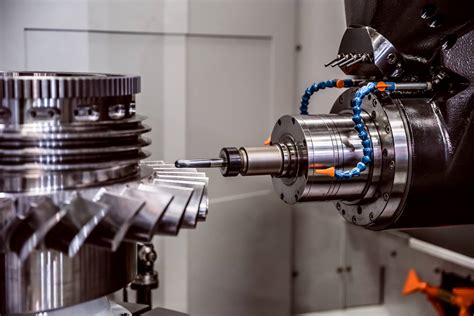

aircraft cnc machine parts What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, . Yes, you can glue fabric to metal. Using the right adhesive and proper application techniques, it’s possible to create a strong bond between fabric and metal surfaces. The process involves preparing the metal surface by cleaning and, if needed, roughening it for better adhesion.

0 · what is aerospace cnc machining

1 · cnc aircraft type

2 · cnc aerospace parts

3 · aircraft cnc machining

4 · aerospace manufacturing cnc machining

5 · aerospace connector manufacturing machine

6 · aerospace cnc machining services

7 · aerospace cnc machine shop

What size of drill bit do I use for a #8 screw in metal? The recommended drill bit size to use for a #8 screw in metal is 1/ 16" to 3/16" for small twist bits. But, for larger twist bits, I suggest using 11/ 16" to 1" drill bit.

With our ultra-precise CNC machines, your aircraft will be more efficient and affordable than ever. We can create customizable parts to ensure a better fit for your aircraft designs. Our 5-axis machines allow for multiple part components . What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, . What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft.With our ultra-precise CNC machines, your aircraft will be more efficient and affordable than ever. We can create customizable parts to ensure a better fit for your aircraft designs. Our 5-axis machines allow for multiple part components to be made .

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.Ardel Engineering & Manufacturing works with some of the world's leading aircraft and aerospace companies. Aerospace manufacturers use CNC machining to assemble and maintain essential aircraft and space shuttle components.

Aerospace CNC machining is the creation of parts used in assembling and maintaining rockets, satellites, aircraft and space shuttles. CNC-machined components, kits and assemblies are often necessary for aircraft in the aerospace industry.With accuracy to a few micrometers and a minuscule margin for error, CNC machines produce parts that fit accurately into aircraft, preventing general part failure and consequential loss of property. Lastly, CNC machining enhances efficiency in the aerospace industry.To build the best rocket ships, NASA and SpaceX use CNC machining to manufacture tiny parts that tether the rocket’s body design. These parts must operate without fail and prioritize the safety of the spacecraft and its crew members.CNC machining plays a crucial role in creating intricate and complex aircraft components such as engine parts, landing gear, and structural elements. The precision and accuracy of CNC machines enable the production of intricate designs that are vital for the performance and safety of aircraft.

From creating the small, connected modules that form the navigational system to machining large fuel bodies, transmissions and landing gear, passenger planes, helicopters, fighter jets and cargo planes all rely on CNC milling for the precision production of state-of-the-art aircraft components.Contact Owens for aircraft part manufacturing. Aircraft companies looking for reliable a partner to precision machine their complex components can rely on Owens Industries. Contact today to receive a quote. What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft.With our ultra-precise CNC machines, your aircraft will be more efficient and affordable than ever. We can create customizable parts to ensure a better fit for your aircraft designs. Our 5-axis machines allow for multiple part components to be made .

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.

what is aerospace cnc machining

cnc aircraft type

Ardel Engineering & Manufacturing works with some of the world's leading aircraft and aerospace companies. Aerospace manufacturers use CNC machining to assemble and maintain essential aircraft and space shuttle components.Aerospace CNC machining is the creation of parts used in assembling and maintaining rockets, satellites, aircraft and space shuttles. CNC-machined components, kits and assemblies are often necessary for aircraft in the aerospace industry.

With accuracy to a few micrometers and a minuscule margin for error, CNC machines produce parts that fit accurately into aircraft, preventing general part failure and consequential loss of property. Lastly, CNC machining enhances efficiency in the aerospace industry.

To build the best rocket ships, NASA and SpaceX use CNC machining to manufacture tiny parts that tether the rocket’s body design. These parts must operate without fail and prioritize the safety of the spacecraft and its crew members.CNC machining plays a crucial role in creating intricate and complex aircraft components such as engine parts, landing gear, and structural elements. The precision and accuracy of CNC machines enable the production of intricate designs that are vital for the performance and safety of aircraft.From creating the small, connected modules that form the navigational system to machining large fuel bodies, transmissions and landing gear, passenger planes, helicopters, fighter jets and cargo planes all rely on CNC milling for the precision production of state-of-the-art aircraft components.

cnc aerospace parts

wood cnc router machine price

Attach the mounting bracket: Attach the bracket to the studs using screws designed for metal framing. Check the stability: Double-check the stability of the mounting bracket by applying pressure and ensuring it is securely fastened to the metal studs.

aircraft cnc machine parts|cnc aircraft type