how to set up cnc machine In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to the first cut. The first step in setting up a CNC milling machine is to inspect the . In this article, we will explore the factors to consider when selecting a fabric-to-metal glue, the types of glue available, how to apply the glue correctly, and even alternative ways to attach fabric to metal.

0 · starting up dewalt cnc machine

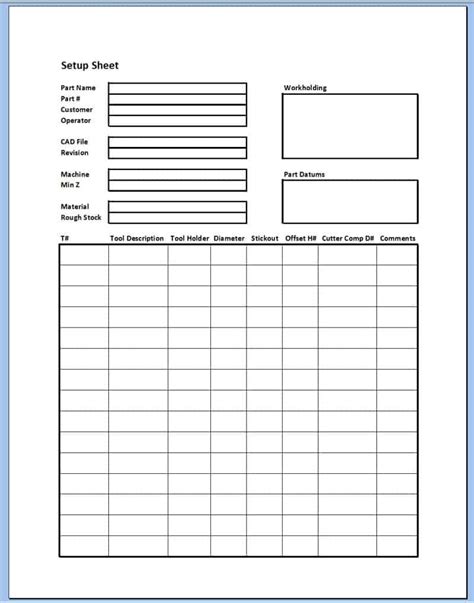

1 · cnc tool set up sheet

2 · cnc mill set up sheet

3 · cnc machines for dummies

4 · cnc machine setup sheet template

5 · cnc machine setup sheet

6 · cnc machine setup checklist

7 · cnc lathe setup sheet

Does a completely enclosed metal box with solid walls act as a Faraday cage? Everything depends on the size of the hole. It has to be smaller than any wavelength you're considering. At 1 GHz the wavelength is 30 cm and a good Faraday cage can be easily built. If you're trying to block EMPs it's harder.

In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to the first cut. The first step in setting up a CNC milling machine is to inspect the .

In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.Follow these steps to set up your SYIL CNC machine for operation: Ensure the machine is placed on a stable and level surface. Connect the machine to a power source and ensure it is properly grounded.Introduction:\ Setting up a CNC milling machine can be a daunting task, especially for beginners. However, with the right knowledge and step-by-step instructions, anyone can learn how to set . This video series is on machine setup and alignment. We will walk through all the steps needed to get your machi.

Despite appearances, [This Old Tony]’s latest series has little to do with CNC-ifying an Etch A Sketch. Although he certainly achieves that, more or less, automating the classic toy is just the. To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow.

Setting up a CNC workspace involves preparing the machine for operation. This includes cleaning the machine table, loading the appropriate tools into the tool changer or spindle, installing work-holding devices, setting tool . In this tutorial we run through setting up your first job after you have exported your Gcode file. We cover different methods to hold down your material such.

Hello everyone, welcome to At-Man Unlimited. This video series is on machine setup and alignment. We will walk through all the steps needed to get your machi.

Jessie shows us a step by step process on how to set up a 5-Axis project using the DVF 5000 from DN Solutions. He then shows us the full process of machining. And while technology has improved mightily since that seemingly ancient age, and while the costs for quick-change tooling and offline presetting systems have come down, far too many machine shops are still relying on their old-school setup procedures: tramming in their 6 .Note: If you are using a 3018 PROVer CNC, you will need to home your CNC before you will be able to jog any Axis. Zeroing your Z axis. Now you need to zero-out the Z axis in order to have your work coordinates completely set. There are two ways to do this: If you have the 3018 Pro or another CNC that does not have a Z-Probe

Tutorial for HAAS CNC Vertical Mill Part Set-up. Closed Captions available. Technical material created by Rose DeNunzio. This video is owned and copyrighted . Table Setup: Set up the machine bed or table, ensuring it is level and stable. Flat surfaces help ensure the accuracy of CNC machining. . These are the general steps on how to set up a CNC router. By following these steps and consulting the specific guidelines provided by the CNC router manufacturer, you can ensure a successful setup and .Getting Started: Machine Setup. Setting up your first CNC machine might seem daunting, but breaking it down into manageable steps can simplify the process. Step 1: Choose Your Workspace. Find a suitable location for your CNC machine. Ensure you have enough space to move around comfortably and access power outlets. Consider ventilation . How you may add a laser to your CNC machine.Very easy and quick guidance.Learn more on http://EnduranceLasers.com if you have any questions, please email: gf.

This YouTube video demonstrates how to use the VEVOR CNC 3018 Engraving Machine. Use leveling bridges or spirit level for leveling.Place the spirit level on machine.Check the level of both long and cross of machine.Loosen all the nut foundation bolt.Use the machine leveling bolt for leveling .This bolt may be with machine or leveling plates according to different machine. We have put together this video as Easel has a mandatory Machine setup process for new users and users who have upgraded their Easel driver version. As we se. For any user of a CNC, to successfully operate your machine, you must set it up for the toolpath you have created (see Fusion 360 Quick Start Guide for more about that step) by establishing where X, Y and Z are equal to Zero. Jointly, these three values establish the "origin".

CAUTION: In the next step, do not press PART ZERO SET a third time; this loads a value into the Z AXIS column. This causes a crash or a Z-Axis alarm when the program is run. Press PART ZERO SET [B] to load the value into the X Axis column. The second press of PART ZERO SET [B] loads the value into the Y Axis column.This machine can do everything a larger machine can, it just has a smaller build platform. . I have another instructable up on how to make the CAM setup for this particular model: 3D-Milling-CAM-Setup-Fusion-360. Step 1: Tool Change + .

Jaimie & Jay assemble the 1000mm X-Carve from Inventables! The X-Carve is a CNC machine that comes as a DIY kit. In this video, we walk you through our exper. In some videos, you just have to get things done. The instructions really were this simple. The thing that amazed me about Swiss machines is how rock solid they are. You can run about .0002" total tolerance on 1/2" length all friggin day long, turn it off and start it up the next day and still be within .0002" without a warm up, let's say in brass, where you don't have much tool wear. Resources for setting up a new CNC machine in Fusion Manufacture. Post Processing First, check our library of free post processors to see if there is a generic post that suits your machine. . Using 4/5 axis and your post is not set up yet? How to set up a 4/5 axis machine configuration in Fusion 360 and HSM CAM Post Processors; If you need to .

Just plug the cables in, boot up the machine, read the instructions, and start learning to use CNC to help you make parts. Sherline’s system uses Linux for the operating system and LinuxCNC (formerly EMC) for the program to run your g-code. . you will be severely limited in what you can produce with CNC machines, large or small. If you don .

starting up dewalt cnc machine

Mastering the operation of a CNC machine opens up numerous opportunities in various industries. From manufacturing intricate parts to creating prototypes, the possibilities are endless. Investing time in learning how to use a CNC machine can enhance your skills and broaden your career prospects.CNC turning machines play a crucial role in the manufacturing industry, allowing for accurate and efficient production of various components. However, to harness the full potential of these machines, proper set-up is essential. In this blog post, we will provide a comprehensive guide on how to set up a CNC turning machine.

Important safety rules for operating your MillRight CNC machine: Never place your hands near a spinning end mill or bit. . ball nose, or V bit in a size ¼” or under will work as well. This program is not set up for speed or efficiency but to check that the machine is working correctly. Your personal programs can be 7. Don't skimp on tools and toolholders. Be sure there are enough tools available to prevent delays in setup. Compared to the cost of machine downtime, tools are still a bargain. 8. Take steps to eliminate dry runs or machining of setup pieces. The time to dry run, or machine setup pieces, can be significant.In Carbide Motion, click the "Setup New Machine" button. Machine Setup Wizard. Click "Next" to begin the configuration process. Power up your machine (OPTIONAL) Select your machine type in the drop down box to show where the power switch is. Power up your machine and click "Next". Connect to your machine. Click the "Connect to Machine" button.

In this episode, Mark shows you how to properly. and accurately. set a tool length offset and a work offset. One of the most common ways to crash a machine .

The Bantam Tools Desktop CNC Milling Machine is about 80 lb. Have a friend help you unbox the machine and lift it onto your desktop. Step 1: Unbox your Desktop CNC Milling Machine. Cut and discard the straps. Open the Desktop CNC Milling Machine's box. Remove the Accessory Kit, power supply, and cables from the top tray.

vesta 860cfm 30 stainless steel under cabinet range hood

$69.99

how to set up cnc machine|cnc machines for dummies