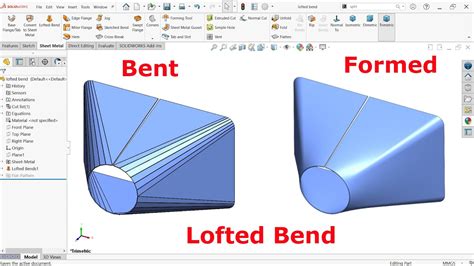

creating sheet metal parts with conical faces To create a sheet metal part with conical faces: Any adjacent planar and conical . I would recommend switching the transformer to an EN-2460-R2 by WAC Lighting. It has a 24v AC output and a 1w min load. They also carry an LED puck (HR-LED87) and an edge-lit version (HR-LED90) that are both pretty nice.

0 · solidworks sheet metal conical

1 · solidworks sheet metal bends

2 · sheet metal with conical faces

An electrical junction box is a safety box used to cover wires that have been joined in a single electrical unit. An electrical junction box can either be made of metal or plastic. To save on costs, plastic junction boxes offer a cheaper alternative to metal.illustrations on how to wire switches and lights using junction box

solidworks sheet metal conical

Select a planar face tangent to the conical face as the fixed face. The fixed edge remains in place when the part is flattened. The name of the edge is displayed in the Fixed Face or Edge box. .To create a sheet metal part with conical faces: Create a thin feature part with .

solidworks sheet metal bends

To create a sheet metal part with conical faces: Any adjacent planar and conical .

Parts with conical faces can also be made of sheet metal. To create a sheet metal .

To create a sheet metal part with conical faces: Create a thin feature part with one or more conical faces: Any adjacent planar and conical faces must be tangent.

To create a sheet metal part with conical faces: Any adjacent planar and conical faces must be tangent. At least one end face of any conical face must have at least one linear edge. Click .

Parts with conical faces can also be made of sheet metal. To create a sheet metal part with conical Create sheet metal parts by converting existing parts, extruding sketch curves (including arcs and splines to create rolled sheet metal), or thickening faces or sketches.

This video will show you a simple process for making conical sheet metal components, that will unfold, in Autodesk Fusion 360

sheet metal with conical faces

Autodesk Fusion 360 does not have a specific command that will allow the creation of conical sheet metal components, but with a little creativity, the process is easy! The first step is to create a constrained sketch of the . The steps to make an unfolding diagram are as follows. 1. Draw the main view and fill in the top truncation to form a complete cone. 2. Make a cone surface line by dividing the .The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, .The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height .

Select a planar face tangent to the conical face as the fixed face. The fixed edge remains in place when the part is flattened. The name of the edge is displayed in the Fixed Face or Edge box. Set the Bend Radius. Select Ignore beveled faces to exclude chamfers from being converted into sheet metal bends.To create a sheet metal part with conical faces: Create a thin feature part with one or more conical faces: Any adjacent planar and conical faces must be tangent.To create a sheet metal part with conical faces: Any adjacent planar and conical faces must be tangent. At least one end face of any conical face must have at least one linear edge. Click Insert Bends or Insert > Sheet Metal > Bends. The Bends PropertyManager appears. Select a linear edge on an end face of a conical face as the fixed edge.

Parts with conical faces can also be made of sheet metal. To create a sheet metal part with conical

Create sheet metal parts by converting existing parts, extruding sketch curves (including arcs and splines to create rolled sheet metal), or thickening faces or sketches.

This video will show you a simple process for making conical sheet metal components, that will unfold, in Autodesk Fusion 360 Autodesk Fusion 360 does not have a specific command that will allow the creation of conical sheet metal components, but with a little creativity, the process is easy! The first step is to create a constrained sketch of the desired conical component wall. The steps to make an unfolding diagram are as follows. 1. Draw the main view and fill in the top truncation to form a complete cone. 2. Make a cone surface line by dividing the base circle into a number of equal parts, in this case 12 equal parts, to obtain 1, 2, ., 7 points, from these points to draw a vertical line upwards, and intersect the base circle orthographic .The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, from aerospace to automotive.

The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height of the cone.Select a planar face tangent to the conical face as the fixed face. The fixed edge remains in place when the part is flattened. The name of the edge is displayed in the Fixed Face or Edge box. Set the Bend Radius. Select Ignore beveled faces to exclude chamfers from being converted into sheet metal bends.

To create a sheet metal part with conical faces: Create a thin feature part with one or more conical faces: Any adjacent planar and conical faces must be tangent.To create a sheet metal part with conical faces: Any adjacent planar and conical faces must be tangent. At least one end face of any conical face must have at least one linear edge. Click Insert Bends or Insert > Sheet Metal > Bends. The Bends PropertyManager appears. Select a linear edge on an end face of a conical face as the fixed edge.Parts with conical faces can also be made of sheet metal. To create a sheet metal part with conical Create sheet metal parts by converting existing parts, extruding sketch curves (including arcs and splines to create rolled sheet metal), or thickening faces or sketches.

tapering parts cnc machine

This video will show you a simple process for making conical sheet metal components, that will unfold, in Autodesk Fusion 360

Autodesk Fusion 360 does not have a specific command that will allow the creation of conical sheet metal components, but with a little creativity, the process is easy! The first step is to create a constrained sketch of the desired conical component wall. The steps to make an unfolding diagram are as follows. 1. Draw the main view and fill in the top truncation to form a complete cone. 2. Make a cone surface line by dividing the base circle into a number of equal parts, in this case 12 equal parts, to obtain 1, 2, ., 7 points, from these points to draw a vertical line upwards, and intersect the base circle orthographic .

The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, from aerospace to automotive.

Pull the wires you need to connect into the electrical junction boxes through the holes you’ve made. Allow six inches of wire to hang out of the box and then cut off any excess wire with your knife. You want ample wire so you can work easily, but not an excess.

creating sheet metal parts with conical faces|solidworks sheet metal bends