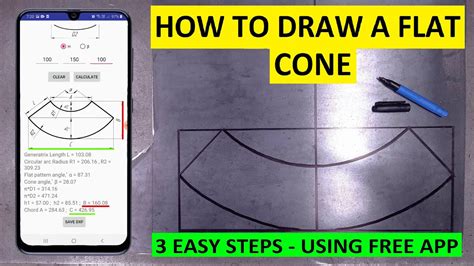

developing a cone in sheet metal How to develop a cone or how to create a flat pattern of a cone can be achieved in a few easy geometrical steps. The geometrical method shown below does however have inaccuracy, so at the end of this article I have .

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

0 · truncated cone from flat sheet

1 · sheet metal transition layout

2 · sheet metal cone rolling calculation

3 · sheet metal cone formula

4 · sheet metal cone fabrication

5 · creating a cone layout

6 · cone sheet metal calculator

7 · cone layout formula

$295.00

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number of gore sections to fit on . Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with .Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone. Locate a radius point where you want to develop the pattern.

truncated cone from flat sheet

sheet metal transition layout

The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height . How to develop a cone or how to create a flat pattern of a cone can be achieved in a few easy geometrical steps. The geometrical method shown below does however have inaccuracy, so at the end of this article I have .

A cone which has its axis non-perpendicular to its base is known as an oblique or scalene cone. Referring to the diagram above, in order to produce its development we need to find the lengths of the lines from the vertex V to a set .

What's important to remember with radial line development is all tapers (slants) must remain constant. (Left). First step, draw an elevation view of the cone (this can be any measurements) for this tutorial we used 12" as a .

Calculates the measurements for the pattern to construct a flat top cone.Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number .So, in this post, we are covering all the Points related to Full Cone Layout Development so that you can learn in-depth and used this method in daily fabrication activity.

Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.

Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with Knuckle Radius at .Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone. Locate a radius point where you want to develop the pattern.The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height of the cone. How to develop a cone or how to create a flat pattern of a cone can be achieved in a few easy geometrical steps. The geometrical method shown below does however have inaccuracy, so at the end of this article I have included a mathematical formula to help produce an accurate conical development.

A cone which has its axis non-perpendicular to its base is known as an oblique or scalene cone. Referring to the diagram above, in order to produce its development we need to find the lengths of the lines from the vertex V to a set of equally spaced points around the circular base. What's important to remember with radial line development is all tapers (slants) must remain constant. (Left). First step, draw an elevation view of the cone (this can be any measurements) for this tutorial we used 12" as a base and 5" as a top dia.Calculates the measurements for the pattern to construct a flat top cone.

sheet metal cone rolling calculation

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number .

So, in this post, we are covering all the Points related to Full Cone Layout Development so that you can learn in-depth and used this method in daily fabrication activity. Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.

Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with Knuckle Radius at .

Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone. Locate a radius point where you want to develop the pattern.The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height of the cone. How to develop a cone or how to create a flat pattern of a cone can be achieved in a few easy geometrical steps. The geometrical method shown below does however have inaccuracy, so at the end of this article I have included a mathematical formula to help produce an accurate conical development.A cone which has its axis non-perpendicular to its base is known as an oblique or scalene cone. Referring to the diagram above, in order to produce its development we need to find the lengths of the lines from the vertex V to a set of equally spaced points around the circular base.

What's important to remember with radial line development is all tapers (slants) must remain constant. (Left). First step, draw an elevation view of the cone (this can be any measurements) for this tutorial we used 12" as a base and 5" as a top dia.

To weld thin stock successfully, use a small diameter tungsten electrode like 0.020, 0.040, and 1/16 in. Large-diameter tungsten electrodes require higher amperage to start the arc, leading to warping or burning of the material. Grind the tungsten tip to a sharp point to weld steel, and use either ER70S-2 filler metal or a silicon bronze rod.

developing a cone in sheet metal|sheet metal cone rolling calculation