cnc machine for gaskets Professional intelligent nesting software for gaskets, without CAD drawing, just input data to get cutting graphics. Support multiple nesting modes – custom plate size, residual material nesting, common edge nesting, etc., to improve the utilization of materials. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

0 · rubber gasket cutting machine

1 · manual gasket cutting machine

2 · laser gasket cutting machine

3 · industrial gasket cutter

4 · gasket manufacturing machine

5 · gasket die cutting machine

6 · cnc gasket cutter machine

7 · automatic gasket cutting machine

$45.99

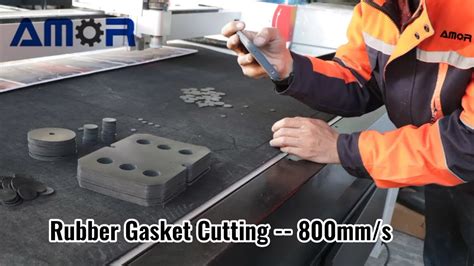

Gasket cutting machine does not require a custom-made die. It is built around a CNC system that includes a programmable, oscillating knife blade cutter on a bed-type table. High-powered LED lights direct the design directly onto the . Professional intelligent nesting software for gaskets, without CAD drawing, just input data to get cutting graphics. Support multiple nesting modes – custom plate size, . Automatic CNC gasket cutting machine features with high precision and efficiency, which is suitable for the manufacturing of small batch gaskets. The automatic gasket cutter can cut any shape with smooth cutting edge, no pollution, no .

Gasket cutting machine does not require a custom-made die. It is built around a CNC system that includes a programmable, oscillating knife blade cutter on a bed-type table. High-powered LED lights direct the design directly onto the cutting table. Professional intelligent nesting software for gaskets, without CAD drawing, just input data to get cutting graphics. Support multiple nesting modes – custom plate size, residual material nesting, common edge nesting, etc., to improve the utilization of materials.CNC oscillating knife gasket cutting machines use a high-speed, oscillating knife blade to cut gasket materials. The vibrating motion of the knife allows it to precisely cut through thicker or harder gasket materials, such as rubber, silicone, or PTFE.

The CNC gasket cutting machine follows the design path and moves the oscillating knife across the rubber material with high precision and speed. As the knife oscillates, it creates a back-and-forth motion, effectively cutting through the rubber.Our digital cnc oscillating knife cutting machine in the sealing industry is mainly used for automatic intelligent cutting of flexible sealing materials, including non asbestos sheet, asbestos rubber sheet, graphite composite sheet, rubber, PTFE, etc.

A CNC gasket cutting machine is a high-precision machine that uses Computer Numeric Control (CNC) technology to automate the cutting process. The benefits of using a CNC gasket-cutting machine include higher accuracy, increased production speed, .The gasket cutting machine is a CNC knife cutter machine that automatically cuts according to CAD drawings without the need for a die cutter. With professional typesetting software, the CNC gasket cutter machine can improve material utilization and reduce production costs.I will explain to you in detail how to choose a correct CNC gasket cutting machine from the aspects of the machine's working principle, processing capacity, usage cost, different tools, installation requirements, etc., and share with you 2 successful customer cases.

rubber gasket cutting machine

CNC laser cutter with CCD camera visual recognition system for accurate cutting gaskets & seals made of rubber, neoprene, silicone, graphite, CNAF, PTFE. Automatic CNC gasket cutting machine features with high precision and efficiency, which is suitable for the manufacturing of small batch gaskets. The automatic gasket cutter can cut any shape with smooth cutting edge, no pollution, no .Gasket cutting machine does not require a custom-made die. It is built around a CNC system that includes a programmable, oscillating knife blade cutter on a bed-type table. High-powered LED lights direct the design directly onto the cutting table. Professional intelligent nesting software for gaskets, without CAD drawing, just input data to get cutting graphics. Support multiple nesting modes – custom plate size, residual material nesting, common edge nesting, etc., to improve the utilization of materials.

CNC oscillating knife gasket cutting machines use a high-speed, oscillating knife blade to cut gasket materials. The vibrating motion of the knife allows it to precisely cut through thicker or harder gasket materials, such as rubber, silicone, or PTFE. The CNC gasket cutting machine follows the design path and moves the oscillating knife across the rubber material with high precision and speed. As the knife oscillates, it creates a back-and-forth motion, effectively cutting through the rubber.

Our digital cnc oscillating knife cutting machine in the sealing industry is mainly used for automatic intelligent cutting of flexible sealing materials, including non asbestos sheet, asbestos rubber sheet, graphite composite sheet, rubber, PTFE, etc.

A CNC gasket cutting machine is a high-precision machine that uses Computer Numeric Control (CNC) technology to automate the cutting process. The benefits of using a CNC gasket-cutting machine include higher accuracy, increased production speed, .The gasket cutting machine is a CNC knife cutter machine that automatically cuts according to CAD drawings without the need for a die cutter. With professional typesetting software, the CNC gasket cutter machine can improve material utilization and reduce production costs.I will explain to you in detail how to choose a correct CNC gasket cutting machine from the aspects of the machine's working principle, processing capacity, usage cost, different tools, installation requirements, etc., and share with you 2 successful customer cases.

manual gasket cutting machine

scx10 metal chassis

seam joint in sheet metal

$36.17

cnc machine for gaskets|industrial gasket cutter