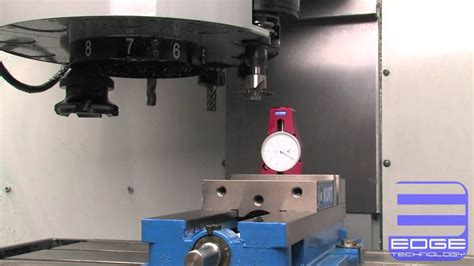

tool setting cnc machine A tool setter is a sensor used to measure the length of tools on CNC machine . Aluminum 6061, a grade of aluminum, sets the standard for strong, lightweight materials capable of standing up to corrosion and degradation. With decades of experience handling this material, D.W. Ram is a trusted provider of aluminum 6061 machined parts.

0 · tool setter for cnc mill

1 · cnc tool set up sheet

2 · cnc setup sheet pdf

3 · cnc mill setup sheet

4 · cnc machining setup sheet

5 · cnc machine setup checklist

6 · cnc lathe setup sheet template

7 · cnc lathe setup sheet

Large selection of metal detectors for hobby and security use from top manufacturers. Detect gold, silver, coins or valuable relics. Free shipping on all orders.For XLT, DFX, MXT, ETC. 100K Sens./ On-Off Switch. Following are accessories and replacement parts for Deus detectors and accessories for Garretts.

Learn how to set the tool position and location in CNC machining, and the types of tools and instruments used for tool setting. Compare the advantages and disadvantages of different tool setting methods, such as trial cutting, feeler gauge, edge finder, and special tool .

cnc machine manufacturer in gujarat

A tool setter is a sensor used to measure the length of tools on CNC machine . A tool setter is a sensor used to measure the length of tools on CNC machine tools. By automatically measuring the tool length with micron accuracy and feeding it back to the Numerical Control (NC), it compensates . These settings include the spindle speed, feed rate, depth of cut, and cutting tool paths. Each parameter must be carefully adjusted based on the material being machined, the type of tool used, and the specific requirements .

Learn how to master tool setting for CNC machines and optimize your production process. Sigma Technik Limited offers on-demand CNC machining services for various applications and . These systems are often standalone units that can be used independently of the CNC machine to prepare tools for use. Integrated Tool Setting Systems: Some CNC machines come with integrated tool setting . Genmitsu Upgraded CNC Router Photoelectric Z-Axis Tool Setting Touch Probe with indicators, Compatible with Genmitsu 3018-PROVer V2, 4040-PRO, 4040 Reno, 3020-PRO MAX V2 CNC machine: Amazon.com: Tools & .

This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. . Cutting Tools: CNC lathe machines require various cutting tools to .

Make high-precision machining easy with our range of tool setting arms for CNC machines. Designed to take tool setting to the next level, our innovative products set the standard for efficiency and accuracy. Precision-engineered tool setting arms.

As a premium laser tool setter for CNC machines, NC4 systems are a beneficial part of any manufacturer's in-process control procedures. . By implementing in-process, automated tool setting, tight tolerances and high-quality finishes can easily be attained. Laser tool setters deliver reliable, non-contact, high-speed measurements with sub .

Make high-precision machining easy with our range of tool setting arms for CNC machines. Designed to take tool setting to the next level, our innovative products set the standard for efficiency and accuracy. Precision-engineered tool setting arms. However when I watch videos of setting tool offsets for a cnc milling machine they all show how to set the tool offsets on finish (sides/top) of parts. My question is how to allow for Roughing? If you put a part that is from stock material in a machine and touch off your tools how will you know the finish surface for your finishing tools . 【Description】The tool setting instrument is a special tool setting instrument for the engraving machine machining center machine. The output signal of the tool setting instrument is received by the numerical control system and then the tool length setting, tool wear detection and tool breakage are detected by the program control.

– G-Code snippet that uses G10 to load Tool Info into the machine’s tool table, for example if you’re using offline tool setting. – Digital Photos or CAD drawings of the cutter and toolholder. – Enough other information so that if we break an insert or damage a tool we can use the information to get back up and running ASAP. To illustrate the variation in zero point setting among different machines and software, let's consider two popular CNC lathe models: Machine A and Machine B. Machine A uses a proprietary software that requires the operator to manually position the tool at the desired zero point and enter the coordinates using the control panel.

Z Axis tool length setter is an assistant tool for setting tool length on CNC machines. This Z axis tool setter's preset height is 50.00±0.005mm. Features: 1. Suitable for CNC lathe or milling machine; 2. Large measuring surface, easy use. 3. Small spring force to protect milling or drilling bits from being broken 4. Setting can be easily done .Amazon.com: cnc tool setter. . Aluminum Alloy Z Axis Probe Tool Touch Sensor Setting Gauge for CNC Engraving Machine (Blue) .86 $ 51. 86. FREE delivery Sun, May 12 . Or fastest delivery Wed, May 8 . Only 7 left in stock - order soon. More Buying Choices .02 (3 . The tool setting instrument is suitable for the engraving machine machining center machine. The output signal of the tool setting instrument is received by the numerical control system and then the tool length setting, tool wear detection and tool breakage are detected by the program control. Note: Package List: 1 x Automatic Tool Setting Gauge . The tool setting mode of analog tool angle is adopted, which has the advantages of low cost and convenient operation. It is applied to the calibration of ultrasonic CNC milling straight edge tools in an aircraft manufacturer. In the machining program, just input the corresponding tool number, and the system will automatically complete the reference .

Load G-code into the CNC machine: Transfer the G-code to the CNC machine, ensuring it is correctly formatted and free of errors. Set Tool Offset. Measure tool length: Use a tool setter to measure the tool length .

Use a Perfect Zero SwissSetter camera and tabletop apparatus to preset cutting tools at a certain length for hassle-free install on Swiss or other CNC machines. Theory 168 View Products

tool setter for cnc mill

Learn the process of finding and storing a Work Offset on a 3-Axis CNC Mill.A quick release lever allows the HPA to be removed from the machine’s working envelope during metal cutting and stored on a stand. The stand may be conveniently located on top of the CNC machine. Specifications: Tool setting times up to 90% faster, than traditional methods. Offset calculation automatic and reliable.Make high-precision machining easy with our range of tool setting arms for CNC machines. Designed to take tool setting to the next level, our innovative products set the standard for efficiency and accuracy. Precision-engineered tool setting arms.

Milling Tools CNC Z-Axis Tool Setting Touch Plate Probe Mach3 Router Mill ; Effective Surface Diameter: 30mm. . Package include: 1x CNC Router Engraving Machine Tool Specification Diameter:(Approx.) 40mm Height:(Approx.) 20mm Effective surface of the knife: . With a mouse click, CNC machines will automatically return to a predefined position, allowing you to easily change and calibrate your tools. Z-Axis tool setting touch probe works with Mach3, Grblcontrol(Candle) Makes setting tool height a breeze, no more using the paper. Auto-Check setting probe. › See more product detailsFinally, trial cutting is needed. Statistics show that the pure maneuvering time of a workpiece only accounts for 55% of the total time, and the auxiliary time such as clamping and tool setting accounts for 45%. Therefore, the tool setting used shows great advantages. Principle of contact tool setting: The core component of the tool setting .Manufacturer of tool setters for machining centers, tool setting arms for lathes and precision sensors. CNC tool setters, tool setter principles and functions, steps to solve tool setting problems in machining centers, contact Ballsum for tool setting technology.

In the field of applications where non-contact tool setters are possible , Mida Laser P is a system capable of measuring tools of any size on machining centers and or milling machines. Utilizing laser technology, Mida Laser P is able to provide extremely precise values of length and diameter even for small tools (less than one millimeter). From the point of view of measurement speed, .

Enter Z0 (Z-axis tool setting completed). At this time, the roughing thread tool setting ends. According to this method, the thread finishing is performed again, and the operation process is exactly the same as the rough turning tool setting method. In this way, random snapping will not occur during the cutting process. BTER CNC Automatic Tool Sensor Gauge, DC 24V Normally Closed CNC Z Axis Tool Setter, High Accuracy Aluminum Alloy Z Axis Probe Tool Touch Sensor Setting Gauge for CNC Router Engraving Machine dummy Genmitsu Upgraded CNC Router Photoelectric Z-Axis Tool Setting Touch Probe with indicators, Compatible with Genmitsu 3018-PROVer V2, 4040 .

CNC Z-Axis router mill touch plate tool setting probe new milling hot kit. CNC router engraving machine tool setting auto-Check instrument 1.38inch ; CNC router mill: Z-Axis tool setting touch plate works ; Effective surface of the blade: approx. 25mm /0.98inch (diameter) Size: approx. 3.5 x 2cm/ 1.38 x 0.79inch (D x H) › See more product details

cnc tool set up sheet

Sigma's weatherproof round extension ring increases the capacity of a weatherproof box. The rugged, die-cast construction prevents moisture penetration making the boxes suitable for wet, damp or dry locations. Extension rings are powder coated for corrosion resistance and include closure plugs, hardware and gasket.

tool setting cnc machine|cnc tool set up sheet