cnc machine geometrical test These basic three types of accuracy of CNC machine tools are complemented by other types of accuracy, namely positioning accuracy, interpolation accuracy, volumetric accuracy, and thermal expansion. Stainless Steel Masala Dabba, Spice box, 7 Compartments with Lid, 8 inch Diameter

0 · Studies and Practice of Geometrical Test Procedures

1 · Mastering CNC Machine Geometrical Test Charts: A

2 · Improving CNC Machine Tool Geometric Precision Using

3 · ISO 230

4 · Geometric error measuring, modeling, and compensation for

5 · Geometric Accuracy, Volumetric Accuracy and

6 · Geometric Accuracy of Machine Tools

7 · Geometric Accuracy Inspection Of CNC Machining

8 · Calibration and Checking the Geometrical Accuracy of a CNC

9 · (PDF) Studies and Practice of Geometrical Test

Get the best deals on Vintage Tool Box when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

Studies and Practice of Geometrical Test Procedures

These basic three types of accuracy of CNC machine tools are complemented by other types of accuracy, namely positioning accuracy, interpolation accuracy, volumetric accuracy, and thermal expansion. Specific methods for geometric errors measurement and identification are discussed. The methods for geometric error modeling and sensitivity analysis are reviewed. .

Mastering CNC Machine Geometrical Test Charts: A

In this blog post, we will explore the importance of test charts in optimizing the accuracy and performance of CNC machines. Test charts are essential tools used by manufacturers, .

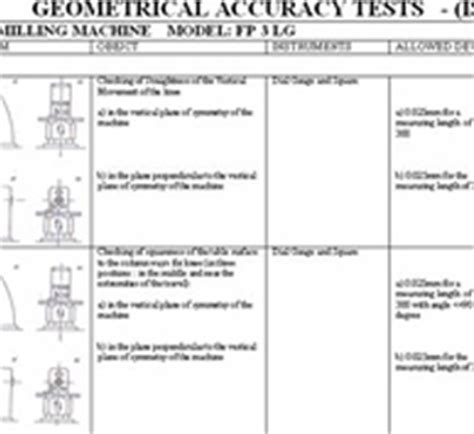

Therefore, increasing the geometric accuracy is a feature of the machine that needs to be constantly improved. This chapter presents geometric accuracy tests, .

Synergy when evaluating geometric and positioning accuracy using a laser tracker [9]. Principle of measurement with LaserTRACER [etalon]. Relationships between individual accuracies of a CNC.

ISO 230-1:2012 specifies methods for testing the accuracy of machine tools, operating either under no-load or under quasi-static conditions, by means of geometric and .

This paper puts forth some basic Geometrical Tests performed on SB CNC 60 Lathe Machine Tool unit, identifying major deviations measurements and reconditioning the machine parts.A quick accuracy test of a CNC machine-tool can be performed with the Ballbar QC10 device; calibration and parameter correction on the CNC controller can be done with a test-result .

This paper puts forth some basic Geometrical Tests performed on SB CNC 60 Lathe Machine Tool unit, identifying major deviations measurements and reconditioning the .

Improving CNC Machine Tool Geometric Precision Using

With the ever increasing demands for higher and higher accuracy on modern CNC equipment, the manufacturing processes for machining and assembling the structural . These basic three types of accuracy of CNC machine tools are complemented by other types of accuracy, namely positioning accuracy, interpolation accuracy, volumetric accuracy, and thermal expansion. Specific methods for geometric errors measurement and identification are discussed. The methods for geometric error modeling and sensitivity analysis are reviewed. The advancements of geometric error compensation techniques and .In this blog post, we will explore the importance of test charts in optimizing the accuracy and performance of CNC machines. Test charts are essential tools used by manufacturers, engineers, and operators to ensure precise and consistent machining results.

Therefore, increasing the geometric accuracy is a feature of the machine that needs to be constantly improved. This chapter presents geometric accuracy tests, instrumentation and examples of selected procedures to increase the geometric accuracy of CNC machine tools . Synergy when evaluating geometric and positioning accuracy using a laser tracker [9]. Principle of measurement with LaserTRACER [etalon]. Relationships between individual accuracies of a CNC. ISO 230-1:2012 specifies methods for testing the accuracy of machine tools, operating either under no-load or under quasi-static conditions, by means of geometric and machining tests. The methods can also be applied to other types of industrial machines.

This paper puts forth some basic Geometrical Tests performed on SB CNC 60 Lathe Machine Tool unit, identifying major deviations measurements and reconditioning the machine parts.

A quick accuracy test of a CNC machine-tool can be performed with the Ballbar QC10 device; calibration and parameter correction on the CNC controller can be done with a test-result analysis from the very accurate ML10 laser device.

This paper puts forth some basic Geometrical Tests performed on SB CNC 60 Lathe Machine Tool unit, identifying major deviations measurements and reconditioning the machine parts. The main objective of running such tests is to prevent breakdown of the machine and ensure safety working when handling older and heavier conventional machines. With the ever increasing demands for higher and higher accuracy on modern CNC equipment, the manufacturing processes for machining and assembling the structural components are an increasingly important factor in establishing a geometrically correct machine tool. These basic three types of accuracy of CNC machine tools are complemented by other types of accuracy, namely positioning accuracy, interpolation accuracy, volumetric accuracy, and thermal expansion. Specific methods for geometric errors measurement and identification are discussed. The methods for geometric error modeling and sensitivity analysis are reviewed. The advancements of geometric error compensation techniques and .

In this blog post, we will explore the importance of test charts in optimizing the accuracy and performance of CNC machines. Test charts are essential tools used by manufacturers, engineers, and operators to ensure precise and consistent machining results. Therefore, increasing the geometric accuracy is a feature of the machine that needs to be constantly improved. This chapter presents geometric accuracy tests, instrumentation and examples of selected procedures to increase the geometric accuracy of CNC machine tools .

Synergy when evaluating geometric and positioning accuracy using a laser tracker [9]. Principle of measurement with LaserTRACER [etalon]. Relationships between individual accuracies of a CNC. ISO 230-1:2012 specifies methods for testing the accuracy of machine tools, operating either under no-load or under quasi-static conditions, by means of geometric and machining tests. The methods can also be applied to other types of industrial machines. This paper puts forth some basic Geometrical Tests performed on SB CNC 60 Lathe Machine Tool unit, identifying major deviations measurements and reconditioning the machine parts.A quick accuracy test of a CNC machine-tool can be performed with the Ballbar QC10 device; calibration and parameter correction on the CNC controller can be done with a test-result analysis from the very accurate ML10 laser device.

arch sheet metal

This paper puts forth some basic Geometrical Tests performed on SB CNC 60 Lathe Machine Tool unit, identifying major deviations measurements and reconditioning the machine parts. The main objective of running such tests is to prevent breakdown of the machine and ensure safety working when handling older and heavier conventional machines.

ISO 230

Geometric error measuring, modeling, and compensation for

Geometric Accuracy, Volumetric Accuracy and

The shelf brackets go perfectly in a pastoral or industrial home decor scheme that can be installed in kitchen, bathroom, bookroom, .

cnc machine geometrical test|Geometric Accuracy, Volumetric Accuracy and