26 gauge sheet metal thickness Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . Phones, cable boxes, computers, and tele-visions all are susceptible to interference, a condition made worse when line voltage and low voltage are run parallel through the same hole.

0 · what thickness is 26 gauge

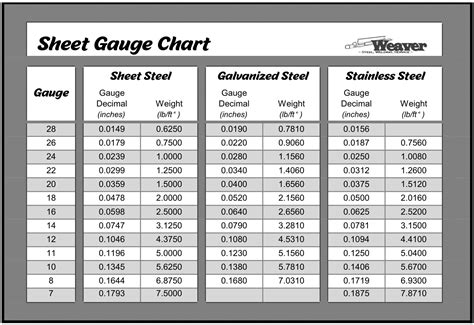

1 · steel sheet gauge thickness chart

2 · ss sheet metal gauge chart

3 · sheet metal gauge thickness chart

4 · metal gauge thickness chart

5 · how thick is 26 guage

6 · galvanized steel gauge thickness chart

7 · 26 gauge stainless steel thickness

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers .

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Pure metal / Used as an alloy element for aluminum, lead, zinc, and other .

Find the gauge to mm/inch conversion for sheet metal of different materials, including .GAUGE TO THICKNESS CHART Gauge Stainless Galvanized Sheet Steel Aluminum Fraction inches (mm) inches (mm) inches (mm) inches (mm) . 1/64 0.0156 (0.41) 0.0187 (0.47) 0.0149 . The following sheet metal gauge size reference chart gives the weight and thickness .Below you will find a chart for metal thicknesses and weights. Commonly used metals for manufacturing at our shop are: Aluminum: 0.025", 0.032", 0.040", 0.050", 0.063", 0.080", 1/8" .

what thickness is 26 gauge

Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to .

sheet metal names

A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. The higher the gauge, the thinner the sheet. Selecting the correct thickness is a critical . To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar .

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Ga. is different from inches, there is no conversion formula. Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below.GAUGE TO THICKNESS CHART Gauge Stainless Galvanized Sheet Steel Aluminum Fraction inches (mm) inches (mm) inches (mm) inches (mm) . 1/64 0.0156 (0.41) 0.0187 (0.47) 0.0149 (0.38) 0.0126 (0.32) 27 0.0172 (0.43) 0.0202 (0.51) 0.0164 (0.42) 0.0142 (0.36) 26 0.0187 (0.48) 0.0217 (0.55) 0.0179 (0.45) 0.0159 (.40)

The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number .Below you will find a chart for metal thicknesses and weights. Commonly used metals for manufacturing at our shop are: Aluminum: 0.025", 0.032", 0.040", 0.050", 0.063", 0.080", 1/8" (0.125") and 1/4" (0.25"). Cold and hot rolled steel: 16 gauge, 14 gauge, 1/8" and 1/4". Galvanized steel: 24 gauge, 20 gauge, 18 gauge and 16 gauge.Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material. A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. The higher the gauge, the thinner the sheet. Selecting the correct thickness is a critical part of .

To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar measurements—0.0478 inches or 1.214 millimeters for steel, for example. However, the gauge number, like “18” in this case, doesn’t directly relate to the actual thickness measurements.Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. Different materials with the same gauge number have different sheet thicknesses in mm. The higher the gauge number, the lower will be the sheet thickness. For example, a 16 gauge CRCA sheet metal measures 1.5 mm thickness. A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters. For example, 18 gauge steel, according to a gauge conversion chart, is 0.0478 inch or 1.214 millimeter.

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Ga. is different from inches, there is no conversion formula. Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below.

GAUGE TO THICKNESS CHART Gauge Stainless Galvanized Sheet Steel Aluminum Fraction inches (mm) inches (mm) inches (mm) inches (mm) . 1/64 0.0156 (0.41) 0.0187 (0.47) 0.0149 (0.38) 0.0126 (0.32) 27 0.0172 (0.43) 0.0202 (0.51) 0.0164 (0.42) 0.0142 (0.36) 26 0.0187 (0.48) 0.0217 (0.55) 0.0179 (0.45) 0.0159 (.40)The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number .Below you will find a chart for metal thicknesses and weights. Commonly used metals for manufacturing at our shop are: Aluminum: 0.025", 0.032", 0.040", 0.050", 0.063", 0.080", 1/8" (0.125") and 1/4" (0.25"). Cold and hot rolled steel: 16 gauge, 14 gauge, 1/8" and 1/4". Galvanized steel: 24 gauge, 20 gauge, 18 gauge and 16 gauge.Below is our best attempt to capture all of the standard gauge thickness of different materials. Be sure to check with your supplier when purchasing steel what your actual thickness is going to be, especially if you’re receiving polished or treated material.

A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. The higher the gauge, the thinner the sheet. Selecting the correct thickness is a critical part of . To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar measurements—0.0478 inches or 1.214 millimeters for steel, for example. However, the gauge number, like “18” in this case, doesn’t directly relate to the actual thickness measurements.

Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. Different materials with the same gauge number have different sheet thicknesses in mm. The higher the gauge number, the lower will be the sheet thickness. For example, a 16 gauge CRCA sheet metal measures 1.5 mm thickness.

$29.39

26 gauge sheet metal thickness|sheet metal gauge thickness chart