sheet metal design for manufacturability Metal sheet manufacturers spend 30% to 50% of their time fixing errors and almost 24% of those errors are related to manufacturability. The reason is usually the wide gap between how sheet-metal parts are designed in .

When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system.

0 · sheet metal parts design

1 · sheet metal manufacturability

2 · sheet metal design techniques

3 · sheet metal design skills

4 · sheet metal design principles

5 · sheet metal design guidelines

6 · sheet metal design for manufactory

7 · sheet metal design

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press , blanking, embossing .

The following are some design rules for slots and holes. Hole and slot in sheet metal design. 1. The minimum hole diameter should be ( Dmin) ≥ the thickness of the sheet metal ( at least equal to sheet thickness). 2. Proper spacing between the two holes center in a sheet .

Sheet metal design for manufacturability (DFM) is a strategic approach to part design that aligns with the intricacies of the fabrication . By incorporating best practices into your design, you can successfully create intricate shapes while maintaining manufacturability. This article focuses on key DFM best .

Mastering sheet metal design is key to achieving both precision and efficiency in manufacturing sheet metal parts. By incorporating Design for Manufacturing (DFM) principles, you can streamline production, reduce costs, and maintain high-quality standards. Whether you’re working with steel, aluminum, or copper, understanding the nuances of sheet metal processing .Get Fast Sheet Metal Quotes with Design Feedback. . Fortunately, Protolabs’ award-winning digital quoting platform reviews your model, offering 3D design for manufacturability feedback followed by real-time pricing for your prototype or low-volume production project. Users can also choose from more than 100 materials and finishes on our .

Metal sheet manufacturers spend 30% to 50% of their time fixing errors and almost 24% of those errors are related to manufacturability. The reason is usually the wide gap between how sheet-metal parts are designed in . DFM enables designers to incorporate key manufacturability factors into sheet-metal designs, minimizing errors, engineering change orders (ECOs), and bridging the gap between ideal and real-world production. . To ensure successful manufacturing of a part, engineers should adhere to the DFM specifications when creating the sheet metal design .We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. Therefore exceptions can be there for complex sheet metal parts. 7 Key Factors in Sheet Metal Design. . Here are some essential design tips for manufacturability in sheet metal fabrication: Wall Thickness. In the case of sheet metal fabrication, each component should have a uniform thickness throughout, because it is created from a single metal sheet. In general, the parts can be made in thickness from 0 .

A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. From consumer electronics, to medical devices, and obviously automotive .

A basic process establishes the starting geometry of the work material; e.g., casting, rolled sheet metal, drawn metal bar. Secondary processes are used to refine the starting geometry and transform the material into final shape and size; . It includes (1) design for manufacturability, (2) design for quality, (3) design for life cycle, and (4These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Basic Principles. . Importance of the K-factor in sheet metal design. Sheet metal design requires creating parts and assemblies from flat sheets of metal, which are then shaped or formed into desired shapes by such operations as cutting, stamping or bending. . What should you remember when using sheet metal to design a part for manufacturability? A: Optimize material usage; simplify complex geometries; ensure .

By following these design guidelines and partnering with a knowledgeable metal stamping provider, you can unlock the full potential of sheet metal stamping for your next project. Whether you need custom metal stamping dies for a complex part or guidance on optimizing your design for manufacturability, working with experts will ensure your .

For sheet metal fabricators and engineers, adhering to DFM (Design for Manufacturability) guidelines is crucial to reducing production costs and avoiding design iterations. By using 3D CAD, designers can implement DFM principles from the start, allowing for more manufacturable designs. Design for Manufacturability (DFM) is a strategic approach that integrates manufacturing considerations into the design process, ensuring that products are easier and more cost-effective to produce. When working with sheet metal, DFM is essential, especially when creating complex forms. A Comprehensive Guide for Sheet Metal Design - Sheet metal design is a specialized discipline within realm of product design and engineering. Skip to content + 91-92055-09565 | [email protected] . and ensuring manufacturability. Consider factors like material selection, bend allowances, and tolerances to create designs that are easy to .Sheet Metal Design for Manufacturability: Tips for Creating Metal-Ready Designs - Precision Sheet Metal Fabrication | Advantage Metal Products

DESIGN FOR MANUFACTURABILITY GUIDELINES Example - Sheet Metal Guidelines: Bends. Bends should be toleranced plus or minus one-half degree at a location adjacent to the bends. For the ease of manufacturing, multiple bends on the same plane should occur in the same direction. Avoid large sheet metal parts with small bent flanges.Engineering is the backbone of Tripar. We will support you through all your sheet metal fabrication needs: Design for Manufacturability (DFM), 3D CAD modelling, technical drawing creation, prototyping and sampling, and more. We produce .What I've learned about sheet metal is there are a few rules that are clear (bend radius, hole to bend distances, minimum flange widths, and deep channel limitations). However, other than that, sheet metal is wildly capable. Sheet metal guys usually just say not to worry about it, they can make it. Design for assembly ends up being more important.

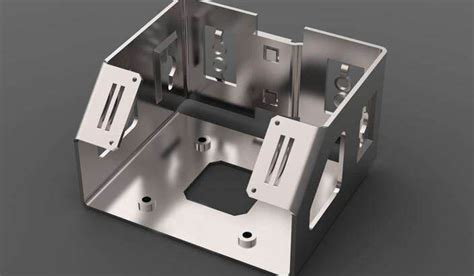

gdot junction box frame

Designing for manufacturability (DFM) is crucial when working with sheet metal to ensure cost-effectiveness, reduce lead times, and achieve the desired quality for your parts. Here are some . Design for manufacturing (DFM) is an esse nt ial aspect of product development that helps designers and engineers create simple, cost-effective products. The implementation of DFM principles means we should consider all aspects of the manufacturing process, from raw materials to final assembly, to guarantee that the product is m a d e effectively and of good .Customized product Original Equipment Manufacturer and Original Design Manufacturer, mainly for Bluetooth acoustic products and high-quality product design, plastic and sheet metal mold design, manufacturing and injection, high quality control, on-time delivery, and the fastest and best service to customers.Optimizing Part Design for Sheet Metal Fabrication. There are many design elements involved in creating parts for sheet metal fabrication—design for cost, quality, assembly, and manufacturability. Navigating that landscape can be challenging at times.

The document provides design for manufacturability guidelines for sheetmetal fabrication. It lists guidelines for minimum and maximum dimensions of various sheetmetal features such as bends, holes, notches, ribs, and more. The guidelines aim to specify dimensions that allow for ease of manufacturing while maintaining structural integrity.A knowledge-based system used for the design of sheet-metal parts is described in this paper. The system is called Sheet Metal Advisor and Rule Tutor (SMAART) and acts as an advisor to engineers designing sheet-metal parts for high volume—low . Design for Manufacturability (DFM) is a methodology aimed at designing products to streamline production, minimize costs, enhance quality, and speed up time-to-market. This article explores DFM's best practices and key considerations, equipping you with the knowledge to optimize your designs for manufacturability. . Sheet Metal Fabrication .

Sheet Metal. Experience the versatility & cost efficiency with flexible application options. Injection Molding. Production-grade steel tooling, as fast as weeks. . Design Requirements for CNC Manufacturability Learn how design requirements drive incremental manufacturing effort and how to keep effort minimized. Wednesday December 2, 2020 .following guidelines will increase the manufacturability of designs for press brake forming. . Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the . Involve us during design stage to optimize cost and performance in component design.

sheet metal parts design

Springback is a frequent challenge encountered in sheet metal bending: it occurs when a bent piece of metal partially returns to its original shape after the bending force is released. This phenomenon is a result of the material's inherent .Have you ever wondered why some sheet metal parts don’t fit perfectly after bending? This article explores the perplexing issue of springback in sheet metal processing. Learn how springback affects part accuracy and .

sheet metal design for manufacturability|sheet metal design techniques