production system for metal fabrication Traditionally, many metal fabrication job shops have relied on push production, with schedulers “pushing” jobs to the floor to maximize machine utilization. Many lean manufacturing experts opine about the merits of pull-based flow, where work completed at downstream workstations trigger orders to be processed upstream.

Top 10 Best Metal Fabricators in Murfreesboro, TN - November 2024 - Yelp - Lucas Industrial, Tennessee Tool Works, Mid-Tenn Metal Exchange Inc, Paulo, Stephen White Metal Design, .

0 · sheet metal manufacturing automation

1 · sheet metal fabrication fms

2 · metal manufacturing software reviews

3 · metal manufacturing software

4 · metal fabrication software

5 · hybrid metal manufacturing software

6 · fms sheet metal

7 · fabrication software for manufacturing

These clamps are specifically designed to assist in sheet metal seaming and bending! The welding clamp is made to hold pipes and other round material in place as you work. The sheet metal welding clamp holds flat metal sheets in place to get accurate welds. Each clamp is constructed of durable heat-treated steel for long-lasting use.

In our last blog, Metal Construction Industry 101 looked at the fundamentals along with the current and emerging trends. Continuing the conversation now with metal fabrication, another key fundamental process in the metal construction . Utilizing feature-based modeling also aids in maintaining precision, as it creates a history of operations that can be edited, ensuring measurements are consistent and traceable.. CAD also simplifies the .

Planned. Tracked. Automated. Analysed. Optimised. Understood. LYNQ is reinventing MES (manufacturing execution system) software tailored to the Metal Fabrication industry to manage and optimise manufacturing operations and .Metal fabrication is a very broadly interpreted activity, and we provide a broad range of metal fabrication services. We specialize in contract production quantities of machined and fabricated metal parts to our clients. Our team will work with you to ensure your project is delivered to your specifications, on time, the first time.

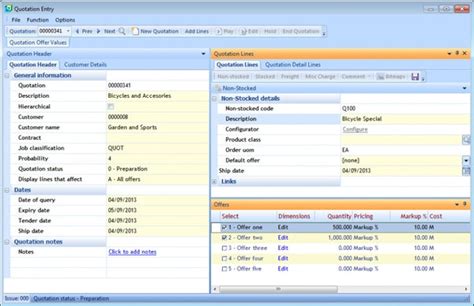

Metal fabrication ERP makes production planning easy through supply chain visibility, inventory management, production scheduling, and more. . In this dynamic environment, metal fabrication ERP systems emerge as indispensable tools, offering tailored solutions that streamline and optimize every aspect of production planning. . Traditionally, many metal fabrication job shops have relied on push production, with schedulers “pushing” jobs to the floor to maximize machine utilization. Many lean manufacturing experts opine about the merits of pull-based flow, where work completed at downstream workstations trigger orders to be processed upstream.Metal fabrication ERP - industry built software for manufacturers. SYSPRO offers choice and flexibility with on-premise and cloud solutions . SYSPRO, you’ll have real-time control and visibility over your manufacturing operations. And it’s not just about production; our system integrates seamlessly with key back-office functions like . Most North American metal fabrication occurs in high-product-mix environments. On a given day, a fabricator could be managing dozens or even hundreds of different jobs across the shop floor. That makes thinking broadly easier said than done, but in the quest for true productivity improvements—that is, more products shipped out the door in .

For metal fabricators, this includes storage expenses, insurance, and depreciation of materials. By optimizing your inventory levels, you can reduce these costs significantly. Production Efficiency: Having the right materials readily available when needed ensures that production processes flow smoothly. It prevents unnecessary downtime, delays .

A metal fabrication plant may have a cutting department, a drilling department, and a polishing department. . Which of the following characteristics are essential for a JIT system to function properly? (Select three answers)-Suppliers must be located relatively near the production facility.-Suppliers must be extremely reliable.

How does EVS Metal use lean processes in their precision sheet metal fabrication facilities? As a lean metal fabrication and manufacturing shop, we use the tools and systems that form the framework of the lean philosophy to systemically streamline our work processes, ultimately leading to greater efficiency, decreased costs and faster production times.The Top ERP Systems for: Metal and Steel Fabrication, Job Shop / Machine Shop, Barcoding, Cloud ERP A comprehensive comparison of the best ERP systems matching your selected requirements. Easily compare key features, pricing, and functionality to make a well-informed decision for your business.Find the top Metal Fabrication software of 2024 on Capterra. Based on millions of verified user reviews - compare and filter for whats important to you to find the best tools for your needs. . Cloud based ERP system for the smaller manufacturing Co. Simple to use, affordable and a simple 30 day rolling contract. . Manage your production . The central control system and the customer production management system exchange information, allowing for automatic scheduling of sheet metal products based on the order quantity. This results in the formulation of production and processing plans, and the automatic programming of these plans is then pushed to the processing equipment.

SYSPRO BOM Simplify complex processes and gain transparency with a clear list of materials and quantities for inventory management and purchasing.. Metal fabricators can track actual production costs against accurate expected costs, . Metal Fabrication Categories. Let’s explore the four main categories of metal fabrication. Structural Fabrication. Structural fabrication is a specialized sub-category of metal fabrication that focuses on the creation of large-scale structural components and assemblies used in various industries, including construction, manufacturing, and infrastructure development.The Top ERP Systems for: Metal and Steel Fabrication, Job Shop / Machine Shop, 1 to 500 Million, On Premise A comprehensive comparison of the best ERP systems matching your selected requirements. Easily compare key features, pricing, and functionality to make a well-informed decision for your business.[Profile cutting up to 10kW, with automated load/unload systems for high volume production.] Metal Forming [Press Brakes up to 500 tons, all equipped with CNC back gauges for speed and consistency.]

Industrial Finishing Systems Production Systems, Inc. was founded in 1972 by William A. Ball in High Point, North Carolina. Mechanical installation services of ovens and spray booths as provided by Binks and DeVilbiss was typical business throughout the 70’s and 80’s. Capabilities expanded with sheet metal and It also takes times to develop, test, tweak, retest, tweak again, and qualify a new 3D printer—especially one that breaks as much new ground as DM’s Production System.The company claims its new machine is the “world’s fastest metal printer . and the first and only metal 3D printing system for mass production that [can] compete with . Investments in manufacturing automation, inspection, and other process-related technology should be matched with investments in material handling, parts tracking, and the IT systems in use all over your factory. These are the foundational, essential, industrial, and production engineering details that are at the core of any production system!

Scheduling by constraint in metal fabrication How the drum-buffer-rope system may simplify job shop management. By Bob Sproull; . DBR is that every process or system has a constraint within it that controls the throughput rate of the process or system, and that production schedules should be developed based on the output of the system .Production Metal Fabrication. LASER-CUTTING, FORMING, WELDING, FINISHING AND MORE. FULL-SERVICE FABRICATION. Your customers expect the best from your products. That’s why you can’t buy fabricated sheet metal parts from just anywhere. You need to source with someone who shares the same high standards for fit, function and finish that you do.Eziil is a state-of-the-art metal fabrication software designed to give you a real-time overview of the manufacturing process. It aims to improve manufacturing processes efficiency, accuracy, and productivity. It has advanced solutions for all primary metal fabrication processes like project management, bill of materials, bill of operations, drawing management, procurement, .

Metal fabricators can track actual production costs against accurate expected costs, enabling informed decisions for profitability optimization. The what-if costing capabilities allow for the simulation of different production scenarios, helping you . An ERP software for metal fabrication can provide many benefits. It can help with production and inventory management, which in turn will lead to a better utilization of resources and a more profitable business. A metal fabricator who installs modern ERP software correctly can increase production output and without having to hire more staff .

sheet metal manufacturing automation

sheet metal fabrication fms

As a single-source solutions provider, we’re capable of taking your metal furniture projects from conception to completion. Whether your steel furniture fabrication project involves creating a prototype or you’re ready for volume production, we offer full-service metal furniture manufacturing across Pennsylvania and beyond. Get a Quote

metal manufacturing software reviews

metal manufacturing software

metal fabrication software

Find Steel Welded Seams garage cabinets at Lowe's today. Shop garage cabinets and a variety of storage & organization products online at Lowes.com.

production system for metal fabrication|sheet metal fabrication fms