cnc lathe parts counter There are several ways on a Fanuc CNC to count parts, here are a few scenarios and guides. In this case the machine should count on an M30 or M02. However, some machine tool builders (MTB) like to create their own M . Outdoor Electrical Box NEMA Enclosure Weatherproof Junction Box with Fan Vent Metal Electrical Cabinet with Shelves(24x20x12”)

0 · m code for cnc parts

1 · cnc m2 counter code

Alibaba.com offers you the chance to grab some of the finest and the most durable vertical steel box at brilliant prices and never-ending deals. vertical steel box found here are very reliable, sturdy, and can be used for several purposes from storing to packaging and much more.Most homeowners going for a vertical siding style tend to opt for wood-look steel, as it comes in a variety of warm, authentic colors that match the look of natural wood. As a .

The M30 counter is most commonly used to count how many parts you've made – but are there ways to get more out of this feature? In this video, Mark teaches us a few useful "M30 tips" . The counter generally will actuate on M2 and prolly M30. The only time you should hafta add an M-code is oddball times when you want to count in a loop and want to actuate the . There are several ways on a Fanuc CNC to count parts, here are a few scenarios and guides. In this case the machine should count on an M30 or M02. However, some machine tool builders (MTB) like to create their own M .Part counting is an extremely useful data item that will enable you to monitor your throughput, quality, and much more. This article will walk you through the basics of ensuring part counting is enabled on your machines.

For a lathe, you can use this version: G10 L10 P30 U.0001 You can also use M97 calls to increase the real parts counter: First, make sure setting 118 (M99 bumps M30 counter) . Using the ability to pass an Argument to Macro Program, you could pass an argument to initialize the parts counter. For example: M101 C1000. In the above example the .

The patented Royal Rota-Rack® is an automatic accumulator that can be used with any bar-fed CNC lathe to safely collect finished parts, providing hours of highly profitable, unmanned production.

Mori Seiki NMV Programming G-codes and M-codes complete lists for cnc machinists programmers who work on Mori Seiki machining centers. Image: HEINZ BAUMGAR. Set up a simple counter using your 500 variables. You can set it up to count bars or parts which ever works. You can have a couple different counters set up. One to count the run . Are you using M99's or multiple vises or something else that's causing a part count problem? I think there's a setting that will let you use an M99 to advance the part counter. I .The M30 counter is most commonly used to count how many parts you've made – but are there ways to get more out of this feature? In this video, Mark teaches us a few useful "M30 tips" that you may not know about – like using two counters at the same time, and how to use the counter in programs that loop.

The counter generally will actuate on M2 and prolly M30. The only time you should hafta add an M-code is oddball times when you want to count in a loop and want to actuate the counter and not end the program. If not - that is editable in the params - which code will toggle it. There are several ways on a Fanuc CNC to count parts, here are a few scenarios and guides. In this case the machine should count on an M30 or M02. However, some machine tool builders (MTB) like to create their own M-Code to count with. Below you can find out if your machine counts on M30 / M02 or just the MTB's M-Code.Part counting is an extremely useful data item that will enable you to monitor your throughput, quality, and much more. This article will walk you through the basics of ensuring part counting is enabled on your machines. For a lathe, you can use this version: G10 L10 P30 U.0001 You can also use M97 calls to increase the real parts counter: First, make sure setting 118 (M99 bumps M30 counter) is ON.

Using the ability to pass an Argument to Macro Program, you could pass an argument to initialize the parts counter. For example: M101 C1000. In the above example the Target Number of 1000 is passed to the Macro. In this case the structure of the Macro Program would set the System Variable #3902 to 1000 and #3901 to Zero.

The patented Royal Rota-Rack® is an automatic accumulator that can be used with any bar-fed CNC lathe to safely collect finished parts, providing hours of highly profitable, unmanned production.Mori Seiki NMV Programming G-codes and M-codes complete lists for cnc machinists programmers who work on Mori Seiki machining centers. Image: HEINZ BAUMGAR. Set up a simple counter using your 500 variables. You can set it up to count bars or parts which ever works. You can have a couple different counters set up. One to count the run and one to count the day. Or what ever you might want. Note..if you are able to use the parts counter on the offset/setting screen, it will depend on the manufacturer's choice of M code as to what triggers the count. As M-Man says, use M54 (which may or may not be right for your machine).

The M30 counter is most commonly used to count how many parts you've made – but are there ways to get more out of this feature? In this video, Mark teaches us a few useful "M30 tips" that you may not know about – like using two counters at the same time, and how to use the counter in programs that loop. The counter generally will actuate on M2 and prolly M30. The only time you should hafta add an M-code is oddball times when you want to count in a loop and want to actuate the counter and not end the program. If not - that is editable in the params - which code will toggle it. There are several ways on a Fanuc CNC to count parts, here are a few scenarios and guides. In this case the machine should count on an M30 or M02. However, some machine tool builders (MTB) like to create their own M-Code to count with. Below you can find out if your machine counts on M30 / M02 or just the MTB's M-Code.Part counting is an extremely useful data item that will enable you to monitor your throughput, quality, and much more. This article will walk you through the basics of ensuring part counting is enabled on your machines.

For a lathe, you can use this version: G10 L10 P30 U.0001 You can also use M97 calls to increase the real parts counter: First, make sure setting 118 (M99 bumps M30 counter) is ON. Using the ability to pass an Argument to Macro Program, you could pass an argument to initialize the parts counter. For example: M101 C1000. In the above example the Target Number of 1000 is passed to the Macro. In this case the structure of the Macro Program would set the System Variable #3902 to 1000 and #3901 to Zero.

The patented Royal Rota-Rack® is an automatic accumulator that can be used with any bar-fed CNC lathe to safely collect finished parts, providing hours of highly profitable, unmanned production.

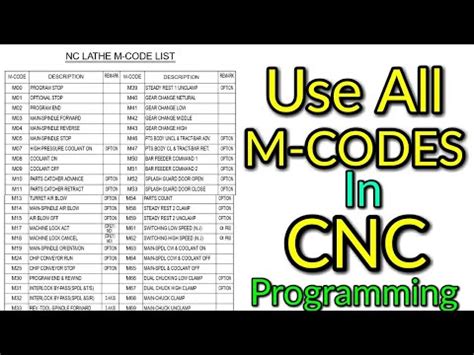

Mori Seiki NMV Programming G-codes and M-codes complete lists for cnc machinists programmers who work on Mori Seiki machining centers. Image: HEINZ BAUMGAR.

Set up a simple counter using your 500 variables. You can set it up to count bars or parts which ever works. You can have a couple different counters set up. One to count the run and one to count the day. Or what ever you might want.

precision sheet metal parts supplier

m code for cnc parts

cnc m2 counter code

El administrador del sitio, ( en lo sucesivo “LA EMPRESA”) con domicilio para .

cnc lathe parts counter|m code for cnc parts