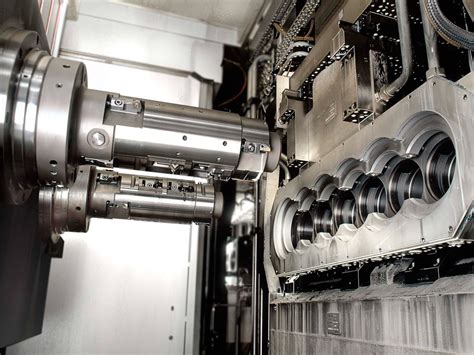

+cnc +machine +for +automotive +industry Computer Numerical Control (CNC) machining is a production technique that uses computer-controlled machines to accurately cut, shape and form parts. It can create complex geometries from materials such as metal (aluminum, steel, titanium), plastic or wood.

So yes, you’ll need some kind of junction box there. If the existing junction box for some reason sticks out past the joist at a depth greater than the finish ceiling material (usually 1/2” drywall) then yes you might want to replace or adjust it to be flush with the bottom of the joist.

0 · cnc machining in automotive industry

1 · cnc machine automotive parts

2 · cnc automotive parts

3 · c&c automotive repair

4 · c&c automotive refinishing

5 · c&c auto shop

6 · c&c auto repair

7 · automotive cnc machining

Wires, receptacles and switches need adequate space. Crowded boxes can damage wires, resulting in a fire or shock hazard. You can use the chart below to calculate the required box size. Add up the numbers for the correspond- ing components in the box to find how many cubic inches you’ll need.

CNC Automotive machining is a production method that employs computer-controlled equipment to cut, mold, and automotive parts precisely. Also, this process can make intricate shapes out of materials like plastic or metal. In the automotive industry, CNC machined prototypes can include anything from headlight covers to engines. But CNC also helps to make end-use car parts. They include cylinder heads, starter motors, gearboxes, and one-off . CNC Automotive machining is a production method that employs computer-controlled equipment to cut, mold, and automotive parts precisely. Also, this process can make intricate shapes out of materials like plastic or metal.

In the automotive industry, CNC machined prototypes can include anything from headlight covers to engines. But CNC also helps to make end-use car parts. They include cylinder heads, starter motors, gearboxes, and one-off custom components for rare and vintage cars.

CNC machining has become integral to the automotive industry, offering several compelling advantages that enhance the manufacturing process. CNC benefits span from increased production speeds to heightened precision, each contributing significantly to the industry’s efficiency and product quality.Computer Numerical Control (CNC) machining is a production technique that uses computer-controlled machines to accurately cut, shape and form parts. It can create complex geometries from materials such as metal (aluminum, steel, titanium), plastic or wood.The automotive industry integrates CNC machining to optimize performance, enhance safety, and reduce production costs. This is especially true now, as electric and hybrid vehicles become the standard.

Application Of CNC Machining Prototypes In The Automotive Industry The rapid prototyping capabilities of CNC machining have transformed how new automotive designs come to life. This technology allows engineers to quickly produce highly accurate models for early testing and optimization. In this blog, we explore the application of CNC machining in automotive parts manufacturing, including the types of CNC machines used, the benefits of using CNC machining, quality control measures in place, and Common materials for auto cnc machining. We also showcase some experience with automotive parts produced using CNC machining technology. Uncover 11 essential CNC machining applications driving efficiency and precision in the automotive industry. CNC machining is an important process in the automotive industry. Learn about the roles and applications of CNC automotive machining.

FREMONT, CA: The production of various vehicle parts using casting, turning, drilling, grinding, and milling is included in the use of CNC machines in the automotive industry. The technology has increased output levels in the industry by .

cnc machining in automotive industry

CNC Automotive machining is a production method that employs computer-controlled equipment to cut, mold, and automotive parts precisely. Also, this process can make intricate shapes out of materials like plastic or metal. In the automotive industry, CNC machined prototypes can include anything from headlight covers to engines. But CNC also helps to make end-use car parts. They include cylinder heads, starter motors, gearboxes, and one-off custom components for rare and vintage cars.

used sheet metal brakes

CNC machining has become integral to the automotive industry, offering several compelling advantages that enhance the manufacturing process. CNC benefits span from increased production speeds to heightened precision, each contributing significantly to the industry’s efficiency and product quality.Computer Numerical Control (CNC) machining is a production technique that uses computer-controlled machines to accurately cut, shape and form parts. It can create complex geometries from materials such as metal (aluminum, steel, titanium), plastic or wood.The automotive industry integrates CNC machining to optimize performance, enhance safety, and reduce production costs. This is especially true now, as electric and hybrid vehicles become the standard.

Application Of CNC Machining Prototypes In The Automotive Industry The rapid prototyping capabilities of CNC machining have transformed how new automotive designs come to life. This technology allows engineers to quickly produce highly accurate models for early testing and optimization. In this blog, we explore the application of CNC machining in automotive parts manufacturing, including the types of CNC machines used, the benefits of using CNC machining, quality control measures in place, and Common materials for auto cnc machining. We also showcase some experience with automotive parts produced using CNC machining technology. Uncover 11 essential CNC machining applications driving efficiency and precision in the automotive industry.

cnc machine automotive parts

CNC machining is an important process in the automotive industry. Learn about the roles and applications of CNC automotive machining.

cnc automotive parts

used sheet metal brake for sale

used steel trailer tongue box

Steel-cased ammo is metallic cartridge ammunition that uses steel shell casings instead of the more popular brass casings. While often associated with Russian ammunition, multiple countries have used steel-cased ammunition in the past for logistical and economic reasons.

+cnc +machine +for +automotive +industry|c&c automotive refinishing