cnc from design to machining CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, . Order parts and accessories for all types of CNC machines. Cutting tools, workholders, toolholders, measurement and calibration devices, and more.

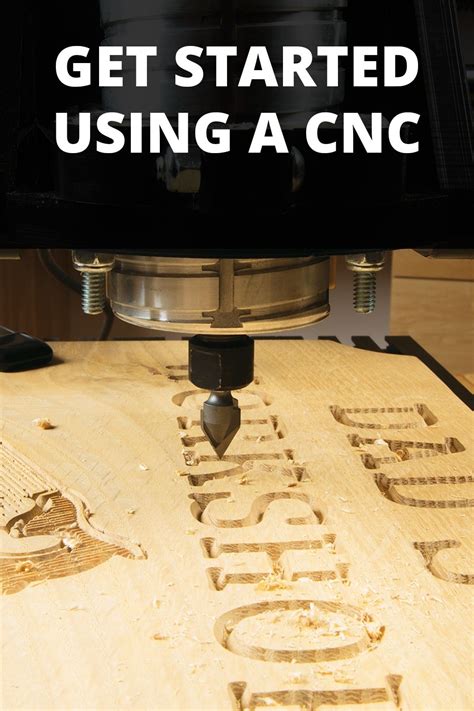

0 · small cnc machine wood projects

1 · free cnc projects for beginners

2 · free cnc patterns for wood

3 · cnc machine design pdf

4 · cnc machine design ideas

5 · cnc machine basic knowledge

6 · cnc design website

7 · best cnc projects for beginners

Absolute Machine Tools is a master importer and distributor of CNC machine tools throughout North America. Comprehensive Metal Cutting and Automation Products for Diverse Processes and Applications in the manufacturing industry.

In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance. CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, .Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance.

CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made .In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining. Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to . CNC machining is among the most popular manufacturing methods because the process is highly versatile, repeatable, and reliable — plus, it is compatible with a broad range of materials, from wood and plastic to foam and metal.

Get in-depth design advice to optimize your plastic and metal parts for CNC machining. Designing with machining in mind can accelerate production time and reduce production costs. There are many design considerations involved when creating CNC machined plastic and metal parts. Achieving CNC precision requires careful material selection and attention to geometric constraints. This guide explores how these factors impact machining accuracy, cost, and performance, offering practical tips for designing high-quality components. Here are some basic rules to take into consideration when designing CNC machining. Do not use sizes below 20 points when machining text to avoid mistakes within the engraved text. True, CNC machining is versatile, and not all designs are possible.

What exactly is computer-numerical-controlled (CNC) machining? It’s a means to make parts by removing material via high-speed, precision robotic machines that use an array of cutting tools.Design for CNC machining. In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance.

CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made .In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining. Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to . CNC machining is among the most popular manufacturing methods because the process is highly versatile, repeatable, and reliable — plus, it is compatible with a broad range of materials, from wood and plastic to foam and metal.

small cnc machine wood projects

Get in-depth design advice to optimize your plastic and metal parts for CNC machining. Designing with machining in mind can accelerate production time and reduce production costs. There are many design considerations involved when creating CNC machined plastic and metal parts. Achieving CNC precision requires careful material selection and attention to geometric constraints. This guide explores how these factors impact machining accuracy, cost, and performance, offering practical tips for designing high-quality components. Here are some basic rules to take into consideration when designing CNC machining. Do not use sizes below 20 points when machining text to avoid mistakes within the engraved text. True, CNC machining is versatile, and not all designs are possible.

small electric meter box

free cnc projects for beginners

eMachineShop offers CNC machining, sheet metal fabrication, 3D printing, injection molding and various finishing options. Simply upload your design, enter your specifications and get a reliable manufacturing quote.

cnc from design to machining|free cnc projects for beginners