sheet metal problems Sheet metal defects affect the appearance, function or structural integrity of the sheet metal. Learn the defects and avoid them in the sheet metal process. Get the best deals for Steel Glide Tool Box at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

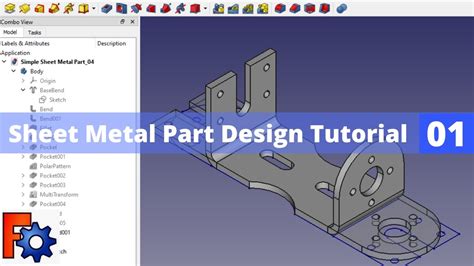

0 · sheet metal parts design problems

1 · sheet metal manufacturing defects

2 · sheet metal design errors

3 · sheet metal defects explained

4 · problems with sheet metal bending

5 · how to solve sheet metal problems

6 · how to fix sheet metal problems

7 · how to fix sheet metal defects

What they work well with: Inset cabinetry with exposed hinges, stainless steel, white marble and honed black countertops, industrial-style lighting.

sheet metal parts design problems

Sheet metal defects affect the appearance, function or structural integrity of the sheet metal. Learn the defects and avoid them in the sheet metal process. Common Tolerancing Problems in Metal Fabrication. We frequently receive RFQs for parts with tolerances that exceed what is achievable in standard fabrication. Most of these .Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .

Defects like cracks, warping, and twisting can plague bent parts, compromising their quality and functionality. This article dives into the causes behind these issues, from tensile stress to die rigidity problems, and provides .

Dozens of possible parameters may have changed, but the more common ones include the sheet metal composition and mechanical properties, the die, the lubricant, and the .

In Part 1 of this series, published in the January-February 2021 issue of MetalForming, we covered the key sheet metal characteristics and properties that can help in your fact-finding mission. Here we present some . Finding the root causes of sheet metal forming problems. Tips for conducting a reliable correlation analysis. By Bill Frahm. February 8, 2023. For metal forming companies to make the most of analytical technology, they will . Well the problem is that whoever designed this does not understand the real world of bending sheet metal. There must be arcs for the bend and the material uniform thickness. Note that without the arc the corner .

Sheet metal stamping parts are widely used in various industries, suitable for a variety of metal sheet materials, mainly including: carbon steel, stainless steel, cold rolled steel, aluminum alloy, copper alloy, galvanized .

Sheet metal processing manufacturers generally have many kinds of processes, and bending process is one of them, which is often used. Problems are inevitable in this processing process. Then I will introduce you how to .I've attempted to do this by modifying the sheet metal flange profile, drafting a solid with extruded cuts attempting to convert to sheet metal, and a few others not worth mentioning. The bends connecting the horizontal lines above and below the compound curve section cannot be collected for some reason.

Sheet metal flat pattern problems Thread starter SiW979; Start date Jan 23, 2012; Status Not open for further replies. Jan 23, 2012 #1 SiW979 Mechanical. Nov 16, 2007 804 GB. The majority of our products are based on large weldments that we use NX sheetmetal to design and create the flat patterns. Sheet metal to us can be up to 25mm thick, and .It shouldn't be a problem. You can edit the flat pattern feature properties and try toggling the corner treatment setting. You can also add corner trims to the flat by hitting the flatten button then going to Insert > sheet metal > corner trim. This will give you different options than adding a bend relief in the folded state.Buy Sheet metal pattern drafting and shop problems. by James Sharkey Daugherty online at Alibris. We have new and used copies available, in 0 edition - starting at .98. . Add to Cart Add this copy of Sheet-Metal Pattern Drafting & Shop Problems to cart. .81, good condition, Sold by Bonita rated 4.0 out of 5 stars, ships from Newport .Word problems; Geometry; Math is a subject that intimidates many people. The best way to improve your mathematical ability is to practice, practice, practice! . The Sheet Metal, Air, Rail, and Transportation Workers (SMART) Local 36 Sheet Metal Test is the apprenticeship test given in St. Louis, Missouri. This exam only contains four categories:

Sheet metal design problems. curtis_pope Member Posts: 4 . It mounts to a sheet metal bracket that forms the bottom and front of the enclosure. What I want is for the front to be all the way across, but cut out in the bottom so that the extrusion will sit flush in there. I took the sheetmetal and cut out a notch to form that cutout, but I can . Sheet benders, also known as press brakes, are essential tools in metal fabrication, shaping metal sheets into intricate and precise forms. However, issues during bending can arise due to various factors, hindering productivity and quality. This article aims to provide comprehensive troubleshooting guidance for common problems encountered when working .

sheet metal manufacturing defects

Here we have maybe the last of a good line of Sheet Metal Pattern Development books. The last, as I have said in my other reviews, due to the advances in technology whereby everything in this development book is now done on a CNC operated machine. Hey All, Sheet metal scrub (me) is trying to do something that seems beyond my reasoning. Have tried a few ways and gave up due to lack of skill/understanding of the sheet metal process (have a training book that I just havent had time to go thru, sadly!). Wondered if someone could point me in the right direction with the attached file. Sometimes various problems can occur, or you may deal with one part of your system breaking over and over again. . Call Purl’s Sheet Metal & Air Conditioning today and schedule an air conditioning installation in Fresno with one of our installation experts. Twitter Link. Tags: Air Conditioning Installation, Fresno Friday, August 22nd, . Addresses real world issues when butt welding auto body sheet metal such as welder settings, unexpected problems, and solutions.https://www.youtube.com/chann.

Sheet Metal/HVAC Pro provides instant solutions in dimensional format for Right Triangle problems for sheet metal problems. A Right Triangle is calculated simply by entering two of four variables: 1) (Run) 2) (Rise) 3) (Diagonal, or .

They come in a variety of sizes and can be used to cut different types of metal, including sheet metal, plate metal, and bar stock. Like any other machine, metal shear machines can sometimes experience problems. These problems can range from minor issues, such as dull blades, to more serious issues, such as a malfunctioning motor.The most common problems in the cold metal sheet forming [6]. the workpiece quality depends on how much the BHF presses on the blank holder: if it is too high, then the flow of material into the .The document provides a general description of the most common sheet metal “problems” and misunderstandings, and compiles issues reported in over 3000 service requests from sheet metal customers. Your Feedback Requested We would like to hear your feedback and also suggestions for new topics. After reviewing Sheet-Metal Pattern Drafting and Shop Problems [Daugherty-Powell and Foster] on Amazon.com. *FREE* shipping on qualifying offers. Sheet-Metal Pattern Drafting and Shop Problems . Sheet-Metal Pattern Drafting and Shop Problems Paperback – January 1, 1978 . by Daugherty-Powell and Foster (Author) See all formats and editions .

Sheet metal rolling machines are essential tools in the manufacturing industry, used to shape and form metal sheets into desired shapes. However, like any machinery, they can encounter various problems that can affect their performance and efficiency.factors are reflectivity, thickness and flammability. Reflectivity causes a problem because the cutting beam gets scattered. Material that is too thick has the same problem: molten metal scatters the beam before the part is fully cut. We can cut metal as thick as 3/8" but the edge quality suffers greatly.

Jeff I am not sure what you need but Direct Sheet metal in El Cajon ca. is a good source and also Brookville is also another good source. Good Luck Fuzzy Fuzzy Knight, Mar 18, 2014. . Ive never had problems with them in the past either. Customer service is a big pet pieve of mine as well. I believe if you look hard enough you will find neg . I need help cutting perforated sheet metal. My setup is a Hypertherm Powermax 45XP on a 2x4’ Avid CNC plasma table controlled by Mach4. I realize the answer to my question might be in the mach 4 settings but I thought of asking here as well. My design is a simple rectangle. The torch drops down, ignites and then stops immediately. Is there some setting (a . Sheet Metal Finishing. The finish you select for your sheet metal parts can present surprising complications. Custom paints and other specialty finishes can dramatically derail your budget and timeline.. Very recently, a customer specified a name-brand paint that had not only an 8-week lead time but also a jaw-dropping ,000-per-box price tag!

Sheet-metal pattern drafting and shop problems Hardcover – January 1, 1961 by James Sharkey Daugherty (Author) 5.0 5.0 out of 5 stars 3 ratings

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight . Examples-sheet metal formed . . 3D Problems In 1-D, assuming perfectly plastic, yielding at: € σ=Y € σ .

Now that the common sheet metal brake problems and solutions are discussed, it is important to know that not investing in a quality setup can be a huge mistake in sheet metal bending. Therefore, one must invest in a high-quality bending brake set up so that the machine-errors can be prevented and high-quality products can be accomplished.

eMachineShop has machined aluminum parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA.

sheet metal problems|how to solve sheet metal problems