best gauge sheet metal for jewelry The easy answer, and the one Tracy is looking for, is that 22 gauge silver is the workhorse of most sheet metal jewelry. If not that then I’d think most people will usually go . $21.33

0 · working silver metal gauge

1 · jewelry gauge chart

2 · best sheet metal gauges for jewelry

3 · best sheet metal gauge

4 · best gauge for jewelry making

5 · 18 gauge sheet metal jewelry

6 · 18 gauge sheet metal bracelet

7 · 18 gauge sheet metal

Find Bracket shelf Floating wall mounted shelving at Lowe's today. Shop wall mounted shelving and a variety of storage & organization products online at Lowes.com.

working silver metal gauge

Choosing the right gauge is essential to make unique jewelry pieces that are visually appealing, durable, and configured to the desired purpose. In this guide, we'll explain . This chart gives you the recommended minimum metal gauge for common jewelry items, including bezels, bracelets, ear wires, rings and more. If you’re working with brass or .

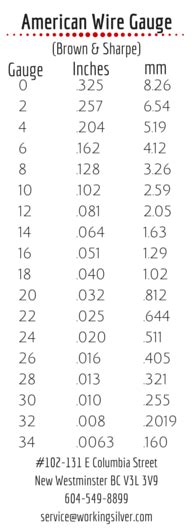

Below is a handy reference chart with the most common metal gauges and their equivalent measurements, both in metric and imperial. When picking an appropriate gauge for a project the first thing to consider is what are .

metal fabricator ca

It can also indicate which type of metal sheet is right for your jewelry-making project with gauge, hardness, recommended uses and other information. Lightweight, double-sided anodized aluminum sheet is malleable and easy to . The easy answer, and the one Tracy is looking for, is that 22 gauge silver is the workhorse of most sheet metal jewelry. If not that then I’d think most people will usually go . I recommend a newbie purchase some 24 gauge sheet before moving to thicker metal, just to cut down on practice costs without sacrificing strength for most cabochons. In .,149.10

.99.99.99.96

Explore the comprehensive guide to sheet metal gauge charts. Master the art of selecting the perfect metal thickness for your fabrication projectsWhen crafting rings, the gauge (thickness) of the sheet metal you choose is crucial for both the design and durability of the piece. A commonly selected thickness is between 18 (1.0mm) to 24 gauge (0.5mm), with 18-gauge sheet .

Copper Sheet Metal: 22-gauge copper sheet metal not only etches deeply but it also possesses good durability and longevity. Nickel Silver Sheet Metal: 22- or 24-gauge nickel silver can be etched with great results.

WHICH GAUGE SHEET TO BUY? Sheet metal is going to be one of your most commonly used forms of silver when making jewelry. Sheet is available for purchase from jewelry supply companies here in the United States from 8g (3.2mm) to .

Choosing the right gauge is essential to make unique jewelry pieces that are visually appealing, durable, and configured to the desired purpose. In this guide, we'll explain the ideal sheet metal gauges for stone mounting, bracelet forming, and pendant backing for successful jewelry making. This chart gives you the recommended minimum metal gauge for common jewelry items, including bezels, bracelets, ear wires, rings and more. If you’re working with brass or bronze, follow the recommendations for sterling silver; for copper, follow fine silver. Below is a handy reference chart with the most common metal gauges and their equivalent measurements, both in metric and imperial. When picking an appropriate gauge for a project the first thing to consider is what are you making.It can also indicate which type of metal sheet is right for your jewelry-making project with gauge, hardness, recommended uses and other information. Lightweight, double-sided anodized aluminum sheet is malleable and easy to work with for creating sheet metal jewelry.

The easy answer, and the one Tracy is looking for, is that 22 gauge silver is the workhorse of most sheet metal jewelry. If not that then I’d think most people will usually go thinner rather than thicker most of the time -unless the whole piece is that much larger or needs real strength and weight, like a belt buckle. I recommend a newbie purchase some 24 gauge sheet before moving to thicker metal, just to cut down on practice costs without sacrificing strength for most cabochons. In general, you can use the following gauges as described: 18-20 gauge- Flush setting small stones, heavy backplates, structural elements, texturing; 20-22-Backplates, heavier . Explore the comprehensive guide to sheet metal gauge charts. Master the art of selecting the perfect metal thickness for your fabrication projects

When crafting rings, the gauge (thickness) of the sheet metal you choose is crucial for both the design and durability of the piece. A commonly selected thickness is between 18 (1.0mm) to 24 gauge (0.5mm), with 18-gauge sheet metal offering robustness for everyday wear while still allowing for detailed workmanship. Copper Sheet Metal: 22-gauge copper sheet metal not only etches deeply but it also possesses good durability and longevity. Nickel Silver Sheet Metal: 22- or 24-gauge nickel silver can be etched with great results.

WHICH GAUGE SHEET TO BUY? Sheet metal is going to be one of your most commonly used forms of silver when making jewelry. Sheet is available for purchase from jewelry supply companies here in the United States from 8g (3.2mm) to . Choosing the right gauge is essential to make unique jewelry pieces that are visually appealing, durable, and configured to the desired purpose. In this guide, we'll explain the ideal sheet metal gauges for stone mounting, bracelet forming, and pendant backing for successful jewelry making.

This chart gives you the recommended minimum metal gauge for common jewelry items, including bezels, bracelets, ear wires, rings and more. If you’re working with brass or bronze, follow the recommendations for sterling silver; for copper, follow fine silver. Below is a handy reference chart with the most common metal gauges and their equivalent measurements, both in metric and imperial. When picking an appropriate gauge for a project the first thing to consider is what are you making.

It can also indicate which type of metal sheet is right for your jewelry-making project with gauge, hardness, recommended uses and other information. Lightweight, double-sided anodized aluminum sheet is malleable and easy to work with for creating sheet metal jewelry.

The easy answer, and the one Tracy is looking for, is that 22 gauge silver is the workhorse of most sheet metal jewelry. If not that then I’d think most people will usually go thinner rather than thicker most of the time -unless the whole piece is that much larger or needs real strength and weight, like a belt buckle. I recommend a newbie purchase some 24 gauge sheet before moving to thicker metal, just to cut down on practice costs without sacrificing strength for most cabochons. In general, you can use the following gauges as described: 18-20 gauge- Flush setting small stones, heavy backplates, structural elements, texturing; 20-22-Backplates, heavier . Explore the comprehensive guide to sheet metal gauge charts. Master the art of selecting the perfect metal thickness for your fabrication projectsWhen crafting rings, the gauge (thickness) of the sheet metal you choose is crucial for both the design and durability of the piece. A commonly selected thickness is between 18 (1.0mm) to 24 gauge (0.5mm), with 18-gauge sheet metal offering robustness for everyday wear while still allowing for detailed workmanship.

metal fabricator london

$79.99

best gauge sheet metal for jewelry|working silver metal gauge