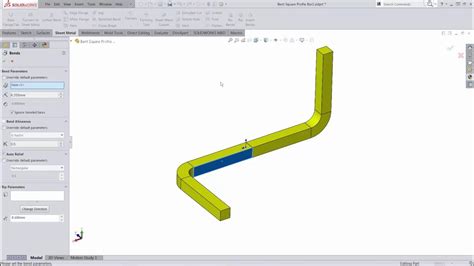

insert a bend on sheet metal parts in solidworks In this video i show you how Use Insert Bends in Solidworks.I hope this video will help you to design use Solidworks.Just enjoy it, and like it.Thanks For Wa. The main products have obtained ATEX EU explosion-proof certification and IECEx international explosion-proof certification. CZ has agents or offices in 28 countries and regions, and .

0 · solidworks unbend sheet metal

1 · solidworks sketched bend

2 · solidworks sheet metal sketched bend

3 · solidworks sheet metal round bend

4 · solidworks sheet metal bend relief

5 · solidworks bend notes not showing

6 · sketch must have disjoint lines

7 · how to use sketched bend

Ningbo Dowell Technology Co., Ltd. is a reputable manufacturer, supplier, and factory located in China, well-known for designing and producing top-notch outdoor fiber distribution boxes. Our .

It is possible to create a solid part, then convert it to sheet metal to add the bends and sheet metal features. When you click Insert Bends on the Sheet Metal toolbar, or click Insert > Sheet Metal > Bends, two distinct stages are applied to the sheet metal part.When designing sheet metal parts, the order preference for use of feature tools .To create a sheet metal part with round bends: Sketch a closed or open profile. .Insert bends allows you to convert a shelled part to a sheet metal part. Requirements include: Solid body. Uniform thickness. Thin feature. Alternatively, you can create a part directly out of .

solidworks unbend sheet metal

solidworks sketched bend

In this video i show you how Use Insert Bends in Solidworks.I hope this video will help you to design use Solidworks.Just enjoy it, and like it.Thanks For Wa.When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the .

It is possible to create a solid part, then convert it to sheet metal to add the bends and sheet metal features. Sheet Metal Features. When you click Insert Bends on the Sheet Metal toolbar, or .

Solidworks - Sheet Metal - "Insert bends" tutorial with working files and video. If you cannot view the flv video file, then download and install VLC media player located here.

In SOLIDWORKS, a Sheet Metal Sketched Bend is a method of adding a bend to a sheet metal part relative to a line in a special sketch. This special sketch is created within the Sketched Bend command. Initiating a base feature like the Extruded Boss/Base - we will show you how to set up a Sheet Metal part using the Base Flange/Tab feature instead which will concurrently set up your basic.To add a body to a sheet metal part using Insert Bends: In a sheet metal part, select or create a plane and draw a profile sketch. Click Extruded Boss/Base (Features toolbar). Set the .

To create a sheet metal part with round bends: Sketch a closed or open profile. Create a thin feature part. Depending on the type of profile, you can use tools such as Shell or Extruded Boss/Base to create thin features. Click Insert .

Insert Bends: Bends PropertyManager: Adding Sheet Metal Gussets : Sheet Metal Tabs: Tab and Slot : . A rip feature is commonly used to create sheet metal parts, but you can add a rip feature to any part. . you can flatten the .You can create a multibody sheet metal part by creating new sheet metal parts within an existing sheet metal part. You can add new sheet metal bodies using these commands: Base Flange/Tab; Convert to Sheet Metal; Insert Bends; Lofted-Bend; For all commands, . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and .As a test, try to insert an axis on the conical face. If you can insert an axis, the model is an exact cone. If you cannot insert an axis, then the model is not an exact cone and cannot be unfolded. However, sheet metal parts created with .Sheet-Metal1: Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Sheet-Metal is stored in the Sheet-Metal folder. Flatten-Bends1: Flatten-Bends represents the flattened part .

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .When creating sheet metal parts, the order of design preference is: Sheet metal features (such as Base Flange, Edge Flange, and Miter Flange); Insert Bends feature; Convert to Sheet Metal feature; When using the Insert Bends and Convert to Sheet Metal features, it is best to apply them as early as possible during part design, preferably right after you create the first non-sheet .Using Sheet Metal Bend Parameters: Simulation: SimulationXpress: Sketching: SLDXML Data Exchange: . Splines are invalid sketch entities for sheet metal parts with open contours. Click Base-Flange/Tab or Insert > Sheet Metal > Base Flange. The Base Flange PropertyManager appears. Under Direction 1:

solidworks sheet metal sketched bend

Multibody Sheet Metal Parts: Using Sheet Metal Bend Parameters: Simulation: SimulationXpress: Sketching: . Troubleshooting: Legal Notices: Insert Bends. Insert bends allows you to convert a shelled part to a sheet metal part. Requirements include: Solid body; Uniform thickness; Thin feature; . Search 'Insert Bends' in the SOLIDWORKS .

Select a linear edge of a planar face on the model to attach the wall to, and click Convert Entities on the Sketch toolbar, or click Tools > Sketch Tools > Convert Entities.; Click .; Drag the vertices near existing bends a small distance away from the bends to allow for the bend radius.In the Insert Part PropertyManager:. Under Transfer, select Sheet metal information if you want to transfer the sheet metal and flat pattern information from the original part to the mirrored part, such as fixed face, grain direction, bend lines, and bounding box. You can also select Unlocked properties, which lets you edit the sheet metal definition in the mirrored part.

I work extensively with sheet metal and have recently come across this problem. Wether I create a cone using the - lofted bends (sheet metal) - revolve, (then insert bend feature to make a sheet metal part) I can insert an unfold feature then it will not let me unfold. I can unsupress the flat-pattern feature to get the correct flat.

The Insert Part command lets you create a multibody sheet metal part by inserting a sheet metal body into another sheet metal part. Duplicating Bodies in Sheet Metal Parts. You can create a multibody sheet metal part by duplicating the original part. Overriding Parent Sheet Metal Parameters. All bodies in multibody sheet metal parts inherit the . Help Content Version: SOLIDWORKS Connected (3DEXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative.Create a Base-Flange by clicking Base-Flange/Tab or Insert > Sheet Metal > Base Flange. The sheet metal features appear in the FeatureManager design tree. To bend the sheet metal part, sketch lines on the part as shown.The Insert Part command lets you create a multibody sheet metal part by inserting a sheet metal body into another sheet metal part. Duplicating Bodies in Sheet Metal Parts. You can create a multibody sheet metal part by duplicating the original part. Overriding Parent Sheet Metal Parameters. All bodies in multibody sheet metal parts inherit the .

In the Insert Part PropertyManager:. Under Transfer, select Sheet metal information if you want to transfer the sheet metal and flat pattern information from the original part to the mirrored part, such as fixed face, grain direction, bend lines, and bounding box. You can also select Unlocked properties, which lets you edit the sheet metal definition in the mirrored part.Select a face as the fixed face for the sheet metal part. Set the sheet thickness and default bend radius. Select Keep body if you want to keep the solid body to use in another Convert to Sheet Metal feature. When cleared, the body is consumed by the Convert to Sheet Metal feature. Under Bend Edges, select the model edges that will form bends.Using Sheet Metal Bend Parameters: Simulation: SimulationXpress: Sketching: SOLIDWORKS MBD: . Creating Opposite-Hand Versions of Sheet Metal Parts. . Search 'Mirroring Sheet Metal Parts' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic.As a test, try to insert an axis on the conical face. If you can insert an axis, the model is an exact cone. If you cannot insert an axis, then the model is not an exact cone and cannot be unfolded. However, sheet metal parts created with the Lofted Bends .

Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You can create a configuration in a sheet metal part that shows the flattened part. Sheet Metal Gauge/Bend Table. Sheet metal gauge/bend tables store properties for a designated material.When creating sheet metal parts, the order of design preference is: Sheet metal features (such as Base Flange, Edge Flange, and Miter Flange); Insert Bends feature; Convert to Sheet Metal feature; When using the Insert Bends and Convert to Sheet Metal features, it is best to apply them as early as possible during part design, preferably right after you create the first non-sheet .Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You can create a configuration in a sheet metal part that shows the flattened part. Sheet Metal Gauge/Bend Table. Sheet metal gauge/bend tables store properties for a designated material.The Insert Part command lets you create a multibody sheet metal part by inserting a sheet metal body into another sheet metal part. Duplicating Bodies in Sheet Metal Parts. You can create a multibody sheet metal part by duplicating the original part. Overriding Parent Sheet Metal Parameters. All bodies in multibody sheet metal parts inherit the .

You may want to design a sheet metal part from the flattened state. In this case, you create a sheet metal part, then insert bend lines on which to fold the part. Insert Bends Tool. Convert to Sheet Metal Tool. You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool.As a test, try to insert an axis on the conical face. If you can insert an axis, the model is an exact cone. If you cannot insert an axis, then the model is not an exact cone and cannot be unfolded. However, sheet metal parts created with the Lofted Bends .

The Insert Bends feature also allows you to create rips. Creating Sheet Metal Parts with Conical Faces. Parts with conical faces can also be made of sheet metal. Converting a Shelled Solid Body to a Sheet Metal Part. It is possible to create a solid part, then convert it to sheet metal to add the bends and sheet metal features. Sheet Metal FeaturesCreate a Base-Flange by clicking Base-Flange/Tab or Insert > Sheet Metal > Base Flange. The sheet metal features appear in the FeatureManager design tree. To bend the sheet metal part, sketch lines on the part as shown.

China fiber optic junction boxes manufacturers and fiber optic junction boxes factory. We company has the complete production and development system, as well as the comprehensive testing equipment.

insert a bend on sheet metal parts in solidworks|solidworks unbend sheet metal