cnc machine power CNC machine power consumption can be calculated by measuring the current and voltage used by the machine during operation and multiplying these values by the time the machine is in use. This calculation will result in . When attempting to replace an electrical outlet, an issue may arise due to inadequate wire length inside the junction box, which does not meet the minimum requirements. Here is how to address this problem.

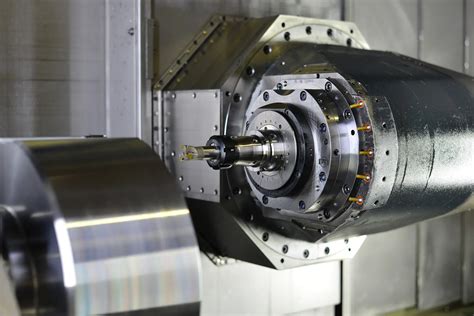

0 · spindle for cnc machine

1 · power supply for cnc machine

2 · cnc router power supply

3 · cnc power supply

4 · cnc machine power requirements

5 · cnc machine power cord

6 · cnc machine power consumption

7 · best cnc spindle for milling

Buy Wiremold BW2-D Metal Outlet Box With Duplex/Faceplate Outlet Kit, White online at DKHardware.com. Our Electrical & Gas category offers a great selection of Conduit Raceways & Mounting products at the best price!

CNC machine power consumption can be calculated by measuring the current and voltage used by the machine during operation and multiplying these values by the time the machine is in use. This calculation will result in .Power consumption is an essential aspect of CNC machine operation. By following the steps outlined in this guide, you can accurately calculate the power consumption of your CNC . Most CNC machines use around 30-40 amps in 220v single phase and a bit less amperage in 208v 3 phase, though some require less and others require significantly more. It really depends on how the machine is outfitted .Understanding the power requirements of CNC machines is essential for manufacturers to optimize energy usage, reduce costs, and minimize their carbon footprint. In this blog post, we .

Understanding the power requirements of CNC machines is integral to their efficient and safe operation. By considering factors like machine size, spindle motor, drive motors, and auxiliary . CNC machines require a specific power requirement to operate efficiently. Learn about the proper voltage levels and why they're so important in our informative post.The spindle power required at the motor is more than the cutting power required at the chuck, because of mechanical losses in spindle bearings and belt, and power required to rotate the . Calculating the power consumption of a CNC machine is important for determining the cost of running the machine and for ensuring that the machine is operating efficiently. The .

Many ways exist to work around a lack of power, including high-speed milling methods and alternate machining technologies, but by approximating your required power you can increase MRR and, therefore, . CNC machine power consumption can be calculated by measuring the current and voltage used by the machine during operation and multiplying these values by the time the machine is in use. This calculation will result in the number .Calculating the power required (in kW or HP) from a CNC machine to perform a particular milling, turning, or drilling operation is essential to validate that our equipment can execute the machining operation without getting too close to its power limit. Use our Online Calculator or learn how to compute it (Including detailed formulas).Power consumption is an essential aspect of CNC machine operation. By following the steps outlined in this guide, you can accurately calculate the power consumption of your CNC machine and estimate the cost of energy consumption.

spindle for cnc machine

Most CNC machines use around 30-40 amps in 220v single phase and a bit less amperage in 208v 3 phase, though some require less and others require significantly more. It really depends on how the machine is outfitted such as the size of the spindle and motor size of the vacuum pump.

Understanding the power requirements of CNC machines is essential for manufacturers to optimize energy usage, reduce costs, and minimize their carbon footprint. In this blog post, we will delve deep into the topic of CNC machine power consumption, exploring its factors, measurements, and ways to optimize energy usage.Understanding the power requirements of CNC machines is integral to their efficient and safe operation. By considering factors like machine size, spindle motor, drive motors, and auxiliary components, you can determine the power ratings necessary for your CNC machine.

CNC machines require a specific power requirement to operate efficiently. Learn about the proper voltage levels and why they're so important in our informative post.The spindle power required at the motor is more than the cutting power required at the chuck, because of mechanical losses in spindle bearings and belt, and power required to rotate the spindle itself. The mechanical losses will typically be about 20 % for most machines, which means the spindle motor power is 1.2 times the cutting power. Calculating the power consumption of a CNC machine is important for determining the cost of running the machine and for ensuring that the machine is operating efficiently. The first step in calculating the power consumption of a CNC . Many ways exist to work around a lack of power, including high-speed milling methods and alternate machining technologies, but by approximating your required power you can increase MRR and, therefore, machining productivity.

power supply for cnc machine

CNC machine power consumption can be calculated by measuring the current and voltage used by the machine during operation and multiplying these values by the time the machine is in use. This calculation will result in the number .

Calculating the power required (in kW or HP) from a CNC machine to perform a particular milling, turning, or drilling operation is essential to validate that our equipment can execute the machining operation without getting too close to its power limit. Use our Online Calculator or learn how to compute it (Including detailed formulas).Power consumption is an essential aspect of CNC machine operation. By following the steps outlined in this guide, you can accurately calculate the power consumption of your CNC machine and estimate the cost of energy consumption.

electrical distribution box hs code

Most CNC machines use around 30-40 amps in 220v single phase and a bit less amperage in 208v 3 phase, though some require less and others require significantly more. It really depends on how the machine is outfitted such as the size of the spindle and motor size of the vacuum pump.Understanding the power requirements of CNC machines is essential for manufacturers to optimize energy usage, reduce costs, and minimize their carbon footprint. In this blog post, we will delve deep into the topic of CNC machine power consumption, exploring its factors, measurements, and ways to optimize energy usage.

Understanding the power requirements of CNC machines is integral to their efficient and safe operation. By considering factors like machine size, spindle motor, drive motors, and auxiliary components, you can determine the power ratings necessary for your CNC machine. CNC machines require a specific power requirement to operate efficiently. Learn about the proper voltage levels and why they're so important in our informative post.The spindle power required at the motor is more than the cutting power required at the chuck, because of mechanical losses in spindle bearings and belt, and power required to rotate the spindle itself. The mechanical losses will typically be about 20 % for most machines, which means the spindle motor power is 1.2 times the cutting power.

Calculating the power consumption of a CNC machine is important for determining the cost of running the machine and for ensuring that the machine is operating efficiently. The first step in calculating the power consumption of a CNC .

cnc router power supply

cnc power supply

cnc machine power requirements

cnc machine power cord

Use to relocate a switch to a new location, add a wall switch to a pull-chain light, or use anywhere else you may need to add a switch. This Kit is intended for indoor use; a receiver or switch installed on an outdoor light will need protection from the elements.

cnc machine power|cnc router power supply