application of nc and cnc machine Simply put, CNC machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) programs to control the movement of cutting tools and workpieces to create nearly any custom shape imaginable. West Coast Sheet Metal & Laser Cutting - Established 2006 is located in Karnup, WA 6176. Click through for driving directions on Whereis®.

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

Your Trusted Sheet Metal Fabrication Service Provider, Since 2001. Get Fast Sheet Metal Quote Today! We Offer High Precision And Durability Sheet Metal Parts.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Simply put, CNC machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) programs to control the movement of cutting tools and workpieces to create nearly any custom shape imaginable.

Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC .CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. . The main difference between NC and CNC machines is that NC machines are controlled by a pre-programmed set of alphanumeric codes, while CNC machines are controlled by a computer-generated program using G . In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

In this article, we will first have a glance at CNC language, and then we will go for the different types of CNC machines and their applications. We will see their working process on YouTube videos. Before diving into types of CNC .CNC machining starts with programming, where the geometric data of the workpiece and processing information are written into a CNC machining program using specific codes and .CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots .

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Simply put, CNC machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) programs to control the movement of cutting tools and workpieces to create nearly any custom shape imaginable. in this post, you’ll learn what is NC machine and its working, types of NC system, basic components, NC coordinate system, application, advantages and more with PDF download. In conventional machine parameters like feed, depth of .

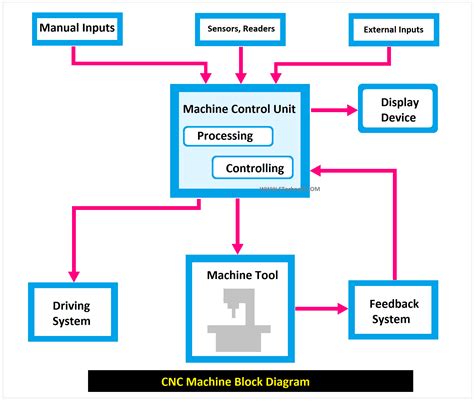

schematic diagram of cnc machine

Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling)

The main difference between NC and CNC machines is that NC machines are controlled by a pre-programmed set of alphanumeric codes, while CNC machines are controlled by a computer-generated program using G-Codes .

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

In this article, we will first have a glance at CNC language, and then we will go for the different types of CNC machines and their applications. We will see their working process on YouTube videos. Before diving into types of CNC machines, let’s talk about the CNC language.

CNC machining starts with programming, where the geometric data of the workpiece and processing information are written into a CNC machining program using specific codes and formats. After entering this program into the CNC system, the system processes the data and outputs various information and instructions.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

Simply put, CNC machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) programs to control the movement of cutting tools and workpieces to create nearly any custom shape imaginable. in this post, you’ll learn what is NC machine and its working, types of NC system, basic components, NC coordinate system, application, advantages and more with PDF download. In conventional machine parameters like feed, depth of . Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.

CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling) The main difference between NC and CNC machines is that NC machines are controlled by a pre-programmed set of alphanumeric codes, while CNC machines are controlled by a computer-generated program using G-Codes . In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

In this article, we will first have a glance at CNC language, and then we will go for the different types of CNC machines and their applications. We will see their working process on YouTube videos. Before diving into types of CNC machines, let’s talk about the CNC language.CNC machining starts with programming, where the geometric data of the workpiece and processing information are written into a CNC machining program using specific codes and formats. After entering this program into the CNC system, the system processes the data and outputs various information and instructions.

products made by milling machine

carvewright cx cnc machine

carnaud metal box crown packaging

carnaud metal box logo

industries that use cnc machines

To gas weld sheet metal, you will need to have a gas welding kit, protective gear, and a clean working area. Follow these steps to gas weld sheet metal: Choose the right gas and tip size for your sheet metal. Clean the metal surfaces with a wire brush or grinder. Secure the metal pieces in place with clamps or a vice.

application of nc and cnc machine|cnc machine work needed