solidworks sheet metal rolled cylinder How to Prepare Rolled Sheet Metal Parts in SolidWorks. Let’s walk through the steps necessary to flatten a rolled sheet metal part in Solidworks to prepare it for laser cutting. Step 1: Use “Cut-Extrude” to make a parting line in .

You could install a shallow "pancake" electrical box on the wall and then the wire would be within the box. (e.g. https://www.lowes.com/pd/RACO-1-Gang-Gray-Metal-New-Work-Shallow-Ceiling-Pans-Ceiling-Electrical-Box/1099827 )

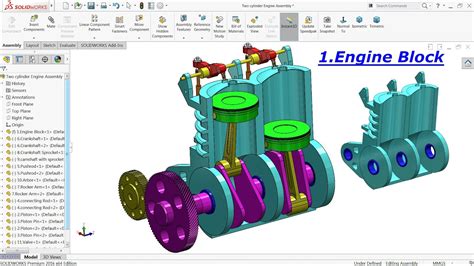

0 · solidworks training cylinder design

1 · solidworks sheet metal curved bend

2 · solidworks rolled sheet metal

3 · solidworks flatten cone

4 · solidworks conical sheet metal

5 · sheet metal cone in solidworks

6 · making a cone in solidworks

7 · flatten a cylinder in solidworks

Yellow box junctions: what you need to know. What is the point of a yellow box junction? A box junction keeps traffic flowing by marking out an area of road space that.

Parts with cylindrical faces can be made of sheet metal if they meet the following criteria: Any adjacent planar and cylindrical faces must be tangent. At least one end face of any cylindrical .

In this video, I’ll show you how to use the Insert Bends command to tackle three common use cases for designing and flattening a rolled cylinder or cone in SOLIDWORKS Sheet Metal. This video explores two methods for creating sheet metal cylinders.

yes! Create a circle profile with a very small gap, and then make a base tab, this will extrude to your selected length and material thickness. I have a Sheetmetal part, that I am designing, flat . E23 SolidWorks 2012 - Cylindrical Sheet Metal. vertanux1. 63.8K subscribers. 388. 78K views 11 years ago. Exercise 23 - Cylindrical Sheet Metal parts, Linear sketch patterns .more..

How to Prepare Rolled Sheet Metal Parts in SolidWorks. Let’s walk through the steps necessary to flatten a rolled sheet metal part in Solidworks to prepare it for laser cutting. Step 1: Use “Cut-Extrude” to make a parting line in .Hi! ( Noobie here) I would like to Basic Motion (Motion Study) a flat metal sheet to roll around a cylinder which is fixed on a stand (Eg. GIF attached). Can someone please guide me with a .Learn how annotations are assigned to views, best practices for making cuts on rolled sheet metal cylinders, and how to modify features to support the Model Items command. In this video, we’ll show you how to use the Insert Bends command to tackle three common use cases for designing and flattening a cone or rolled cylinder in SOLIDWORKS Sheet Metal.

Learn how to create a SOLIDWORKS rolled component using sheet metal tools so you will be able to unroll/flatten the component if required.

Exercise 23 - Cylindrical Sheet Metal parts, Linear sketch patterns How to create a simple rolled sheetmetal partHi! ( Noobie here) I would like to Basic Motion (Motion Study) a flat metal sheet to roll around a cylinder which is fixed on a stand (Eg. GIF attached). Can someone please guide me with a video tutorial or step by step procedure of how to achieve this effect. I'm using Solidworks 2015 (SP5) Thanks in Advance!

Sheet metal cylinder with overlap for welding. There is also shroud on bottom end and swage roll in the middle. How to? . ©2002-2024 Dassault Systemes SolidWorks Corporation .

Within SW there a multiple ways to achieve a rolled cylinder both starting from the flat and rolling or creating the cylinder and flattening. . To do it in solidworks sketch an open circle with gap 1-1.5 mm. Use circular dim to make length 2000 then make sheet metal part. Note as mentioned the 2000 is the neutral axis of the sheet. A recent customer query had us considering a number of different methods to create a roll of material. After a number of attempts using various methods, the following suggestion was to create a SOLIDWORKS rolled component using the sheet metal functionality, this technique came from technical sales manager Elton Smith at DS SOLIDWORKS.The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Hey everyone, I'm kinda stumped on how to make these stamped indentations which have cuts on the inside (Note this stamped sheet metal rolled into a cylinder - for a hydraulic filter). . (Note this stamped sheet metal rolled into a cylinder - for a hydraulic .The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Hi, Could anyone help me with following scenario: I have a rolled cylinder (359.9°), which is originated from Solid Edge. . Feature recognition: imported sheet metal (rolled cylinder) MS By Markku Sutinen 04/29/15. Hi,

Good Morning Everyone, I'm trying to convert a mitered pipe segment piece into a sheet metal part that can be flattened then plasma-cut and rolled. The shop drawing calls for small sections of pipe to be cut width-wise then mitered both ways (see attachment). In this video, I am going to explain about, How to Develop the Blank Flat Length for a Cylinder Sheet. Here, I am going to explain, how to calculate "Blank F. The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. . and draw a cylinder made from sheet metal. The holes in the side of the cylinder are made in the "Flat" state however they are driven by the angle that they need to be in the rolled state. I could make a 3d hole however there are 2 problems 1. the actual hole .

metal fabrication in kent

In this video, I am going to explain about how to create Rolled Sheet Metal & Tubes.I am to explain in detail about below topics,1. Rolled Sheet Metal2. Shee. I tried using base flange under sheet metal to get the rolled piece, then create a new sketch to layout the hole locations. I was hoping if I put sketch points on the rolled piece, then flattened it, that the sketch points would transfer to the piece in the flat, and therefore allow me to sketch circles and extrude cut, then roll back up.Depends on the design and application. You can try and convert the part to sheet metal or if the design is a sketch you could make the cylinder first, put the sketch normal and tangent to the cylinder and then project onto the rounded surface.The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. I have a cylinder which has been rolled in sheet metal which is from a pressure vessel (Industrial Boiler). If I then extrude cut a circular hole which is offset from the centre-line, I find that the cut in the cylinder is incorrect and is closer to a "figure of 8

The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. I am trying to make a clamshell cylinder with two edge flanges on the seams with rivet holes. . I do want the mating faces of the edge flanges vertically aligned and on the centerline of the sheet metal rolled cylinder's axis. answers: 22.Hi I have a cylinder with a series of fittings in it. I want a flat plate with all the holes already in the cylinder, so it can be sent for rolling and when finished all the holes are in the correct place. I made a sheet metal cylinder/ barrel drawn with centre point arc, and made into sheet metal as base flange I then place the barrel in .Need to know if this is possible - see attached. Want to create a weld between the gaps, I'm Currently running SW2014. Im trying to create a sheet metal tube with an endcap on it. to draw the tube i followed the tutorial found on youtube: Rolled Sheet Metal - SOLIDWORKS 2014 - .

In this video, I am going to explain about creating "Overlapping Cylindrical Sheet" in Solidworks-Sheet Metal.-----.I have to wrap that cylinder with sheet metal as in attached file and also have to match the holes on rolled sheet metal to the holes on cylinder. if I make holes on flat pattern at equal distance, it won't match to the holes on cylinder. if I make holes on .Parts with cylindrical faces can be made of sheet metal if they meet the following criteria: . The cylinder is now a sheet metal part. . Version: SOLIDWORKS 2020 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > .

I have been attempting to make a curved sheet metal circular part.not working. Any suggestions would be helpful. The closest I can get is to make an accurate half, then mirror the part, create assembly but when flattened falls apart. Sheet Metal Part: Diameter 22" x 0.1345 (10GA.) thick. Part will be rolled/curved on a 48.1875" cylinder. In this video, I'll show you how to use the Insert Bends command to design and flatten cone or rolled cylinder in SOLIDWORKS Sheet Metal. With over 35 years of experience, the TriMech Group offers a comprehensive range of design, engineering, staffing and manufacturing solutions backed by experience and expertise that is unrivalled in the industry.I can't seem to convert this part into sheet metal. from what I'm understanding Solidworks is having trouble how to interpret the cylindrical part and the half-cylinder part into sheet metal. . this part can not be manufactured out of a single sheet. tube like the bottom part aren't bend with a press but rolled. Top part are way too long .The sheet metal-specific features make it easier and faster to create a sheet metal part than designing a part, then converting it to sheet metal. SOLIDWORKS includes sheet metal-specific features so you can create a part as sheet metal without having to convert it to sheet metal.

Actually, I was just informed that, when they construct a cylinder, they will roll the steel to where the 2 ends almost meet, leaving the 2 ends 1/8" apart from each other, to allow for welding. So, I guess, until someone shows me a better way to create a cylinder, this way will have to do. . SolidWorks ; Sheet Metal Cylinder - "Creating . I used the extrude / thin feature to create the rolled cylinder with overlapping. Maybe this is causing the issue. I drew a 3 point arc then another arc for the overlapped portion at approx. 90 degrees. I didn't apply any sheet metal features yet for flattening since there is an issue with the letters. I'm attaching the .sldprt for reference.

solidworks training cylinder design

However, when it comes to placing a junction box in a closet, several factors need to be considered to ensure compliance with safety regulations. In this article, we will explore .

solidworks sheet metal rolled cylinder|solidworks rolled sheet metal