steel box girder design crane A box girder crane uses two webs and a top and bottom flange that create a box shape. Despite the difference in the shape of the bridge, a box girder crane still uses end trucks with an adapted design to connect it with the bridge . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

0 · overhead crane girder design

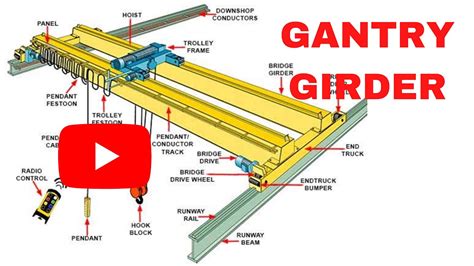

1 · gantry wheel girder design

2 · gantry crane girder dimensions

3 · gantry crane girder design

4 · gantry crane girder beam web

5 · crane girder equation

6 · crane girder design guide

7 · box girder for crane

Simply install the junction box, and pass the wires through the side of the box. There are openings on both sides for the entry and exit of wires. How to Calculate the Number of Wires in an Electrical Box? Stuffing in too many wires within a single junction box may lead to dangerous outcomes.

CRANE GIRDER DESIGN. Crane girders are distinguished by long unbraced lengths and combined bending about the x and y axis as well as torsion. For typical loading and spans, a . Designing a box girder for a crane is a complex process that involves several steps and considerations. KTM Engineering has been designing box girders for well over a decade with more than a hundred designs in use .Therefore, the purpose of this paper is to present information relative to the design criteria in addition to information on pre liminary plate sizes, design aids, and computer-aided design of .Crane Girder Design This work discusses the issues structural engineers must address when considering the requirements of the current American Institute of Steel Construction steel .

A box girder crane uses two webs and a top and bottom flange that create a box shape. Despite the difference in the shape of the bridge, a box girder crane still uses end trucks with an adapted design to connect it with the bridge .

this paper is to optimize design and analyze the 550 ton of capacity Gantry crane with welded box section of Girder. The design optimization is made by altering the dimensions of gantry crane .This Guidance Note gives an overview of the main design issues for steel box girders in short and medium span bridge schemes. SCI- publication P140 (Ref 1) gives a more exten- sive .

Lateral-torsional buckling. Gantry girders are unrestrained, and have lateral loads applied at the top flange level (or above). As the beam buckles, the vertical loads may be eccentric to the .examples of crane girder design to the Eurocodes. David Brown of the SCI rises to . Full range of advanced steel sections available ex-stock angularity, but for a quick check, assume that C 1 = 1.13, mainly for easy use of the look-up tables in the Blue Book. For the trial section of a 533 × 210 × 101 UB in S275 (note

overhead crane girder design

Cons of Box Girder Bridge Cranes. While box girder bridge cranes have many benefits, they are not without their drawbacks. Some of the cons include: 1. Higher Initial Costs. Due to their complex design and the materials used in construction, box girder cranes tend to be more expensive upfront compared to single girder or I-beam cranes.CRANE GIRDER Crane Girder is an assembly of steel plates, angle and rails. Steel plates forms the flange and web of girder while the angle forms the stiffening part of the web plate. Steel plates are also used as diaphragms of the girder. Together all of these make up a box section. The girder box section is shown below: Figure-2 Crane Girderimportant to develop suitable design procedures and aids. Due to the variables involved in the design of wide flange and channel combination sections under bi-axial bending and torsion, new design tables and design aids will prove espe cially valuable. CRANE GIRDER DESIGN Crane girders are distinguished by long unbraced lengths and

elements, design criteria had to be established. Therefore, the purpose of this paper is to present information relative to the design criteria in addition to information on pre liminary plate sizes, design aids, and computer-aided design of steel box girder bridges. INTRODUCTION Box girders have become a prominent element in the con

design of steel structures. The new specification unified the design standards with the most current knowledge and design practices that focus on strength rather than on stress. One notable change is that the term “Allowable Stress Design” in the 9th edition has been officially changed to “Allowable Strength Design.” For crane runway .

Structural Design . Designing a crane girder according to BS5950 involves numerous steps to ensure that it can safely support the applied loads, including the weight of the crane and the lifted load, the crane movement, and the imposed wind loads. . In the context of BS5950, which is a British Standard for the design of steel structures, the .The Objective of This Guide. The analysis and design of the crane moving load calculate the influence of the vertical and horizontal loads (Max./Min. node displacement, Max./Min. member strength, and reaction) caused by moving the crane on the crane girder, and it means a series of analyses and design processes for designing crane girder under common structures. Design of Underhung Hoist and Crane Girders. Underhung crane girders are often used in manufacturing, industrial, and power plants and have particular design challenges including member continuity, laterally unsupported flanges, fatigue of . Crane Girder design is an Excel Spreadsheet Template for the design of simply supported crane girders. The procedure is based on the Steelwork Design Guide to BS 5950-1:2000, Volume 2, Worked Examples, SCI Publication P326, .

The existing structure using SS400 steel plates is evaluated and compared with a new design using ST52-3. . structure of the box-type girder of an overhead crane . . steel plate girder railway . There are two main styles of box beams for double girder cranes: Standard or American box beam; This type of beam has the trolley rail located in the top center of the box and allows a beam design with the most economical use of steel to fabricate the girder. Torsional box beam; This beam uses the trolley rail located above the inside web of .Mass optimization of crane box girder considering both ribs and diaphragms is a crucial aspect of crane structural design in mechanical engineering. However, two common challenges often obscure this process: the sizing of stieners such as . crane steel box girder considering the iteration of dimen-sion, number and location of stieners such as . Mass optimization of crane box girder considering both ribs and diaphragms is a crucial aspect of crane structural design in mechanical engineering. However, two common challenges often obscure this process: the sizing of stiffeners such as diaphragms and ribs, and the selection of constraints on state variables related to stresses and deformations for various .

Higher Load Capacities:Double girder gantry cranes can lift weights ranging from 10 to 50 tons or more, making them suitable for heavy-duty tasks in manufacturing and construction.The robust design allows these cranes to tackle large machinery, steel plates, and heavy components, ensuring they meet the demands of diverse operations.are provided for design checks at particular girder locations, a bolted field splice design, an internal pier diaphragm design, and a top flange lateral bracing member design. 17. Key Words 18. Distribution Statement Steel Tub Girder Bridge, Steel Box Girder Bridge, LRFD, No restrictions. This document is available to the public through Girders can be made of rolled steel or can be fabricated by welding the beams into a steel box design for added strength and rigidity. The bridge is a load-bearing beam that runs the width of the crane bay and is the primary .Manufacturer Of Eot Cranes, Cranes, Single Girder EOT Crane, Double Girder EOT Crane, Barrel Winch Cranes, Electric Overhead Travelling Crane, Mumbai, India (022) 27791181 / 27790344 [email protected]

Box Girder Bridge Crane Applications; Contact Info. 8000 Joliet Rd., Building 1 Mc Cook, IL 60525; . The structural design of a single-girder crane also allows for the creation of a freestanding workstation bridge crane system. This setup gains exceptional rigidity from the secure connections between columns and headers, as well as between .

complete design of crane run ways. Many sources o-f information apply to steel structures in general and do not address some of the more important design and practical aspects of crane runways. It is the purpose of this report to review the various standard procedures

2 REASONABLE DESIGN METHOD OF CRANE MAIN GIRDER 2.1 Calculation model and effective load Crane box girders are subjected to many load components in different working states and conditions. Fig.2 is the calculation diagram of the crane girder steel structure. Loads include the self-weight of the crane girder structure, The subject of the research presented in this article is the dimensional optimisation of the box structure of the main girder for overhead cranes, with the aim to reduce the main girder’s own weight. Described are the applied optimisation methods and also the problems arising during the optimisation process. Loss of shape stability is analysed in more detail, as .Photocopy in Cranes Box 621.873 Author LAMAN JEFFREY Publish Date 30 Nov 1996 Media Type Journal article Call Number . AASHTO LRFD provisions for the seismic design of steel plate girder bridges

Box girder bridges No. 1.08 SCI P185 Guidance notes on best practice in steel bridge construction 1.08/1 GN107R3.doc Revision 2 Scope This Guidance Note gives an overview of the main design issues for steel box girders in short and medium span bridge schemes. SCI-publication P140 (Ref 1) gives a more exten-sive treatment of steel box girder design.The design of an overhead crane with a double box girder has been investigated and a study of a crane with 10 ton capacity and 12 m span length has been conducted. It is not possible for the real experimental studies to take into consideration the influence of the connections between the main beams and the rest parts of the construction, the .

Crane main girders are categorised as truss girders, box girders, single girders, and double girders, and many other types of structures. Single girder, double girder, triple girder, box girder, truss grider, and other girder designs are available. Please do not hesitate to contact us if you require crane girder design.“Design Optimization of Box Girder in Gantry Crane using Finite Element Analysis Software” (Harshil Patel, Dhruv Upadhyay, Divyang Patel), In this paper, there is a comparison shown between the results from existing design and the results from optimized design using finite element analysis of solid model girder. 8.

cardboard boxes metal gear survive

captian america lunch box metal

A sharp bend occurs when the bend radius used is too small for the type of material you’re bending. Because the bend radius relies on the punch . See more

steel box girder design crane|overhead crane girder design