drill ground hole electrical box Drill Holes in the Framing. Bore 3/4-inch holes through the framing members about 8 inches above the boxes. Pro tip: Center the bit on the stud, brace the drill and apply pressure with your thigh for easier drilling of wall studs. Old Vintage Metal / Tin Oval Shape Lunchbox / Lunch Pail / Box depicting an Indian Theme! Item Description: Included in this auction are one Vintage Metal or Tin Lunchbox or Lunch Pail which depicts a design with an Indian hunting Buffalo Theme.

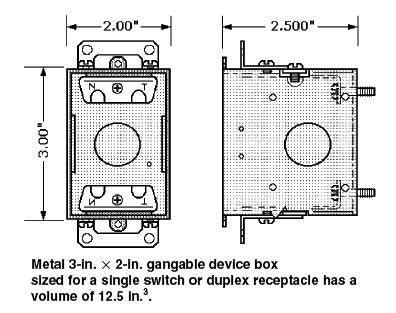

0 · rough in electrical box sizes

1 · how to rough in electrical box

$40.00

There are two simple ways to connect a ground screw to the box, a screw or a grounding clip. If there's no threaded hole for a ground screw, a clip is the . You can drill a 3/16" (or slightly smaller 11/64") pilot hole in the box and screw . Drill Holes in the Framing. Bore 3/4-inch holes through the framing members about 8 inches above the boxes. Pro tip: Center the bit on the stud, brace the drill and apply pressure with your thigh for easier drilling of wall studs.There are two simple ways to connect a ground screw to the box, a screw or a grounding clip. If there's no threaded hole for a ground screw, a clip is the easy way to go, rather than drilling and tapping the box.

You can drill a 3/16" (or slightly smaller 11/64") pilot hole in the box and screw the self-tapping ground screw into it. If the grounding screws you have are not self-tapping, then you will also need to tap the hole, but most grounding screws self-tap. The only mounting holes currently in the junction box are in the bottom of the box- there are none on its sides. It would be easy enough to simply drill a side hole(s) through the junction box through which I could then mount it to the stud.

For grounding it is important to use fine threaded machine screws such as 10/32 to attach a grounding pigtail wire to a metal electrical box or a grounding lug to a metal enclosure. You can drill and tap more #10-32 ground screw holes into the junction box, if you really want to. That is the conventional size. You can use any thread pitch -32 or finer, and any bolt size #8 or larger. There are some hole saws and stepped drill bits which can be used to drill in sheet metal. I have used them with the purpose of creating knockout whereas there was none at a particular spot. The stepped drill bits, as the one shown below, will also deburr the hole for . Can I just drill the hole in the panel or do I have to line up the knockouts? The NEC does not prohibit you from drilling holes in a panel as long as it is done in a workmanlike manner, and as long as you don't end up with openings when you are done.

I carry a few of those greenleee 10/32 drill tap bits for when I encounter an older box with no ground screw hole. I drill and tap and the same time then just use one of the screws. I know green ones are not required but I just like to use them.

rough in electrical box sizes

If you drill a hole, there's no clamp to hold the wire in place. You could drill a big hole and add a metal clamp as used on metal boxes, but then the clamp isn't grounded. You could come up with creative non metallic clamps, or ways of grounding a metal one, but anything you invent yourself isn't code legal and is more work than a new box by . Drill Holes in the Framing. Bore 3/4-inch holes through the framing members about 8 inches above the boxes. Pro tip: Center the bit on the stud, brace the drill and apply pressure with your thigh for easier drilling of wall studs.There are two simple ways to connect a ground screw to the box, a screw or a grounding clip. If there's no threaded hole for a ground screw, a clip is the easy way to go, rather than drilling and tapping the box. You can drill a 3/16" (or slightly smaller 11/64") pilot hole in the box and screw the self-tapping ground screw into it. If the grounding screws you have are not self-tapping, then you will also need to tap the hole, but most grounding screws self-tap.

The only mounting holes currently in the junction box are in the bottom of the box- there are none on its sides. It would be easy enough to simply drill a side hole(s) through the junction box through which I could then mount it to the stud.

For grounding it is important to use fine threaded machine screws such as 10/32 to attach a grounding pigtail wire to a metal electrical box or a grounding lug to a metal enclosure.

You can drill and tap more #10-32 ground screw holes into the junction box, if you really want to. That is the conventional size. You can use any thread pitch -32 or finer, and any bolt size #8 or larger.

how to rough in electrical box

There are some hole saws and stepped drill bits which can be used to drill in sheet metal. I have used them with the purpose of creating knockout whereas there was none at a particular spot. The stepped drill bits, as the one shown below, will also deburr the hole for . Can I just drill the hole in the panel or do I have to line up the knockouts? The NEC does not prohibit you from drilling holes in a panel as long as it is done in a workmanlike manner, and as long as you don't end up with openings when you are done.

I carry a few of those greenleee 10/32 drill tap bits for when I encounter an older box with no ground screw hole. I drill and tap and the same time then just use one of the screws. I know green ones are not required but I just like to use them.

can cnc machines use any software

can a junction box be in the attic

$99.00

drill ground hole electrical box|rough in electrical box sizes