drawing metal sheet Unlock the secrets to precise fabrication with our expert guide on detailing sheet metal shop drawings. Enhance accuracy and efficiency in your projects. Read more! Junction boxes, with blank covers are allowed above a suspended ceiling as it is not considered a closed space. The wires that are loose and wirenuted need to be put in a j-box. Also, clamps need to be used at each wire going into a j-box.

0 · sheet metal drawings with gd&t

1 · sheet metal drawing templates

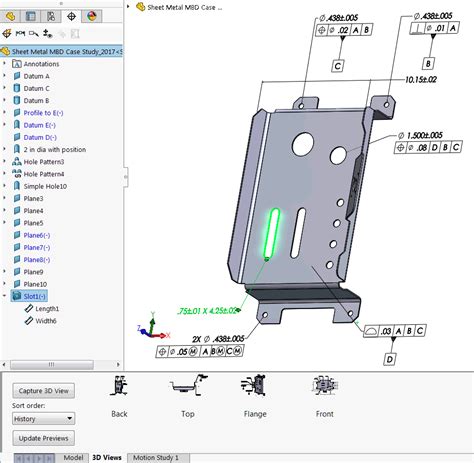

2 · sheet metal drawing in solidworks

3 · sheet metal drawing examples

4 · sheet metal basic drawing

5 · sheet metal 3d sketch solidworks

6 · metal sheet mechanical drawings

7 · basics of sheet metal design

Online Metals has copper for sale at great prices and without the hassle of shopping around. You can conveniently price and order what you need online or call us for a quote today. What copper sheet is best for forming?

sheet metal drawings with gd&t

This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad .

sheet metal drawing templates

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, .

Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of . Unlock the secrets to precise fabrication with our expert guide on detailing sheet metal shop drawings. Enhance accuracy and efficiency in your projects. Read more! 5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. .

Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various .

These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming .In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency.

sheet metal drawing in solidworks

sheet metal drawing examples

junction box above residential main panel

A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.

This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad benefits.

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this information requires a series of . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information.

Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of sheet metal components, deep drawing is often used for the processing of various cylindrical parts, hemispheres and parabolic heads of larger size or thicker material. Unlock the secrets to precise fabrication with our expert guide on detailing sheet metal shop drawings. Enhance accuracy and efficiency in your projects. Read more!

5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. List part numbers, not just the part name. Part names are great, but it’s helpful to provide part numbers, too. Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.

In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency.A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles. This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad benefits.

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this information requires a series of . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information. Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of sheet metal components, deep drawing is often used for the processing of various cylindrical parts, hemispheres and parabolic heads of larger size or thicker material.

Unlock the secrets to precise fabrication with our expert guide on detailing sheet metal shop drawings. Enhance accuracy and efficiency in your projects. Read more!

5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. List part numbers, not just the part name. Part names are great, but it’s helpful to provide part numbers, too.

Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.

sheet metal basic drawing

sheet metal 3d sketch solidworks

Find farm fields and homesteads to metal detect and best approach how to detect them. I have interviewed Brian for best practices, detecting homesteads, fields and XP settings.

drawing metal sheet|sheet metal basic drawing