sheet metal stamped parts We provide metal stamped parts and additional stamping solutions for all complex applications in a timeframe that promises client success. We’re able to provide short-run metal parts and . Metal–organic framework (MOF) membranes have been extensively employed for a wide range of applications. Fabrication of high-quality MOF membranes is one of the prerequisites to ensure a good performance.

0 · wholesale stamping metal parts manufacturer

1 · wholesale custom sheet metal stamping

2 · wholesale custom metal stamping parts

3 · metal stamping process step by

4 · metal stamping process flow chart

5 · high quality stamping metal parts

6 · high quality metal stamping manufacturers

7 · customized metal stamping part factory

If it's aluminium/plastic soffit covers, you'll have to remove the section where you're installing the receptacle. Install proper bracing (a simple 2x4 between the rafters should be fine), and attach the electrical box to it.

We provide metal stamped parts and additional stamping solutions for all complex applications in a timeframe that promises client success. We’re able to provide short-run metal parts and .CUSTOM STAINLESS STEEL STAMPING. Winco Stamping is America’s trusted .Aluminum stamped parts are often used for mounting computer systems and internal .Custom Hot Rolled Steel Stamped Parts. Winco Stamping provides custom hot .

Custom Copper Stamped Parts. Winco Stamping provides short run and .Standard Die International is a full-service precision metal stamping & deep drawn parts company for a growing list of industries. Get a free quote today! (800) 838-5464Xometry offers custom metal stamping services in a range of materials, including aluminum and copper. Get an online metal stampings quote for high-quality parts today. Fabricating sheet metal stamping parts is simple and straightforward with the right information. Whether you want to choose suitable material, adopt the best technique, or equipment – everything you’re looking .

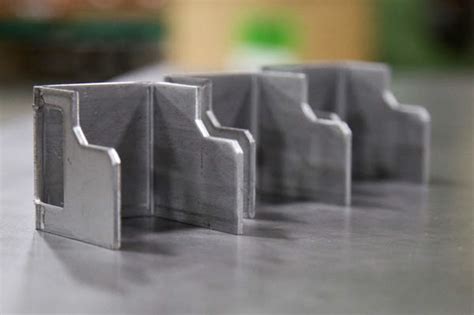

Sheet metal stamping involves using dies and stamping presses to shape flat metal sheets into specific designs. In this process, pressure is applied to cut, bend, or form the sheet into the .We create a range of metal components in all sizes, from simple to intricate. We provide service and support to our customers throughout the entire process, from prototype development through high-volume production. We have the . Metal stamping is a common manufacturing process used to create a variety of precision metal parts by shaping and cutting sheet metal using a press and die. This process is widely used in various applications in the .The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by applying an external force. Stamping machines and dies are used to achieve this. It’s fascinating. Seeing a simple .

Sheet metal stamping is the process of turning sheets of metal into useful parts or components. What kind of sheet metal options are available to be metal stamped? At Atlantic Precision Spring we offer steel, stainless steel, brass, .Sheet small metal stamping produces superior, resilient, heavy-duty parts quickly and efficiently. We guarantee every metal stamping hardware parts are precise, they're typically more reliable and consistent than manual machining. Our .There are a number of factors to consider when designing stamped metal parts with holes to ensure proper manufacturing and functionality. Hole Diameter The minimum diameter of any hole should be 1.2x the material thickness . Burr allowance is generally 10% of the thickness of the sheet material. To minimize instances and severity of burrs .

Metal stamping is the manufacturing process in which a strip of sheet metal is fed through one or more die and tool sets to apply pressure, re-forming and cutting the piece into a desired shape. The sheet metal can come in either blank or .

wholesale stamping metal parts manufacturer

What Is Sheet Metal Stamping? Sheet Metal Stamping Process. There are basically only three components to sheet metal stamping—the sheet metal, die, and press machine—but any single part can require multiple steps to arrive at its final form. The following guide explains a few common processes that might occur during metal stamping. Forming .Xometry offers a wide variety of production volumes for sheet metal stamping, including: . High volume production includes orders of over 1 million parts. While metal stamping is very scalable, it’s an incredibly cost-effective manufacturing process for high volumes, as this drives down unit costs stemming from the price of creating custom .Our diverse range of automatic stamping machines with press forces from 25 t to 250 t is capable of handling different grades of steel, carbon steel, stainless steel, aluminium and non-ferrous metal alloys in thicknesses from 0.15 to 4 mm. Our experienced workforce produces high-precision punched, bent and drawn parts on these machines.

The metal stamping process also creates parts with various finishes and coatings, which can enhance the appearance, durability and functionality of the final product. . The sheet metal stamping process typically involves several key steps, each contributing to creating a high-quality metal component. Design and Die Creation.TMK Makina has been active in sheet metal stamping and metal forming services in Turkey since 2006, with customers in Turkey and Abroad.. Skip to content. Company. About Us; Quality; . Metal Stamping Parts. We are serving our customers for their large parts fabrication needs.. Know more about our expertise in sheet metal stamping .Our Sheet metal stamping parts manufacturing service includes: Stamping Dies Design; Testing and manufacturing sample parts; Serial Production of Parts; Secondary operations like coating and assembly with our sub-contractors (In case needed) Delivery; Our advantages in Sheet metal stamping parts manufacturing service..China Stamping Parts Manufacturer. China Stamping Parts is a professional metal stamping company that specializes in CNC Punching, Deep Drawing, High Speed Stamping, Sheet Metal Stamping for various industries, we also provide the secondary operations and assembly of metal parts like riveting, welding, plating and so on.

Custom metal stamping manufacturer producing millions of steel, stainless, and aluminum parts annually, offering high-volume, low-cost solutions. . HSLA, Steel, copper, and other metals demands precision. Our ISO 9001 registered quality system assures you defect-free stamped metal parts with the tolerances you need and at high volume .Nirvaan Global stands as a beacon of excellence in the world of metal stamping. As your trusted partner, we invite you to explore the vast array of solutions we offer, ranging from metal stamping parts and steel stamping parts to sheet metal products and metal deep drawing. Experience precision, reliability, and innovation – experience . Hi all, Does the Fusion 360 sheet metal workspace have tools for created impressed/formed sheet metal parts? For example, if I wanted to press in some text on a sheet metal part. I can do a simple extrude and filet but this does not cause the metal to come out on the other side. How do I create so that if I send the file to a manufacturer they will know to only .Large Metal Stamping Parts; Machined Parts; mainly for following industries: Home Appliances; Automotive; Our company was founded in 2006, have a factory with closed area of 1.100 sqm, located in Gebze, near Istanbul. We serve Turkey’s largest corporations for their needs of large size stamping dies & Tools, Serial production of large .

Using custom-made stamping dies and precision stamping equipment, sheet metal is cut or formed into a desired shape. From complex parts to simple components, Tempco is ready to deliver uncompromising results paired with .Stamped parts were used for mass-produced bicycles in the 1880s. Stamping replaced die forging and machining, resulting in greatly reduced cost. . Sheet metal forming simulation is a technology that calculates the process of sheet metal stamping, [7] [8] predicting common defects such as splits, wrinkles, springback and material thinning.We Provide the best quality industrial sheet metal stamped parts world wide. More than just being a metal fabricating company, Priyank Engineering partner with customers, providing innovative and cost effective products that achieve competitive and strategic market advantages for .

wholesale custom sheet metal stamping

Aluminum Metal Stamped Parts. Stamping aluminum parts is popular due to their numerous benefits such as: Excellent surface finish – stamped aluminum parts have a good surface finish. . Generally, aluminum has desirable mechanical, physical, and chemical properties for most sheet metal stamping applications.Valiant Precision Sdn. Bhd. established in year 2002. We are ISO 9001:2015 Quality Management System Certified. We manufacture precision parts in metal stamping, sheet metals fabrication, multi-forming, Wire netting, tools and dies for industries such as Air-Conditioning, Electrical & Electronic, Automotive, Telecommunication, Furniture, Construction, Hardware, Engineering .Standard Die International is a full-service precision metal stamping & deep drawn parts company for a growing list of industries. Get a free quote today! (800) 838-5464 Partner with trusted Sheet Metal and Stamped parts suppliers to achieve precision-engineered components for a variety of industries. Secondary Operations. After blanking, some projects may require additional steps known as secondary operations. These may include deburring—smoothing out sharp edges—as well as surface finishing techniques .

Sheet Metal Stamping Parts was the first product category Source International (SI) worked with the OEM customer. The customer needed hundreds of different parts with size ranging from 0.5” to 120”, and a great variety of finish (powder coating, zinc plating, nickel plating, black oxide, etc.). The precision of the parts was of the essence .

Our facilities leverage various presses from 30 to 400-ton capacity to produce a wide range of custom metal stamping parts. The metallurgical expertise we use to design our spring and fastener products also extends to stampings, allowing our engineers to create components utilizing materials from low-carbon steel to pre-tempered alloys in thicknesses from .004″ to .

need to minimize sheet metal scrap generation in order to reduce environmental impacts. INTRODUCTION Sheet metal stamping is used to form three-dimensional parts from flat sheet metal shapes known as ‘blanks’. It is widely used in the car industry to form inner and outer body

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. To achieve the required sheet metal tolerance in sheet metal part design guidelines, manufacturers must use precise machinery during production.Metal stamping is a manufacturing technique used to create high-precision, high-volume parts from sheet metal or metal coils. This process involves the use of specialized machinery and dies (tools) to deform, shape, cut, or pierce metal sheets or coils into the desired shapes and sizes.In our custom sheet metal stamping process from coils, we manufacture from low to high-volume stamped parts using progressive die stamping technology. This process enables us to stamp, bend, and cut threads, making it highly competitive and efficient for producing stamped and deep-drawn sheet metal components.

wholesale custom metal stamping parts

metal stamping process step by

Typical coverplate screws are 6-32. Answers based on the National Electrical Code. Local amendments may apply. Check with your local building officials. If the box is a round type, as commonly used for ceiling lights, then an 8-32 screw would be appropriate.

sheet metal stamped parts|high quality stamping metal parts