applications of nc cnc machine CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. . Most cnc milling parts products boast high quality and low MOQs with direct prices .

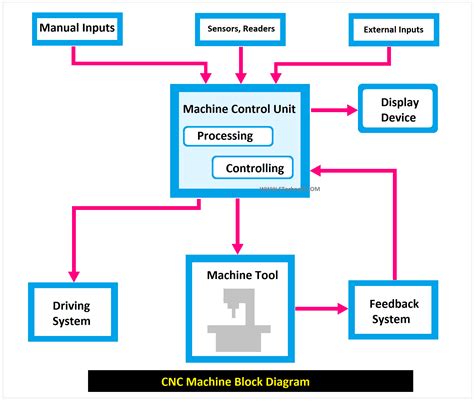

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

Buy a wholesale cnc precision milling milled parts metal machined to help you make customized parts with a neat finishing. Visit Alibaba.com for cnc milling machines that suit your needs and budget.Custom CNC milling for cost-effective milled parts and prototypes. From copper to steel milling, choose from 50+ materials. Free shipping! Quality Guaranteed!

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They .CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. .

Applications of NC Machine. NC machines find extensive utilisation in the metal-cutting industry and excel in producing the following types of products: Parts with intricate contours. Parts requiring close tolerances and .CNC machines are typically designed with protective structures, reducing operator contact with the machines and lowering workplace safety risks. Operators can monitor the machining . Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC .CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots .

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They decrease waste, improve .CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling) Applications of NC Machine. NC machines find extensive utilisation in the metal-cutting industry and excel in producing the following types of products: Parts with intricate contours. Parts requiring close tolerances and excellent repeatability. Parts that would necessitate expensive jigs and fixtures if produced on conventional machines.

CNC machines are typically designed with protective structures, reducing operator contact with the machines and lowering workplace safety risks. Operators can monitor the machining process within a safe distance, avoiding direct contact with sharp tools and harmful coolants. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.

CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future.CNC Lathe machine Application. CNC lathe machine usually is two types. Wood lathe, metal-metal lathe. The rotational speed of the wood lathe is higher than the metal lathe. The following are the primary application of the CNC lathe machine: Facing: Facing process is a process where we remove the materials to make a flat surface. in this post, you’ll learn what is NC machine and its working, types of NC system, basic components, NC coordinate system, application, advantages and more with PDF download. In conventional machine parameters like feed, depth of .

Let’s navigate through the different types of CNC machining and uncover the unique attributes and applications of each. Milling: Milling machines use rotary cutters to remove material. They’re versatile and can produce everything from simple shapes to complex geometries. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They decrease waste, improve .

CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling)

Applications of NC Machine. NC machines find extensive utilisation in the metal-cutting industry and excel in producing the following types of products: Parts with intricate contours. Parts requiring close tolerances and excellent repeatability. Parts that would necessitate expensive jigs and fixtures if produced on conventional machines.CNC machines are typically designed with protective structures, reducing operator contact with the machines and lowering workplace safety risks. Operators can monitor the machining process within a safe distance, avoiding direct contact with sharp tools and harmful coolants.

Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.

CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future.CNC Lathe machine Application. CNC lathe machine usually is two types. Wood lathe, metal-metal lathe. The rotational speed of the wood lathe is higher than the metal lathe. The following are the primary application of the CNC lathe machine: Facing: Facing process is a process where we remove the materials to make a flat surface. in this post, you’ll learn what is NC machine and its working, types of NC system, basic components, NC coordinate system, application, advantages and more with PDF download. In conventional machine parameters like feed, depth of .

steel junction box sizes

schematic diagram of cnc machine

products made by milling machine

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

applications of nc cnc machine|computer numerical control cnc machines