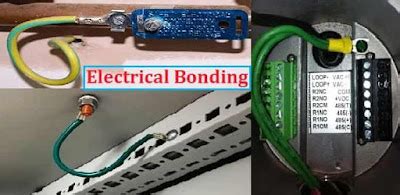

bonding electrical boxes Bonding joins non-current metal parts of the system together to provide a low-impedance path for current to flow from these metal components back to the source should they become energized during a ground fault. This . Enterprise UK has more than 25 years’ experience when it comes to delivering high-quality sheet metal fabrications. We can deliver precision sheet metal work for all kinds of industries.

0 · types of electrical bonding

1 · metal electrical box bonding

2 · how to use electrical bonding

3 · how to bond metal boxes

4 · how does electrical bonding work

5 · examples of electrical bonding

6 · electrical bonding explained

7 · bonding for electrical equipment

The junction box EW-RS910 by Shimano is a Di2 connection point, also called junction A, which is installed internally. You can choose between the handlebar tube and the frame or down tube as mounting positions. The junction has two E-Tube connections and one charging connection.

Basically, grounding is connecting to the earth. The Code defi nes “bonded” or “bonding” as connected (connecting) to establish electrical continuity and conductivity. Let’s examine these .

In this video I will show you how to correctly bond a metal 4 square box. I want to be clear that you need to use a separate ground screw and a wire that i.

types of electrical bonding

metal electrical box bonding

Bonded (bonding) is defined in NEC Article 100 as: Connected to establish electrical continuity and conductivity. See Figure 1 below which shows two metal boxes bonded together . Bonding joins non-current metal parts of the system together to provide a low-impedance path for current to flow from these metal components back to the source should they become energized during a ground fault. This . Learn about the general requirements for grounding and bonding in line with the NEC 2023. The purpose of grounding is the safety of people and property. Grounding and bonding limit overvoltages, stabilize the voltage to .To safely conduct any fault current likely to be imposed, electrical equipment must have bonding. This is often where the fun begins. The metal parts of raceways and/or enclosures containing .

Bonding is a means of providing electrical continuity between metallic objects. Simple definition, right? What’s not always simple is correctly applying the NEC requirements, some of which changed with the 2011 revision. Bonding is connecting metal parts together that are not supposed to carry current to create an electrically conductive path to the established grounded system so that the . The National Electrical Code (NEC) lists eight specific methods to make grounding and bonding connections in Sec. 250.8. Failure to install these connections properly can result in shock, fire, or, most certainly, power quality .While grounding and bonding might seem like the same thing, they have some very important differences. Electrical bonding is the practice of connecting metallic objects that may be exposed to electrical faults or induced voltages to the grounding conductor.

Basically, grounding is connecting to the earth. The Code defi nes “bonded” or “bonding” as connected (connecting) to establish electrical continuity and conductivity. Let’s examine these two important integral parts of electric wiring closer in detail.In this video I will show you how to correctly bond a metal 4 square box. I want to be clear that you need to use a separate ground screw and a wire that i. Bonded (bonding) is defined in NEC Article 100 as: Connected to establish electrical continuity and conductivity. See Figure 1 below which shows two metal boxes bonded together with the metal raceway installed between the two boxes.

Bonding joins non-current metal parts of the system together to provide a low-impedance path for current to flow from these metal components back to the source should they become energized during a ground fault. This path allows the overcurrent protective device (fuse or circuit breaker) to operate and clear the fault. Learn about the general requirements for grounding and bonding in line with the NEC 2023. The purpose of grounding is the safety of people and property. Grounding and bonding limit overvoltages, stabilize the voltage to the ground during regular functioning, and ease the proper operation of circuit breakers and fuses.To safely conduct any fault current likely to be imposed, electrical equipment must have bonding. This is often where the fun begins. The metal parts of raceways and/or enclosures containing service conductors must be bonded together [250.92 (A)]. Use bonding jumpers around reducing washers and ringed knockouts for service raceways.

Bonding is a means of providing electrical continuity between metallic objects. Simple definition, right? What’s not always simple is correctly applying the NEC requirements, some of which changed with the 2011 revision. Bonding is connecting metal parts together that are not supposed to carry current to create an electrically conductive path to the established grounded system so that the overcurrent protective device (OCPD) will open. Now, let’s take a .

how to use electrical bonding

how to bond metal boxes

how does electrical bonding work

examples of electrical bonding

electrical bonding explained

Steel U-Channel Post Driver. Find ultra durable u-channel posts, brackets & mounting hardware all made in the USA. Most orders ship the same day, order online today.

bonding electrical boxes|how does electrical bonding work