how to create sheet metal parts in inventor I am trying to make a chute out of 4 pieces of sheet metal. Is there a way to take a solid lofted part, shell it, and then break off each side of the the object for cutting and welding . Mount the junction box to the wall by screwing in screws through the designated holes. Use wire strippers to strip 3⁄4 inch (19 mm) of casing insulation off the end of every wire going into the junction box. Twist the exposed ends of .

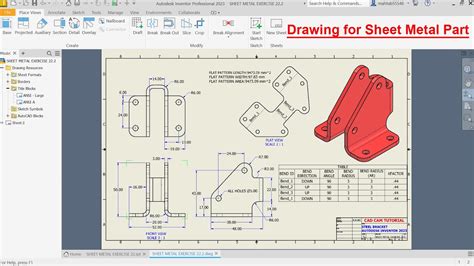

0 · sheet metal drawing in inventor

1 · inventor unfold sheet metal

2 · inventor sheet metal tutorial pdf

3 · inventor sheet metal exercises pdf

4 · inventor sheet metal defaults

5 · inventor change sheet metal thickness

6 · edit sheet metal rule inventor

7 · autodesk inventor sheet metal tutorial

$15.99

Autodesk inventor Tutorial - 3D Model 69In this Inventor tutorial, we will show you how to create sheet metal parts using Autodesk Inventor. We'll begin by e.You can create sheet metal parts in several ways. Create a sheet metal part using the sheet metal template. The template uses your settings for material thickness, bend radius, and corner .

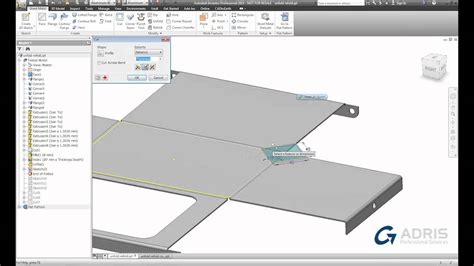

electrical box regulations

Within the Autodesk Inventor design environment, a sheet metal part can be displayed as a folded model or a flat pattern. With sheet metal commands, you can unfold features and work on a model in a flattened state, and then refold . I am trying to make a chute out of 4 pieces of sheet metal. Is there a way to take a solid lofted part, shell it, and then break off each side of the the object for cutting and welding . Autodesk® Inventor® has tools for creating sheet metal-specific features that follow a manufacturing standard, ensuring your ability to flatten your 3D model.

2018 Aug 6. In part 22 of the Autodesk Inventor 101: The Basics series, we'll take a look at how to use the basic functionality of the sheet metal environment in Autodesk Inventor, as well.

electrical box settee

Place and constrain a sheet metal part in Inventor. Place a sheet metal part into an assembly and apply constraints so that you can design within the context of an assembly. A variety of modern parts are designed and constructed using sheet metal – and chances are you’ll be designing a part out of sheet metal at some point, too. Autodesk Inventor now has integrated sheet metal tools that .Add holes to sheet metal parts in Inventor. Inventor. You can find "Make Components" within the tab "Sheet Metal" on the right. When opening the function you can select the bodies you want to make components of. Also within the first window you can select if you want to make .

electrical box sheetrock marking template

Hi! Based on your description, I think Contour Flange might be a better choice here. You need to create a sketch with a big arc. At where the two side meet, create linear segments no overlapping. Next, use sketch fillet command to round the sharp corners. Lastly, use Contour Flange to create the sheet metal part. Does it make sense? Many thanks!

Autodesk® Inventor® has tools for creating sheet metal-specific features that follow a manufacturing standard, ensuring your ability to flatten your 3D model. Learn Autodesk inventor how to use sheet metal for beginner(DONATE) Support us to buy tools and software: https://www.paypal.com/paypalme/mufasucad#inventor#. Learn autodesk inventor 2023 basic tutorial for beginner how to working with sheet metal#inventor #sheetmetal #mufasucad How to define a custom sheet metal iProperty with thickness and classify sheet metal parts according to it in Inventor? How to export this classified list to excel? Inventor can create specific custom iProperties and classify by them. Use the following steps: Define sheet metal template with custom iProperty - Thickness: Open empty sheet metal template. Open .

The following practices apply for sheet metal parts with Model States: When you create a drawing view for a sheet metal part, you can select an explicit Model State member on the Component tab of the Drawing View dialog. If a flat pattern is available in the selected model state, the Flat Pattern option is enabled in the Drawing View dialog.

You can find "Make Components" within the tab "Sheet Metal" on the right. When opening the function you can select the bodies you want to make components of. Also within the first window you can select if you want to make an assembly of it (the components will be placed and grounded like the multibody part 'skeleton').

Use Sheet Metal tools to create the part. . In your example Inventor incorrectly mapped the points for the Loft. . Please see two attached parts for two ideas on the workflow you would like to have. One is using the part loft feature then create flat pattern, the other is using sheet metal lofted flange feature, which should be the most . Is it possible to split a sheet metal part and still be able to create a flat pattern in Inventor? To split a sheet metal part in Inventor and have both half still be able to create a flat pattern, do the following. Do a Save Copy As and either give it a different name or add right or left hand to it. Keep the original file so you will have two copies. Open or use the open copy of the .

sheet metal drawing in inventor

inventor unfold sheet metal

You can create sheet metal parts in several ways. Create a sheet metal part using the sheet metal template. The template uses your settings for material thickness, bend radius, and corner relief. You use sketch commands to create a profile for a base face or an initial contour flange. Then you exit the sketch and create your sheet metal feature . This is an assembly of 4 parts. Must thicken each part individually in it's own file. Since these are planar parts with no bends they could actually be thickened as multibody solids and then push out the parts. The instructions were intended to also cover more complex cases where there are bends (multi-body does not support sheet metal bends).

weld within a part (or sheet metal part). As previously stated: - open a new/empty weldment.iam file - place your sheet metal file - place the welds required to close your corners - save the weldment.iam - make a drawing of the weldment showing the beads with callouts - create any flat pattern drawings from the original sheet metal file-- Gary .

inventor sheet metal tutorial pdf

I wrote a Macro for inventor that flat patterns all sheetmetal parts and exports them to dxf and dwg. . So if you have a model that contains sheet metal and normal parts, this will just send out the . 2020 New version for APP for Sheet metal templeates fo make a 3D solid Sheet metal & Automate CUSTOM iProperties for Autodesk Inventor. Now . The overall goal is to take 2 parts and make them into a sheet metal part. I converted one part into a sheet metal one and then copied the sketch from the other part. Sketch 6 is the other part and I pasted it into the sheet metal part. I want to make a face out of this sketch and then fold the part along a construction line. The challenge is the compound bending on the part, which makes it impossible to create in Inventor sheetmetal which relies on planar faces to unfold. In Rhino you can use various method of flattening a complex surface.

Hello, I am trying to define an A-Side for my sheet metal part using VBA and it fails Dim oPartDoc As PartDocument Set oPartDoc = ThisApplication.ActiveDocument Dim oDef As PartComponentDefinition Set .

How to create a Punch Tool in the Inventor Sheet Metal environment to reuse it in different Sheet Metal Parts? Follow the instructions below: YT: Custom Punch Tool Sheet Metal YT: How to Create Open Face Embossed Punch Features ArticleId:kA93g0000000HBZ ArticleNumber:000283097 A look into creating drawings of Inventor sheetmetal components and flatpatterns

Check out more tips and articles here www.ketiv.com/blog/In this week's video, Jonathan Landeros of KETIV Technologies shows how you can create a sheet metal. This video goes over how you are able to convert 3D solids to sheet metal parts in Autodesk Inventor.Related Blog Posts https://www.hagerman.com/the-hub/inve. Will this work? I just made corner seams with a width of .001" then added the bend. I hade to delete the faces on the edge and have them heal on the 2 parts that are parallel. Also make sure all the sheet metal thickness is the same from one file to the next or things won't work right. Hope this is what you want.

*This is a feature only available in 2017 with the R3 update. This is an advanced guide on how to create text profiles in sheet metal which can be included i.

Inventor 2018 file is attached. Solved: Hello everyone. I need help. I have the detail which was created as a simple, then i converted it to the sheet metal detail in order to get . set your sheet metal style to match the parts material thickness and then press the Create Flat Pattern button . click on the Contour Flange icon in the Create . Recently a customer reached out to Pete and was having difficulty forming flanges at specific angles that were difficult to calculate. In this video Pete wi. Understanding Bend Allowance and Bend Deduction in Inventor; Calculating Bend Allowance and Setback Example; How to check a K-factor of sheet metal part in Inventor; Determining correct K factor within sheet metal environment of Inventor; Flat Patter of Sheet Metal Part changed size after KFactor were changed in Inventor

Learn how to use Autodesk Inventor's sheet metal contour flange feature in this quick tip video. In our software (SigmaNEST), we are able to create a sketch on the Inventor part file (if sheet metal, the sketch has to be in the Flat Pattern), and give it a particular name. Then in the nesting software, we set it to look for that sketch name for the Marking process, similar to how layers would be used in an AutoCAD-based pattern.

electrical box recessed lighting

electrical box regulations united states

Wall-mounted enclosures house and protect industrial electrical/electronic components, instruments and devices. Metallic or non-metallic enclosures are available in various NEMA ratings to fit many environmental protection requirements.

how to create sheet metal parts in inventor|inventor change sheet metal thickness