canning process sheet metal Oil Canning can be defined as visible waviness in the flat areas of metal roofing and metal wall panels. In technical terms, oil canning is referred to as elastic buckling (more commonly known .

Color Design Guide – A comprehensive overview of modern color trends and finish options for metal roofs and walls. Metal Wall Design Guide – Designed to enlighten building designers as to the shape and color possibilities available with single skin metal wall panels.

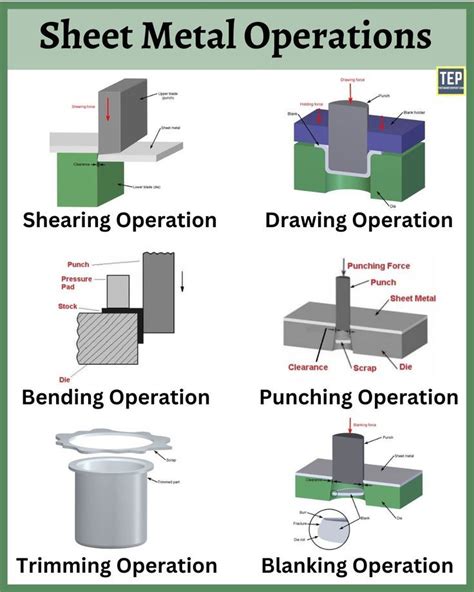

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal process in manufacturing

4 · sheet metal fabrication techniques

5 · sheet metal diagram fabrication

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

Versatile, durable and affordable, the steel kits from Arched Cabins can be used for workshops, tiny homes, offices, vacation homes, hunting lodges, granny pods and more. Build it yourself, or use Arched Cabins’ team of builders to construct the shell of the structure for you.

Oil Canning can be defined as a perceived waviness in the flat areas of metal roofing and metal siding panels. Generally the period and amplitude of the wave depend on the continu-ous .

Oil canning is a moderate deformation or buckling of sheet material, particularly common with flat sheet metal surfaces. It is seen as waviness in the flat areas of the metal roof or wall material. This phenomenon .Oil canning can be defined as the perceived waviness of a metal panel and is an inherent characteristic of light-gauge, cold-rolled flat metal products. This waviness generally depends on the continuous width of the flat, and metal . Oil canning in metal is an observed waviness or buckling across the flat areas of sheet metal panels that does not normally affect the roof's structural integrity. Metal Construction News asked five industry experts to .“Oil Canning” in metal roofing and/or siding is a common, yet natural occurrence that happens in light sheet metal products, which include but are not limited to, steel, copper, zinc & aluminum. .

Oil Canning can be defined as visible waviness in the flat areas of metal roofing and metal wall panels. In technical terms, oil canning is referred to as elastic buckling (more commonly known . Two Simple Strategies You Can Apply in AutoForm to Improve Oil Canning on Sheet Surfaces In this blog post Curtis Hsiung, Application Engineer from AutoForm USA, reveals how to handle the excess bulging or buckling of .

Oil Canning can be defined as visible waviness in the flat areas of metal roofing and metal wall panels. In technical terms, oil canning is referred to as elastic buckling (more commonly known .Oil canning is a characteristic of thin gauge cold formed metal products defined as moderate deformation or buckling of sheet material, particularly common with flat sheet metal surfaces. Typically caused by uneven stresses at the fastening .

Oil canning is a visual phenomenon that can occur with standing seam metal roof and wall panel systems. Discover why oil canning occurs, what to look for during installation, and how to minimize the chance of it happening.

Oil Canning can be defined as a perceived waviness in the flat areas of metal roofing and metal siding panels. Generally the period and amplitude of the wave depend on the continu-ous width of the flat. Oil canning is an inherent part of light gauge cold formed metal products, particularly those with broad flat areas. Oil canning is a moderate deformation or buckling of sheet material, particularly common with flat sheet metal surfaces. It is seen as waviness in the flat areas of the metal roof or wall material. This phenomenon will seem very apparent at times and seem to disappear at others due to the angle of the sunlight.Oil canning can be defined as the perceived waviness of a metal panel and is an inherent characteristic of light-gauge, cold-rolled flat metal products. This waviness generally depends on the continuous width of the flat, and metal profiles which have wide flat surfaces, or more commonly referred to as “architectural” roofing and siding .

Oil canning in metal is an observed waviness or buckling across the flat areas of sheet metal panels that does not normally affect the roof's structural integrity. Metal Construction News asked five industry experts to describe in their own words its impact and remedy.“Oil Canning” in metal roofing and/or siding is a common, yet natural occurrence that happens in light sheet metal products, which include but are not limited to, steel, copper, zinc & aluminum. “Oil Canning” creates a unique perceived waviness, elastic buckling or stress wrinkling in the flat portion of the metal roofing and/or siding panels.Oil Canning can be defined as visible waviness in the flat areas of metal roofing and metal wall panels. In technical terms, oil canning is referred to as elastic buckling (more commonly known as “stress wrinkling”). Oil canning can occur in any type of . Two Simple Strategies You Can Apply in AutoForm to Improve Oil Canning on Sheet Surfaces In this blog post Curtis Hsiung, Application Engineer from AutoForm USA, reveals how to handle the excess bulging or buckling of a sheet metal surface, better known as the problematic “Oil Canning” effect.

Oil Canning can be defined as visible waviness in the flat areas of metal roofing and metal wall panels. In technical terms, oil canning is referred to as elastic buckling (more commonly known as “stress wrinkling”). It can occur in any type of metal panels: steel, aluminum, zinc, or copper.Oil canning is a characteristic of thin gauge cold formed metal products defined as moderate deformation or buckling of sheet material, particularly common with flat sheet metal surfaces. Typically caused by uneven stresses at the fastening points. Oil canning is a visual phenomenon that can occur with standing seam metal roof and wall panel systems. Discover why oil canning occurs, what to look for during installation, and how to minimize the chance of it happening.Oil Canning can be defined as a perceived waviness in the flat areas of metal roofing and metal siding panels. Generally the period and amplitude of the wave depend on the continu-ous width of the flat. Oil canning is an inherent part of light gauge cold formed metal products, particularly those with broad flat areas.

Oil canning is a moderate deformation or buckling of sheet material, particularly common with flat sheet metal surfaces. It is seen as waviness in the flat areas of the metal roof or wall material. This phenomenon will seem very apparent at times and seem to disappear at others due to the angle of the sunlight.Oil canning can be defined as the perceived waviness of a metal panel and is an inherent characteristic of light-gauge, cold-rolled flat metal products. This waviness generally depends on the continuous width of the flat, and metal profiles which have wide flat surfaces, or more commonly referred to as “architectural” roofing and siding .

Oil canning in metal is an observed waviness or buckling across the flat areas of sheet metal panels that does not normally affect the roof's structural integrity. Metal Construction News asked five industry experts to describe in their own words its impact and remedy.“Oil Canning” in metal roofing and/or siding is a common, yet natural occurrence that happens in light sheet metal products, which include but are not limited to, steel, copper, zinc & aluminum. “Oil Canning” creates a unique perceived waviness, elastic buckling or stress wrinkling in the flat portion of the metal roofing and/or siding panels.Oil Canning can be defined as visible waviness in the flat areas of metal roofing and metal wall panels. In technical terms, oil canning is referred to as elastic buckling (more commonly known as “stress wrinkling”). Oil canning can occur in any type of . Two Simple Strategies You Can Apply in AutoForm to Improve Oil Canning on Sheet Surfaces In this blog post Curtis Hsiung, Application Engineer from AutoForm USA, reveals how to handle the excess bulging or buckling of a sheet metal surface, better known as the problematic “Oil Canning” effect.

Oil Canning can be defined as visible waviness in the flat areas of metal roofing and metal wall panels. In technical terms, oil canning is referred to as elastic buckling (more commonly known as “stress wrinkling”). It can occur in any type of metal panels: steel, aluminum, zinc, or copper.

various sheet metal processes

steel box beams for sale

a white farmhouse with metal roof. image © stephaniegambleinteriors.com. Are you looking for a roof and house combination that is perfect for a hot climate? If so, this option that we will discuss is an excellent choice you must consider. It is a white house with a chrome-color metal roof.

canning process sheet metal|various sheet metal processes