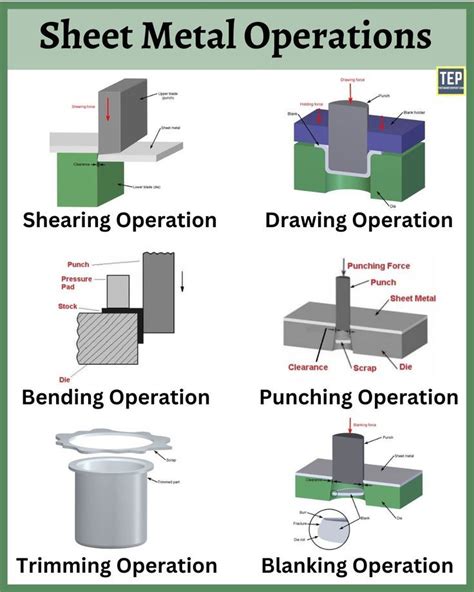

6 · sheet metal operations with diagrams

7 · sheet metal fabrication pdf

Discover the key concepts, formulas, and techniques used by experienced engineers to precisely unfold complex geometries. Learn how to apply these principles to your own designs and streamline your manufacturing process. The first step in the sheet metal fabrication process is the unfoldment of the geometries and the coherent body.

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly .Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes.

The precision sheet metal fabrication process involves producing precise sheet metal components for vehicles. The process begins with design, followed by cutting, forming, joining, finishing, quality control, and packing. This white paper explores the key components of sheet metal fabrication, ranging from the processes to materials, finishes, design tips, and more.

In the sheet metal fabrication process, the CNC Turret Punch Press process uses a turret that will quickly change tools to cut the desired shape, while typically, the table is programmed to move to accept the punch tool. The CNC punch tool . 5. Sheet Metal Processing The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. If the sheets are .and full hard 0.075. Factors affecting shearing operation • Shape and material of the punch • Die, speed of punching, lubrication . a metalworking process where sheet metal is pressed between a die and a rubber block, made of polyurethane. Under pressure, the rubber and sheet metalDuring process engineering, in order to gain greater insight into the stamping process, engineers must carry out the simulation of drawing and secondary operations, such as restriking, trimming and flanging as well as springback. Our state-of-the-art software enables the rapid and accurate simulation of all operations of the stamping process.

Sheet Metal Stamping is a low-cost high-speed manufacturing process that produces a high volume of identical metal components, which has contributed importan.

Updated 16 August 2023. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods.The completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling.

This sheet metal forming process is often used for vehicle body parts, enclosures, and electrical components. It can be performed on most compatible sheet metal forming materials, like stainless steel, brass, aluminum, and galvanized steel. It does have some limitations, however; the metal needs to have the same thickness throughout, and . Hemming is a sheet metal forming process in which sheets are joined by bending it to 180°. Automotive body panels and automotive parts such as deck-lids, trunk-lids, doors, hoods and tailgates are formed by hemming process. In this process, usually a sheet is bent with the help of inner sheet in three different stages.Welcome to contact with us if you have sheet metal parts want to custom make:Email: [email protected]: +86 13727008794#SheetMetalStamping#MetalStampi. In this process, the sheet metal is worked into a drawn cup by the deep drawing process and then deformed to the target shape by compressing the cup edge. . [Show full abstract] sheet is .

Sheet Metal Embossing Process Animation in SolidworksEmbossing:It is a Metal Forming Process for Producing raised or sunken designs in sheet metal material b.Good sheet metal design goes beyond basic guidelines and considers the type of sheet metal fabrication process, material, finish, fastening, and tailors all these factors to the specific function. Here are some useful resources on sheet metal fabrication, as well as other resources related manufacturing if you want to delve deeper.Principles of Incremental Sheet Forming Incremental Sheet Forming is a versatile manufacturing process that involves the gradual deformation of a metal sheet using a localized tool. Unlike traditional forming processes that utilize dies and molds, ISF employs a CNC-controlled tool that moves incrementally, shaping the metal sheet layer by layer. A stamping press machine is a machine that can process sheet metal into the desired shape. It is commonly used for metal stamping to convert a flat metal sheet into a specific shape. . Starbuck (2011) Full Movie Watch Online Review: Like a Dragon: Infinite Wealth - Oneindige fun. Was Single Long A True Story Dreamworld De Que Trata Sam .

The sheet metal blanking process is a fundamental aspect of the manufacturing industry that converts flat metal sheets into specific, predefined shapes for a variety of uses. This method is known for its efficiency and is especially advantageous for high-volume production. Let’s take a closer look at how sheet metal blanking operates. Bending is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. 7. Two common bending methods are: V-Bending Edge bending V-Bending: .Sheets of Nirosta stainless steel cover the Chrysler Building. Microscopic close-up of mild steel sheet metal. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.. Thicknesses can vary significantly; extremely .

Today we're going to show the full process of louvering the sheet metal panels for under the hood on the 1955 Mercury 🔥IF YOU ENJOYED WATCHING:subscribe, le. Metal forming [1] is a manufacturing process that is used to reshape metal into the desired shape by applying forces to it. This process is known as plastic deformation, as the metal undergoes . Get full access to this article. View all access and purchase options for this article. . Senn M, Jöchen K, Van TP, et al. In-depth online monitoring of the sheet metal process state derived from multi-scale simulations. Int J Adv Manuf Technol 2013; 68: 2625–2636. Crossref. Google Scholar. 15. Van TP, Jöchen K, Böhlke T. Simulation of .

Progressive die stamping is a metal forming process widely used to produce parts for various industries, such as automotive, electronics and appliances. Progressive die stamping consists of several individual work stations, each of which performs one . Sheet metal extrusion is a process in which the extrusion punch penetrates one surface of the sheet metal material to cause it to extrude and flow toward the outlet of the die. In fact, this process is a combined process in which both extrusion and penetration occur at the same time. . Download : Download full-size image; Fig. 1. Sheet metal .

various sheet metal processes

types of sheet metal process

Fig. 2 Radial riveting equipment and riveting process. Process selection and precautions of riveting (1) The size of the riveting bottom hole should be designed in strict accordance with the manuals of general or special equipment, standard parts, and should comprehensively consider the material, thickness, model, and strength requirements of the .

See full PDF download Download PDF. Related papers. Sheet metal operation. Arpan Chaudhari. . Edge Bending (wiping) Edge bending is another very common sheet metal process and is performed with a wiping die. Edge bending gives a good mechanical advantage when forming a bend. However, angles greater than 90 degrees will require more complex . Download : Download full-size image; Fig. 1. Temperature dependent flow curves of AZ31B (s 0 =1.0 mm) . The heating of the blank represents an additional process stage in sheet metal forming of magnesium alloys compared to the conventional sheet metal forming at room temperature.

types of sheet metal fabrication

However, like any other process, sheet metal fabrication is accompanied by significant safety risks. In 2022, the incidence rate of nonfatal occupational injuries and illnesses in this industry was approximately 4.3 per 100 full-time workers, notably higher than the average for all private industries. Common injuries in sheet metal fabrication .

sheet metal working process pdf

The precision sheet metal fabrication process is ideal for high-quality manufacturing due to the various benefits it offers. For example: Customization: This process allows manufacturers to produce parts and components tailored to meet precise requirements. They just need to modify factors like shape and size to produce custom solutions for .

sheet metal process pdf

Then use the Spring Nuts that you can purchase with the strut to attach the boxes, and Strut Straps to support a bit of EMT conduit that you stubb up. Sleeve the romex inside the EMT. You should also purchase edge guards for the ends of your unistrut.

sheet metal full process|sheet metal process in manufacturing