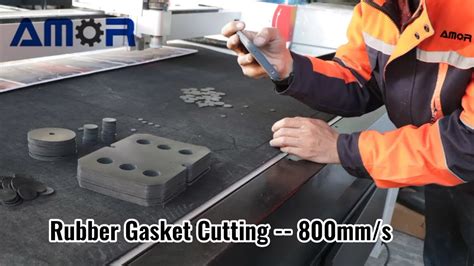

cnc gasket cutter machine CNC gasket cutting machine is an industrial automatic knife cutter to cut asbestos gaskets, rubber gaskets, non-asbestos plate gaskets, aramid gaskets, cylinder gaskets, rubber gaskets, cotton rubber sheet gaskets, silicone gaskets. Typically, you should use warm metals (like brass, nickel and copper) with warm hues (like whites, beiges, browns and taupes) and cool metals (such as chrome and silver) with cool hues (such as blues, greens and grays). .

0 · rubber gasket cutting machine

1 · manual gasket cutting machine

2 · laser gasket cutting machine

3 · laser gasket cutter

4 · industrial gasket cutter

5 · gasket die cutting machine

6 · desktop cnc gasket cutting machine

7 · automatic gasket cutting machine

CNC (Computer Numerical Control) machines rely on specialized software to control and automate their operations. This software acts as the brain behind the intricate movements and actions of CNC machines. By utilizing a combination of hardware and software, CNC machines can precisely fabricate door hardware components with unmatched accuracy.From appliances and light fixtures to desk tools, chairs, and utensils, metal is the stabilizing element that makes all of today’s .

rubber gasket cutting machine

Gasket cutting machine can fulfill all of your needs for gasket form, from simple to complicated, from prototype to mass production, and from a design or CAD file. The choice of gasket material is critical to maintaining precise sealing, . AMOR CNC gasket cutting machine adopts a high-frequency pneumatic oscillation tool cutting gasket. Reasonable and advanced mechanical structure design, combined with .Experience fast, precise, and stable gasket cutting with AMOR's high-frequency oscillating technology and specialized software. Ideal for various materials including PTFE and asbestos-free sheets. AMOR CNC tackles industry issues . A CNC oscillating knife gasket cutting machine is a powerful tool for meeting modern industry demands for precision and customization. By understanding its tools, .

CNC gasket cutting machine is an industrial automatic knife cutter to cut asbestos gaskets, rubber gaskets, non-asbestos plate gaskets, aramid gaskets, cylinder gaskets, rubber gaskets, cotton rubber sheet gaskets, silicone gaskets.Gasket cutting machine can fulfill all of your needs for gasket form, from simple to complicated, from prototype to mass production, and from a design or CAD file. The choice of gasket material is critical to maintaining precise sealing, depending on .

linear chandelier standard junction box

AMOR CNC gasket cutting machine adopts a high-frequency pneumatic oscillation tool cutting gasket. Reasonable and advanced mechanical structure design, combined with professional sealing industry intelligent processing software, to meet the high precision, high speed and high-quality cutting of sealing gasket.Experience fast, precise, and stable gasket cutting with AMOR's high-frequency oscillating technology and specialized software. Ideal for various materials including PTFE and asbestos-free sheets. AMOR CNC tackles industry issues like labor age, inefficiency, and waste, simplifying complex cuts and streamlining operations.A CNC Gasket Cutting Machine is a computer-controlled cutting device that employs specialized software and precision machinery to fabricate gaskets of various shapes and sizes. Unlike conventional methods, where gaskets are hand-cut using templates, CNC machines follow digital designs with unparalleled accuracy. A CNC oscillating knife gasket cutting machine is a powerful tool for meeting modern industry demands for precision and customization. By understanding its tools, operation, and maintenance, you can maximize efficiency and minimize downtime.

The CNC Industrial Oscillating Knife Gasket Cutting Machine uses a high-speed oscillating blade to cut gasket material. The oscillating motion of the cutter enables it to precisely cut thicker or harder gasket materials such as rubber, silicone or PTFE.All-in-One Cutting: 6 functions from cutting to kiss cutting. Nest Fast & Save: Auto-nesting in under 1 minute saves 10% material. Rapid Performance: At 1500mm/s, replaces 2-3 workers. A variety of intelligent software: identification, positioning, nesting.

Multi-tool combination cutting, computer motion control.Diversification, to meet the cutting needs of customers, to maximize the practical performance of the equipment.As a technical engineer at AMOR CNC, I'll guide you through selecting the right CNC gasket cutting machine, focusing on its working principle, processing capacity, usage costs, tools, and installation requirements. CNC gasket cutting machine is an industrial automatic knife cutter to cut asbestos gaskets, rubber gaskets, non-asbestos plate gaskets, aramid gaskets, cylinder gaskets, rubber gaskets, cotton rubber sheet gaskets, silicone gaskets.Gasket cutting machine can fulfill all of your needs for gasket form, from simple to complicated, from prototype to mass production, and from a design or CAD file. The choice of gasket material is critical to maintaining precise sealing, depending on .

AMOR CNC gasket cutting machine adopts a high-frequency pneumatic oscillation tool cutting gasket. Reasonable and advanced mechanical structure design, combined with professional sealing industry intelligent processing software, to meet the high precision, high speed and high-quality cutting of sealing gasket.

Experience fast, precise, and stable gasket cutting with AMOR's high-frequency oscillating technology and specialized software. Ideal for various materials including PTFE and asbestos-free sheets. AMOR CNC tackles industry issues like labor age, inefficiency, and waste, simplifying complex cuts and streamlining operations.

A CNC Gasket Cutting Machine is a computer-controlled cutting device that employs specialized software and precision machinery to fabricate gaskets of various shapes and sizes. Unlike conventional methods, where gaskets are hand-cut using templates, CNC machines follow digital designs with unparalleled accuracy. A CNC oscillating knife gasket cutting machine is a powerful tool for meeting modern industry demands for precision and customization. By understanding its tools, operation, and maintenance, you can maximize efficiency and minimize downtime.The CNC Industrial Oscillating Knife Gasket Cutting Machine uses a high-speed oscillating blade to cut gasket material. The oscillating motion of the cutter enables it to precisely cut thicker or harder gasket materials such as rubber, silicone or PTFE.

manual gasket cutting machine

All-in-One Cutting: 6 functions from cutting to kiss cutting. Nest Fast & Save: Auto-nesting in under 1 minute saves 10% material. Rapid Performance: At 1500mm/s, replaces 2-3 workers. A variety of intelligent software: identification, positioning, nesting.Multi-tool combination cutting, computer motion control.Diversification, to meet the cutting needs of customers, to maximize the practical performance of the equipment.

laser gasket cutting machine

laser gasket cutter

Metal coping, in skateboarding terms, refers to the metal tube at the edge of transition ramps, halfpipes, or in a custom grind box. These are common places where metal copings are used, but you’ll notice metal coping .

cnc gasket cutter machine|desktop cnc gasket cutting machine