sheet metal fabrication tolerances Proper tolerancing for sheet metal bending jobs is important for making your designs ready for manufacturing. This post will briefly explain where the variations come from, and what the holdable tolerances could be for usual shop floor .

Metal enclosures are the traditional choice and are widely used in industrial settings. They are typically made from stainless steel, aluminum, or coated steel. The primary advantages are their durability and high resistance .

0 · steel thickness tolerance chart

1 · standard sheet metal tolerances chart

2 · sheet thickness tolerance chart

3 · sheet metal tolerances pdf

4 · sheet metal tolerances chart

5 · sheet metal thickness tolerance chart

6 · sheet metal gauge tolerance chart

7 · sheet metal dimensioning standards

In most cases you don’t need a special junction box for your dishwasher; all you need is a dedicated outlet. Some dishwasher brands will require that you use their own junction box so you should check the .

There are three types of sheet metal tolerances: Material, Dimensional, and Geometric. We work with three types of tolerances: Dimensional tolerances: These refer to the variations that are allowed in a part’s physical dimensions. If a piece should be 10 cm long, the patience may .

The manufacturing process used for specific features in sheet metal fabrication impacts tolerances. While features located on the same .When designing parts with some type of bend with a standard bend radius, sheet metal . Sheet metal tolerances are the maximum allowable dimension deviation during .

We frequently receive RFQs for parts with tolerances that exceed what is .Proper tolerancing for sheet metal bending jobs is important for making your designs ready for manufacturing. This post will briefly explain where the variations come from, and what the holdable tolerances could be for usual shop floor .Future of tolerances in sheet metal fabrication. The future of tolerances in sheet metal fabrication is moving towards greater precision and efficiency. We anticipate the following trends: AI and Machine Learning: AI and machine . Sheet Metal Tolerances. Many engineers misunderstand sheet metal tolerancing—and for a good reason. Engineering curriculums are often skewed toward CNC machining and 3D printing, leaving engineers with a gap .

Unlock the secrets to mastering sheet metal tolerances and ensure precision in your manufacturing processes. Explore the key factors that contribute to top-notch engineering results. . My extensive experience has allowed me . Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. Ensuring CAD designs are aligned with Design for Manufacturing (DFM) standards is pivotal in establishing realistic and attainable tolerances, taking into account the .Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, the game-changing design tool for . Fabrication Tolerances for Dimensional Variance in Sheet Metal and Machined Parts. Bending Tolerances .

Even though the term is used all the time, the reality of manufacturing tolerances can get quite complicated depending on the process in question. This post will compare machining, 3D printing, and sheet metal processes and how they affect achievable tolerances. Sheet Metal Fabrication vs. Machining vs. 3D Printing TOLERANCES FOR FABRICATION OF STEEL STRUCTURES 0. F 0 R E M’ 0 R D 0.1 This Indian Standard was adopted by the Indian Standards Institution on 27 February 1974, after the draft finalized by the Structural Engineering Sectional Committee had been approved by the Structural and Metals Division Council and the Civil Engineering Division . What’s considered a “standard” tolerance differs in precision machining and sheet metal fabrication. A standard tolerance for precision machined parts is +/- 0.005.” A standard tolerance for sheet metal fabricated parts is much looser, ranging from +/- 0.02” to +/- 0.03.” Tolerances can also vary within parts. Sheet metal tolerances allow engineers to innovate within specific parameters to meet or exceed production goals. Contact KRYTON Engineered Metals for more information on domestic fabrication and sheet metal tolerances. Learn to innovate within your industry while adhering to production standards and project guidelines.

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. . liquids, and even sound. Perforated sheet metal is most commonly used for ventilation and filtering. Stocked Perforated Sheet Metal. Aluminum: Specified Thickness: Tolerance: 20 Gauge: 0.032" | 0.81 mm: ± 0. .

7 Recommended Default Sheet Metal Tolerances; 8 Metal Fabrication FAQ. 8.0.1 What does metal fabrication involve, . Precision sheet metal fabrication is a versatile manufacturing process used to create a wide range of components and products with high accuracy and consistency. A CAD jockey who understands metal fabrication makes better decisions in applying CAD tools. Let’s focus on the accuracy of things made from rolled sheet stock. By Gerald . can routinely have tighter tolerances than precision sheet metal parts (typical tolerance of ±0.010 in.). Figure 1b This is an example of a rectangular cutout corner .Tolerances for laser cutting, water jet cutting, forming, weldments, etc. Skip to content. . Welding is a metal fabrication process that joins metal components by using high heat to melt the base pieces together. After cooling, the two components are fused. . 2 Place Dimension: ±0.06″ [1.524mm] 3 Place Dimension: ±0.03″ [0.762mm .

steel thickness tolerance chart

Now consider 16-gauge mild steel. The sheet has a nominal thickness of 0.059 in., an upper limit of 0.0648 in., and a lower limit of 0.0548 in., giving us a range of 0.010 in. Add this to the 0.002-in. depth-of-penetration variation noted earlier, and .Tolerances of Machined and Sheet Metal Parts Xometry's Manufacturing Partner Network makes thousands of machines available to make your part at the click of a mouse. Since the minimum requirement to machine a part is a solid CAD file, we offer these general tolerances and guidelines (also found in our Manufacturing Standards ).

They define the permissible limits of variation in a physical dimension which is a very crucial quality metric in sheet metal fabrication drawings. The International Organization for Standardization (ISO) provides .

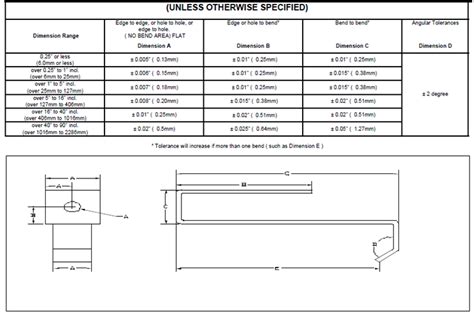

For example, the manufacturer recommends ISO 2768-mk for sheet metal parts and ISO 2768-fh for machined components. In the above example, “m” and “k” have defined the tolerance class. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose.Sheet Metal Fabrication Tolerances - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document from Vista Industrial Products provides default sheet metal tolerances in millimeters and inches for various dimensions of sheet metal parts, including tolerances for distances between holes, edges, bends, and across bends.Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. . It's also important when working with sheet metal that you factor in finish tolerances. For example, if you add a finish such as powdercoat, you add more thickness - this should be factored into your design at .

Table of Contents. 1 How Powder Coating Adds Thickness to a Metal Fabricated Part. 1.1 Adjusting tolerances to account for powder coating buildup ; 2 Proactive Designs Pave the Way for Optimal Powder Coating Results; 3 Recommended Default Sheet Metal Tolerances; 4 Sheet Metal Powder Coating Tolerance FAQ. 4.0.1 How does powder coating affect the . “Having a handy guide to compare your called tolerances will profoundly affect your production,” Benson explained. By a “handy guide,” Benson means a guideline specifying reasonable tolerances for a formed part, both for linear and angular dimensions, as shown in Figure 1.. “You will no longer be making unreasonable demands, and no longer will you have . If general tolerances in accordance with ISO 2768 shall apply, ISO 2768 followed by the tolerance class (Ex: ISO 2768-m) shall be indicated in or near the title block. . Hello! I'm Austin Peng. I manage a factory that specializes in CNC machining, injection molding, and sheet metal fabrication for small quantity production and rapid .

Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. . It offers tighter tolerances and a more refined look, making it suitable for more visible applications. It is also stronger than hot rolled steel due to the additional processing. Galvanized Steel. Sheet Metal Fabrication Tolerances Sheet metal tolerancing is a common topic of discussion we have with design engineers and OEMs looking to develop and source new custom parts. Understanding what tolerances your sheet metal supplier can maintain leads to better collaboration and design for manufacturability (DFM).General Tolerances ISO 2768-1 ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). . Vacuum Casting, Injection Molding, Sheet Metal Fabrication. Permissible deviations in mm for ranges in nominal lengths Tolerance Class . Common Standards for Dimensional tolerances. We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These standards serve as a guide to ensure consistency in production regardless of the project’s complexity.. It’s not just about compliance; it’s about .

One of the most critical aspects of sheet metal fabrication is managing tolerances, which are the permissible variations in a part's dimensions. Tolerances are essential for ensuring that parts fit together correctly, function as intended, and meet required quality standards. Without precise tolerance control, manufacturers can encounter significant issues such as misalignments, .

standard sheet metal tolerances chart

custom welding metal fabrication

customized 2u server metal enclosure with paint ce

sheet thickness tolerance chart

Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more

sheet metal fabrication tolerances|sheet metal tolerances chart