sheet metal hole distance from bend 3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced . With complete wholesale cnc aluminum parts production lines and experienced employees, can independently design, develop, manufacture, and test all products in an efficient manner. Throughout the whole process, our QC professionals will .

0 · sheet metal gusset design guidelines

1 · sheet metal bending radius chart

2 · sheet metal bending chart

3 · sheet metal bend relief guidelines

4 · sheet metal bend deduction chart

5 · minimum flange length sheet metal

6 · maximum thickness sheet metal bending

7 · bend allowance chart

CNC Milling is an automated machining process used to manufacture 2D and 3D cnc parts by removing material from raw stock. Workshops use CNC milling machines to save time and improve manufacturing productivity.

sheet metal gusset design guidelines

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius.Sheet Metal Bend allowance and bend deduction are directly related to each .Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. .

3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced .

Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. When the sheet metal bend is aligned with the direction of the .

The following table outlines the minimum distance guidelines between a hem and other features such as holes and bends in sheet metal parts. These distances, calculated based on material thickness and the hem's .Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it can lead to metal deformation. It is recommended that the minimum distance between two extruded holes should . To calculate how close a hole can be to a bend, you need to use a different formula. In most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may increase .

To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple .

To ensure successful bending, it is recommended to place holes away from bends at a distance of at least 2.5 times the material’s thickness (T) plus the bend radius (R). For slots, it is recommended to position it at least 4 times the .General Tolerances. If a drawing or specification sheet has not been provided by the customer, Xometry will manufacture the product from the model to the specifications listed below: .

Sheet Metal Material Thickness Range. Because sheet metal parts are manufactured from a single sheet of metal, the part must maintain uniform wall thickness. Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.250 in. . Minimum distance between the bend and hole (Fig. 2) When a workpiece is to be formed, minimum hole size relates to material thickness and bend radius. Maintaining a minimum distance between the bend line and the .Bends are the most typical feature of sheet metal parts and can be formed by a variety of methods and machines which negate the absolute need for some of the below tips. . From edge to extruded hole, distance should be at least 3 times material thickness. From bend to extruded hole, distance should be 3 times material thickness plus bend radius. For hardware insertion, holes must be at least the minimum distance from center of bend to center of hardware insertion hole . of the flange. Be sure to set up your sheet metal rules using our effective bend radii and bend deduction values. These specs can all be found in the Material Details and at the bottom of our bending calculator page.

The minimum distance that holes should be placed from a bend is a function of the material thickness, bend radius, and the hole’s diameter. Holes should be at least 2.5 times the material . Minimum Distance Guidelines* Between hole and a bend: ±2.5 times the material length + bend radius: Between a slot and a bend: . Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material thickness and .

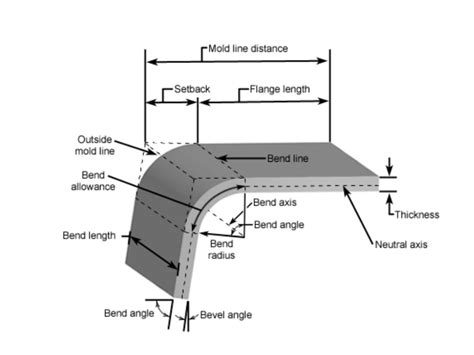

sheet metal bending radius chart

I've always eyeballed the distance from a hole to a bend. But I feel like that rule of thumb should be based on bend radius, material thickness, and measured from the tangent - not the bend line. For instance, there's no way I could put a 3mm hole only 9mm from the bend line on a part with a 20mm bend radius. Special processing when the hole is close to the bend. If the distance between the closest hole to the bend line and the bent edge is less than the minimum required distance, deformation may occur after bending. To meet the product requirements, you can refer to Table 1-15 for potential solutions.Center-to-center distance Center-to-bend distance SHEET METAL GUIDE V2.2 — TOLERANCES. Hems Hems are folds to the edge of a part to create a rounded, safe edge. Hems may be open, flat, or tear-dropped, and . Hole-to-bend distance Hole-to-edge distance Slot-to-bend distance Slot-to-edge distance SHEET METAL GUIDE V2.2 — TOLERANCES. Notches . The distance from the mold point to the bend tangent. . Sight Line. A mark on a flat sheet of metal set even with the nose of the radius bar or a cornice brake. K - factor. A number used in sheet metal work to determine the setback for bend angles other than 90 degrees. Relief hole. A hole drilled at the point at which two bend points meet .

The sheet metal thickness is 0.08", bend radius is 0.05". Reply reply . The rule of thumb is minimum distance from outside edge of a hole to the inside material face is equal to 2 times the material thickness plus the bend radius. Reply reply Joaquin2071 .

Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”. Notching is a shearing process that removes a section from the outer edge of the part. Distortion may occur if the distance between the notches and the bend is too small. To avoid this, the notch-to-bend distance should be at least 3 times the sheet thickness plus the bend radius. Notches must be at least 3.175 mm away from each other.need help manufacturing sheet metal? want to post your fabrication for all to updoot? come to r/sheetmetal to discuss all things sheet metal. Design, Fabrication, Installation. . This will minimize the hole distortion. Reply reply jikla_93 • Or just design it so the holes are the appropriate distance from the bend radius Reply .Small holes in sheet metal can be punched or can be laser cut, depending on the equipment used for punching. As general guideline suggests , hole diameter equal to sheet thickness can be punched. . Hole distance to bend. Hole .

2-3 inches with 5/16" bent plate might actually be your problem. Your bend radius with two bends is something like half of your length measurement. The following formula calculates the minimum distance from the bend at which you can punch or cut a hole, Distance (D) = Sheet Metal Thickness (t) + Bend Radius (ir) + Diameter of The Hole. So, from the formula, it is clear .

Notching is a shearing process that removes a section from the outer edge of the part. Distortion may occur if the distance between the notches and the bend is too small. To avoid this, the notch-to-bend distance should be at least 3 times the sheet thickness plus the bend radius. Notches must be at least 3.175 mm away from each other.The parts quoted were two bend sheet metal channels with holes in the top for slugs to weld to. Two parts needed to align together but overall channel dimensions has a bit of forgiveness in fit. Hole dimensions given from the final bent part. They chose to bend the part and machine the holes after since hole locations needed to be accurate As shown in the table above, the more times the sheet metal is bent, the greater the bending tolerance becomes. This makes it difficult to maintain the accuracy of the dimensions of the multiple bends in the sheet metal. This is why screw holes, pull holes, and self-rivet holes on sheet metal tend to be misaligned after bending.

Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Minimum Distance from Extruded Hole to Part Edge.DISCLAIMER:Do not us.

I have some 0.015" sheet metal that I need to bend into a near circle (5" ID) - that I'm looking to bolt onto a cylindrical surface (5" OD) conformally. I am looking to pre-drill out the holes while it is flat, bend it, and bolt it in place - the cylinder has bolt holes at 0,90,270,180 degrees.

Minimum Distance from Extruded Hole to Bend A certain distance must be maintained between extruded hole to bend to avoid metal deformation and fracturing. It is recommended that the minimum distance between extruded hole and bend should be three times the thickness of sheet metal plus bend radius. t = Sheet metal thickness Minimum hole diameter: Avoid holes smaller than the thickness of the sheet metal; smaller holes are harder to punch cleanly and may require secondary processes. Avoid distortion: If holes are too close to a bend, distortion may occur. Ensure that holes are positioned at a sufficient distance from bends and edges to maintain structural integrity. 6. • Provide strong threads in metal as thin as .012”/0.3 mm. • Installs into a plain, round hole. • Installed using any parallel acting squeezing force. • Provide high pushout and torque-out resistance. • Do not require special hole preparation, such as chamfering and deburring. • Reverse side of metal sheet remains flush.Study with Quizlet and memorize flashcards containing terms like Bend Radius, Measuring the size of the bend, the diameter is and more. . Aircraft Sheet Metal (Bending) Flashcards; Learn; Test; Match; Q-Chat; Get a hint . Is considered to be the amount of material in the bend or the distance from one bend tangent line to the next bend .

All holes and cutouts are at least 50% material thickness for laser cut parts; All holes and cutouts are no less than 0.070” for most waterjet cut parts; All holes and cutouts are no less than 0.125” for all CNC routed parts; File is built at a 1:1 scale, preferably in inch or mm units; All objects are on the same layer

Chuanghe Fastener Co., Ltd is a professional manufacturing enterprise, which is engaged in the design and development of wholesale cnc aluminum parts and production of precision metal parts.

sheet metal hole distance from bend|sheet metal gusset design guidelines