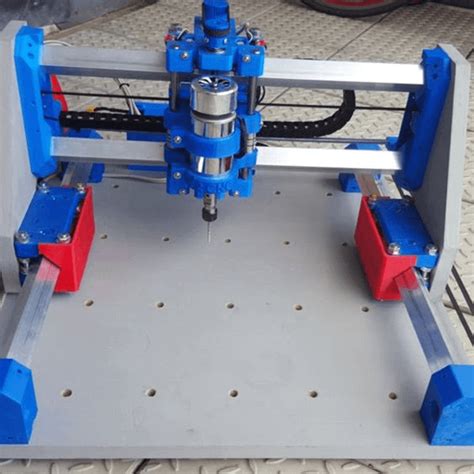

cnc machining processed mechanical parts The CNC machine removes parts of the workpiece by machining operations such as turning, drilling, or milling, according to codes (g-code and m-code) obtained from the CAD model and containing instructions on machining parameters. CNC machining process is compatible with many metals, plastics, wood, and composite materials.

There are several types of punching operations, each serving specific purposes: Blanking: In blanking, a piece of material is removed from the center of the sheet to create a .

0 · parts made by cnc machine

1 · online cnc shop

2 · cnc replacement parts manufacturer

3 · cnc machining parts usa

4 · cnc machining parts supplier

5 · cnc machining parts manufacturer

6 · cnc machining custom made parts

7 · cnc machine parts list

Metallic fabrics are fabrics that incorporate metallic elements - characteristics, uses, and unique qualities of metallic fabrics, such as metallic brocade, lamé, sequins, lurex, and metallic-coated fabrics.

parts made by cnc machine

2024 aluminum sheet metal

However, what exactly defines CNC machine parts? And what attributes render them so vital? This article delves into CNC machining and CNC machined parts, compiling comprehensive and up-to-date information on all aspects you . CNC manufacturing operations include CNC drilling, milling, turning, and grinding. Plus, you can create CNC parts from any metal, plastic, or any other material that can be cut without severe degradation. CNC Machining .CNC machining process of shaft parts. Shaft parts are one of the products we received the most orders. According to the structure of the shaft, it can be divided into three types: optical axis, step axis and special axis.Their role is to support .Explore the different types of machining processes, from conventional methods like turning, milling, and drilling to non-conventional techniques such as EDM and chemical machining. Learn how each process is used to shape materials, create intricate designs, and work with hard-to-machine substances. This guide helps you understand which machining methods are best .

Chemical finishing processes in CNC machining involve the application of chemical agents to alter the surface of machined parts. Unlike mechanical methods that physically remove or deform the surface layer, .

The CNC machine removes parts of the workpiece by machining operations such as turning, drilling, or milling, according to codes (g-code and m-code) obtained from the CAD model and containing instructions on machining parameters. CNC machining process is compatible with many metals, plastics, wood, and composite materials. Despite its mediocre mechanical properties, it is one of the popular CNC machining and milling plastics for many specific applications.One of the best ways to manufacture Teflon parts is CNC machining. This article explores the ins and outs of Teflon processing: its material properties, processing advantages, common applications, and more. Automobile parts such as fuel system components, belt buckles, and various mechanical parts. Screws, nuts, and other fastening components for its strength and ease of threading. . Based on the above considerations, select the plastic material that best meets the requirements for the CNC machining process. Fig. 2: Simple CNC Machined Parts . The Significance of Aluminum in CNC Machining. CNC machining, an advanced manufacturing process driven by computerized control systems, has revolutionized the production of precision parts across various industries.While numerous materials can be used in CNC machining, aluminum stands out for its exceptional properties, making it a preferred choice for .

CNC Machining Services. Surface roughness Ra 0.8-3.2 µm; Precision shop tolerance ±0.0004 in. (0.01mm) 5 Axis machined prototype parts in as fast as 1 day

In engineering and manufacturing, mechanical parts play a crucial role. Understanding the intricacies of mechanical part production is essential for ensuring high-quality products and efficient processes. Let’s delve into various aspects of mechanical part production. Contents hide 1 An Overview of Mechanical Part Production 2 Process Preparation Flow for Mechanical Part .The Automated Process. The CNC machining process starts with a digital blueprint created using computer-aided design (CAD) software. . Applications: Commonly used in couplings, spindles, bolts, nuts, and automotive parts. Mechanical Properties: – Yield Tensile Strength: 655 MPa – Shear Modulus: 80 GPa – Elongation at Break: 19% A vertical machining center is a mechanical device with a vertical spindle. Its structure is mostly fixed column. The worktable is rectangular and has no indexing and rotation function. It is suitable for processing discs, sleeves, and plate parts.

online cnc shop

CNC machining plastic is one of the popular machining processes across different industries. Manufacturers often make machined parts for diverse applications because of plastic material availability. Besides, the CNC machining process is more accurate and fast and offers the preferred tolerances in plastic machined parts since it uses computer numerical control to . Advantages of CNC Machining: Limitations of CNC Machining: Precision and Accuracy: CNC machining offers exceptional precision and tight tolerances. Cost for Complex Geometries: Creating complex parts can be time-consuming and costly. Superior Surface Finish: CNC machining can achieve high-quality surface finishes. Material Removal Efficiency: .Additional Processes After machining and heat treating, the precision machining process ends with finishing operations. These steps ensure the parts are ready for packaging and use, and include: • Deburring. Machining processes may leave behind excess material or surface deformations. Deburring can be a manual, mechanical, or chemical process The text provides a holistic understanding of machining processes and machines in manufacturing; it enables critical thinking through mathematical modeling and problem solving, and offers 200 .

Online CNC Machining Services: Offering Turning, Milling, and Wire EDM. Discover our CNC machining capabilities, available materials, and surface finish options. . advanced CNC machine shops • Parts as Fast as 3 days. Request .

We specialize in the high-precision CNC machining of mechanical parts, expertly produced in large quantities with excellent quality. 4. Our one-stop CNC machining service offers a complete solution to making machinery parts, from .Step 1: The Quoting Process Harvan Manufacturing has a wide range of processes and capabilities that we take into consideration when quoting. Since the majority of our customers require very specific parts and materials, we take time to ensure we can procure those unique materials as well as perform the operations necessary to hold tolerances and create perfect .

The parts of the workpiece formed through CNC machining typically start out as initial designs. It is done via computer-aided design or CAD software. In the part designing phase, engineers and manufacturers carefully think about each aspect of the final product. The CNC Machining Process. The CNC process starts with using CAD software to design and define a part precisely. Afterward, the CAM software translates the digital model into controls for the MCU. . Nylon has similar traits to ABS and can replace numerous mechanical parts like gears and bearings. Composite materials combine fibers like carbon . The machining process of mechanical parts is a crucial part of the modern manufacturing industry and is directly related to the accuracy, surface quality, and overall performance of parts. In this process, CNC machining technology has become the mainstay of the manufacturing industry, and the movement of tools is precisely controlled by . Although CNC machining parts don’t use labor-intensive tooling, the production process is highly efficient. Some CNC machines have faster machining centers equipped with linear guide rails at rapid rates. Besides, the speed of CNC machining centers and the one-step attribute of the machining process quicker lead times for machined parts.

Post-processing is often necessary after CNC machining plastic parts to achieve the desired surface finish, precision, or functional characteristics. Here are some standard post-processing options for CNC-machined plastic components: Sanding and Polishing. After CNC machining, plastic parts may have rough edges, visible tool marks, or burrs. A CNC vise fixture provides higher levels of precision than the traditional mechanical vise commonly used in woodworking and manual machining. These CNC vises deliver impressive clamping power via a pneumatic/hydraulic screw mechanism. . As a result, you may require a custom CNC fixture to effectively machine parts. Like its name, it is a .

The CNC machining process can create precise parts and components with tight tolerances of ±0.025 mm and fine details. However, parts fabricated with CNC milling machines often have visible marks. Hence, surface finishing is a core part of the manufacturing process because it helps enhance the aesthetic, corrosion, and wear resistance of .In conclusion, CNC machining is a complex but highly efficient manufacturing process. It involves several crucial steps, from designing the CAD model to performing the actual machining operations and completing necessary post-processing tasks. The precision and repeatability offered by CNC machining make it a preferred choice for various .Xiamen Hydronova Energy Technology Co., Ltd.: High quality and bespoke CNC machining services. SGS/ISO9001 custom CNC machining parts manufacturer. Your reliable partner for CNC manufacturing, prototyping and production of custom parts.

Exploring the diverse types of CNC lathe machines reveals a wide range of options tailored to specific machining needs. Understanding these variations is essential for selecting the most suitable machine for your projects.

cnc machining processed mechanical parts|cnc machining parts usa