what type of parts you intend to make cnc The size of the parts you intend to handle, and process is also critical. For large and heavy materials, go for a larger and more robust CNC waterjet machine design such as the gantry bridge type. In situations where . Packaged in a sleek slipcase, The 7 Savage Boxset includes a meticulously crafted 60-page hardback book. With exclusive photographs by acclaimed metal photographers such .

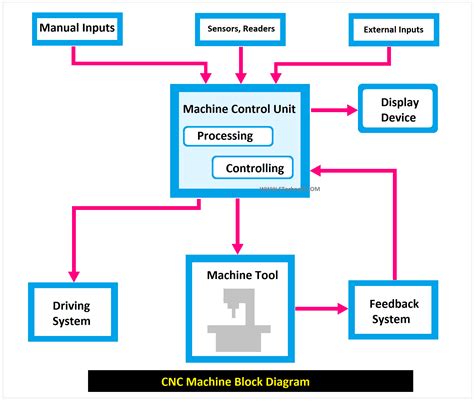

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · main components of cnc machine

3 · cnc machine spare parts list

4 · cnc machine parts list pdf

5 · cnc machine parts list

6 · cnc machine parts diagram

7 · block diagram of cnc machine

Warom BXJ8050-20/6 Series GRP Explosion-proof Junction Boxes for Hazardous Areas (Ex e). Suitable for Zone 1 and Zone 2. IECEx certified.

schematic diagram of cnc machine

In selecting the appropriate material for your CNC machined part, it is crucial to thoroughly evaluate various factors, including cost, part weight, electrical conductivity, heat resistance, surface finish, and the intended application of . In this guide, we'll explore the types of parts you can create using CNC turning technology. From simple components to intricate designs, CNC turning opens up a world of .

parts made by cnc machine

High-precision CNC mills and lathes can achieve tight tolerances on various materials, making them suitable for complex requirements. Size of Production. Consider the volume and size of the parts you intend to produce. .

CamBam :CNC Cad and Cam software very supported with addons and plugins $ 149.00. MACH 3: 6 Axis CNC stepper and Servo motor control software by Artsoft $ 175.00. SheetCAM TNG – The Ultimate CNC Cutting Path Software $ .

The size of the parts you intend to handle, and process is also critical. For large and heavy materials, go for a larger and more robust CNC waterjet machine design such as the gantry bridge type. In situations where .

There are form cutters that would allow you to use the 4th axis the same way you'd use an indexer on a manual mill, there are now carbide insertable cutters that will work, but it's a big investment for few parts and sometimes the finished parts are still not as accurate as a shaped or hobbed (meaning generated) gear.

The Bandit CNC was designed by Summit/Dana Industrial and then purchased by Allen Bradley. If you do a search for Bandit CNC repair you will get several sites offering parts and repair. The factory site we always used for parts and info was in Bozeman, Montana. I had a number of 406-587-4511 but don't know if it is still current. 3- If the sides of the part aren't square to the bottom when you clamp them in the vise, then that too can pull the part out of "square" when you clamp. On parts that are thin like that, you need to stand them up in the vise, and/or clamped against a good angle plate, and trim the thin edges that will get clamped between the vise jaws.

For example, if you’re going to use a 1/8th bit to cut out a hole for a screen, make a rounded rectangle with .063″ corners. This way, the machine will cut exactly what you design, because you’ve planned for the limitations. Remember, just because you can draw it on a computer screen doesn’t mean you can make it in real life.

main components of cnc machine

The days of making parts in multiple operations seem to be gone but it all depends on the type of part. We can help you determine which is more cost effective. In either case our equipment can drop your part complete or we can make it in 2 ops with our screw machines providing a blank part and our CNC Machining to finish the part.Cnc machinist here, some complicated parts that need things like a 6 axis cnc can take up to 10 hours of programming and setup time, not to mention harder materials like ss require more expensive tools or the machine has to be run slower. There are probably more appropriate forum communities out there for better specifics on the type of work you are attempting. But as for the generalities, the Kress 1050 offers speeds down to 5000rpm which may be beneficial. You just need to make sure you can get collets all the way down to the size bits you are using. I’m curious to understand the difference between the R8 ‘new stuff’ of ‘auto plane’ and the regular ‘cplane to object’ approach. I’ve decided that Cplanes are in fact crucial to the whole parametric ideologies. And I intend to focus on them a fair amount. I believe that no matter the part type, the “Cplanes” should be exploited as much as other parametric programs do .

Ensure that your design captures the precise size and dimensions of the parts you intend to produce. Depending on the parts you want to create, the software allows you to develop 3D models allows you to assess the parts, and make corrections before you begin their production. It is important to note that this process requires that you have the . It sounds like maybe you intend to focus on manual machining and not so much on CNC? While that's a necessary and worthwhile skillset, it's not particularly the future of american manufacturing. . This may be true of a lot of large company jobs of this type. . then move into CNC. Once you know how to make the parts, learning CNC is much easier. You may have believed long and hard concerning read more utilizing your CNC equipment for things like packaging, or simply making a attractive product out of a block of wood, however if you intend to do more than just make prototypes for goods, or easy items then you may intend to consider a few of the various choices you have offered. This .

If you intend to cut acrylic materials, consider using CNC machines such as lathes, routers, or mills. Choosing the correct cutter is also essential. If you experience issues with acrylic melting or cracking, adjust feeds and speeds of machining .

It's important to buy the machine that's capable of producing the work you intend to do in the time frames you expect it do to so. If you can be flexible with the time and are not planning on this to be a long term production thing, then you can probably leverage a more modest machine for the work.

You should also take factors like the required surface finish, complexity of parts, cycle and machining times, and part rejection rates, which, in the end, affect CNC machining costs. About Kevin As a registered civil .I am looking to get my first “metal” milling machine for conversion to CNC. I want to cut aluminum, and some type of steel would also be excellent ( I need to learn about different metal compositions). . but when I was going for a mill I had the same intent as you (I think - some experience, wanted to fuck about and find out) similar .Nesting parts . If you want to cut duplicates of the same part or multiple different parts on your material at one time, you can use the nesting function in Sheetcam, VCarve, or other design software. Vcarve is the most efficient. Nesting multiple parts will ensure that you make the best use of your material.Image Credit. Phone Cases. Seeing as phone cases have become portable fashion accessories in their own right, more and more people are turning to custom-made cases. CNC machines allow you to create phone cases from plastic, but everyone has one of those. So, instead, consider making a wooden phone case.

Coming from a cabinet guy, unless you have software to auto generate all the parts a CNC isn't very useful. Mozaik was amazing but it's 0 to start with and requires some setup. As for a CNC, you will need full sheet capacity to make it useful and that ups the price significantly.Factors such as the type of materials you intend to work with, the desired precision, production volume, and future scalability should all be taken into account. Understanding your needs will help you determine the right type and size of CNC machine to meet your requirements effectively. 2. Machine Accuracy and Precision:\

Choosing the right type of CNC lathe or mill is crucial to ensure efficient and accurate machining. It is important to consider factors such as the complexity of the part, required tolerances, and the type of material being machined. . you can ensure that your chosen machine is well-suited for the materials you intend to work with, allowing . Before selecting a press brake, you must first choose the sort of metal you intend to bend (stainless steel, 16 gauge mild steel, etc.) Then you must define the specific features to be considered .Ya you get to a point where time saving of 1 second per rapids isn't worth the risk hard crashing or premature wear. Haha. Do you have a shop you can build all this in? Curious how you plan to do some of this. A CNC Router or CNC Milling machine is a great addition to any workshop. Whether in a home workshop for hobby use, or a business workshop for commercial use, Maker Store offers a CNC machine for every application. Deciding what components are needed to achieve your ‘first cut’ can be difficult and with the large number of choices available on the .

sheet metal worker training

If you are considering the addition of a CNC router in your workshop you might be curious about what it can make. CNC machines are invaluable tools that make manufacturing easier for countless products across a variety of industries. Though CNC machines are commonly used for woodworking they are also an essential tool for cutting, [.]

cnc machine spare parts list

cnc machine parts list pdf

cnc machine parts list

Oldcastle Infrastructure offers junction boxes in a variety of sizes and customization to meet your application needs. Underground junction boxes protect and provide easy access to communications, splice connections, and electrical utility wiring.

what type of parts you intend to make cnc|parts made by cnc machine