solidworks simple sheet metal part By the end of this tutorial, you'll be well-equipped to design your own sheet metal components confidently in SolidWorks. Music: Inspire by Wavecont https://protunes.net Video Link: •. Whether you’re a MIG welder, a TIG welder, or want a machine you can do both with, we have reviewed a range of different welders to help you narrow down a good choice for your next project. 1. Miller Electric 211 – Best MIG Welder.

0 · solidworks sheet metal pdf

1 · solidworks sheet metal examples

2 · solidworks sheet metal drawing pdf

3 · solidworks sheet metal download

4 · solidworks sheet metal basics

5 · sheet metal modeling in solidworks

6 · sheet metal in solidworks 2021

7 · sheet metal 3d sketch solidworks

1) You could remove the existing conduit and add another junction box below the panel, then run conduit(s) from the panel into the new junction box. Then run the existing conduit into the bottom of the box, re-pull the wire and splice the existing circuit.

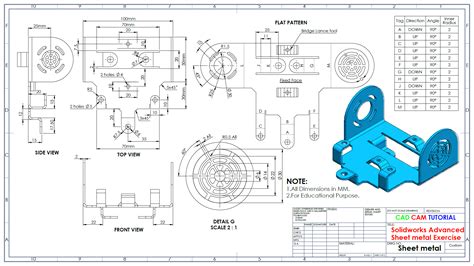

SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create . In this lesson, you create the sheet metal part. This lesson demonstrates: 1.Creating a base flange 2.Adding a miter flange 3.Mirroring the part and creating. By the end of this tutorial, you'll be well-equipped to design your own sheet metal components confidently in SolidWorks. Music: Inspire by Wavecont https://protunes.net Video Link: •.Sheet Metal Properties. Properties specific to sheet metal parts are calculated and displayed in the Cut-List Properties dialog box. Linking Materials and Sheet Metal Parameters. When you .

The Sheetmetal part is symmetric with respect to the right plane except for the last two edge flanges. Sheetmetal features are used so that the part can be flattened out to create a flat . Simple Sheet Metal Part 4: Start off with flat plate and then add edge flanges. Sheetmetal features are used so that the part can be flattened out to create a flat pattern. Modified sketch to include large rectangular cutout .This is part two in a six part series. Take a look back at the Simple Sheet Metal Part 1. Download: simple sheet metal part 2 Complexity: Basic Features used: Base Flange, Edge Flange, Hem, . There are multiple methods for making sheet metal parts in Solidworks using the Sheet Metal tab. In this article, we will look at using the Sketched Bend feature and also the Edge Flange feature. Both of these .

Check out Part 1, Part 2, Part 3, Part 4, Part 5, Part 6, Part 7, and Part 8 of the Simple Sheet Metal Part Reviewer tutorial series to learn more! Download: Simple Sheet Metal Part 9 . The Sheetmetal part is symmetric with respect to the right plane except for the last two edge flanges. Sheetmetal features are used so that the part can be flattened out to create a flat pattern. Download the part below to .simple sheet metal part. DS By Dave Stevens 10/27/10. Can someone step me thru createing this as a sheetmetal part? Never used sheetmetal before. answers: 18. View or Reply . Use your 3DEXPERIENCE ID to log in. . ©2002-2024 Dassault Systemes SolidWorks Corporation .

The lines will be thickened and all the sharp edges will be turn into bends. Sheetmetal features are used so that the part can be flattened out to create a flat pattern. Check out Part 1, Part 2, Part 3, Part 4, Part 5, Part 6, .Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal . Simple Sheet Metal Part 8: This is a sheet metal part symmetric with respect to the Front Plane with the exception of a few cutouts. Sheet metal features. . Dassault Systèmes SolidWorks Corp. offers complete 3D software tools that let you create, simulate, publish, and manage your data. SolidWorks products are easy to learn and use, and work .

Simple Sheet Metal Part 5: This Sheet Metal part is symmetric vertically with respect to the Right Plane.Sheetmetal features are used so that the part can be flattened out to create a flat pattern. Base Flange/Tab feature can be used not only as the first feature on the model, but can be used to add more material at the same thickness as rest of part.Why is Solidworks so difficult on its features. draw a simple sheet metal part with 2 bends..created a plane 5 inches from it so the the mirror is 10 inches..then try to mirror and it just wont do it.. Im trying to be a believer in solidworks, but Autocad is still way simpler. I drew this same part and mirror it in 30 seconds in Autocad. There are multiple methods for making sheet metal parts in Solidworks using the Sheet Metal tab. In this article, we will look at using the Sketched Bend feature and also the Edge Flange feature. Both of these features are used to create bends starting from a flat piece of metal. . Making holes in sheet metal is simple. It’s the same as . All sharp edges will be converted into bends once it is extruded. Check out part 1, part 2, part 3, part 4, part 5, and part 6 of the Simple Sheet Metal Part Reviewer tutorial series to learn more! Download: Simple Sheet Metal Part 7 Complexity: Basic Features: Cut Extrude, Sheetmetal, Flange, Mirror. View all the Part Reviewer Tutorials here.

solidworks sheet metal pdf

Simple Sheet Metal Part 6: This sheet metal part is symmetric with respect to the Right and Front Plane. Extruded one half the model and will then mirror. . Dassault Systèmes SolidWorks Corp. offers complete 3D software tools that let you create, simulate, publish, and manage your data. SolidWorks products are easy to learn and use, and work .Sheet Metal SOLIDWORKS® Standard Last Update: December 2021 . When designing sheet metal parts, the order preference for use of feature tools are as follows: . This is because the Normal Cut option is not available for the Simple Hole feature and the Hole Wizard feature. The next image (Figure 5) depicts a cut-extrude without the normal .Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .When you mirror features and bodies in a sheet metal part, many of the bends are mirrored as well. The only bends that are not mirrored are those that are normal to and coincident to the mirror plane; those bends are extended. . Search 'Mirroring Sheet Metal Parts' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic. SOLIDWORKS .

Flattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Completing the Sheet Metal Drawing. Next, add a view of the unfolded model.

If creating a sheet metal part with one or more conical faces, you must select K-Factor as the type of bend allowance. If you selected K-Factor, Bend Allowance, . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this .

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .The sheet metal-specific features make it easier and faster to create a sheet metal part than designing a part, then converting it to sheet metal. SOLIDWORKS includes sheet metal-specific features so you can create a part as sheet metal without having to convert it to sheet metal.

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .Let's zoom in on one of the sheet metal parts and flatten it. A bend notch is the next feature this part needs. This new tool will add marks to make it easy for the operator to line the bend lines up in a press break or other subsequent manufacturing operations. . In SOLIDWORKS 2025, it just takes a simple checkbox to get a flag in the .

Hopefully mine will be simple. At the moment on a sheet metal part to get it to a flat pattern .dxf file I - right click the "flat-pattern" feature "export to DXF / DWG" on the drop down bar Save as In the same file location as the part itself I change the name to "File name - Flat-Pattern" Save under the DXF / DWG Output I select, Sheet metal .

Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .

I have a simple sheet metal part that when I make into flat pattern makes it absurdly larger than the bent part. Anyone know a fix? Fig 1. Bent pattern Fig 2. . ©2002-2024 Dassault Systemes SolidWorks Corporation .Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .You can create a multibody sheet metal part from multiple sheet metal bodies or a combination of sheet metal bodies and and other bodies such as weldments. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic .

The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Any idea why this part won't let me flatten? . Sheet metal won't flatten - simple part. VV By Valery Volkov 07/17/20. Any idea why this part won't let me flatten? Uploaded part (SW 2019 + STEP) -Val. answers: 14. View or Reply .If you use the sheet metal tools in Solidworks (or most other CAD software), some of the cuts and notches are generated kind of automatically when you bend a side, etc. . There were loads of simple sheet metal parts all over the machine, covering this and that. Our supplier has already been working with us for decades at that point, so all we .

Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. In the PropertyManager, under Sheet Metal Parameters, select the fixed face. Under Bend Edges, click Collect All Bends. I do not do much with sheet metal, mostly simple parts. However, I believe one way to make a dimple is with a forming tool. Look under SolidWorks help for more info. . new or same folder. Then Edit the Defintion of the Feature. You can find the feature Palette under the C:\Program Files\Solidworks\Directory\Data Regards, Scott Baugh, CSWP .

cnc laser cutting tube machine supplier

solidworks sheet metal examples

Junction boxes like that one are 8-32. Ground screws are 10-32. Also, you could buy a ceiling hugger style fan instead of a stem mounted one, and fasten it directly to the ceiling with toggle bolts or similar fasteners, instead of just .

solidworks simple sheet metal part|solidworks sheet metal basics