sheet metal extruded tapped holes Mate leads the punching industry with a tool system designed to produce threaded holes in previously punched or extruded holes, in all types of sheet metal. Called EasyTap™, this . Steel wool is a fantastic material for cleaning wood furniture and cupboards if you thoroughly understand how to use steel wool on wood. It will quickly remove even the toughest stains. You’ll have a lovely piece of furniture that’s easy to clean and care for with a little elbow grease!

0 · thread tapping system

1 · thread tapping machine

2 · tapping tools for metal

3 · tapping tool for sheet metal

4 · tapping threads for sheet metal

5 · tapping sheet metal

6 · metal hole punching tool

7 · extruded hole punching tools

A roof color visualizer is a free software program that Western States Metal Roofing offers where you can upload a photo of your home and digitally try out different metal panels and colors on your roof (and siding) to get the best idea of how each combination will look.Looking for a welder for sheet metal? We found 5 best welders for doing it that don't cost a fortune - check them out in our article.

UniPunch tooling can be used to simultaneously punch a hole and extrude the material down. Applications include for self-tapping sheet metal screws or, in .Mate leads the punching industry with a tool system designed to produce threaded holes in previously punched or extruded holes, in all types of sheet metal. Called EasyTap™, this .

Tapping in sheet metal is the use of a tapping tool to form material in a pre-punched or extruded thru hole, to create threads for engagement of a non-self-tapping screw. . The inside diameter of an extrusion may serve as a bearing surface, a pivot point or an interface for a press-fit with another component. Most often, hole extrusions find use as screw attachments, usually cut or formed with .

Fix the workpiece securely to prevent it from moving. Choose the correct size drill and drill the hole. Select the right tap for your material and thread size. Place the tap into a tap wrench and .This article provides Tap-Fix ® hole size recommendations for metals using light gauge punched/extruded materials. The following illustration shows the extruded hole geometry.

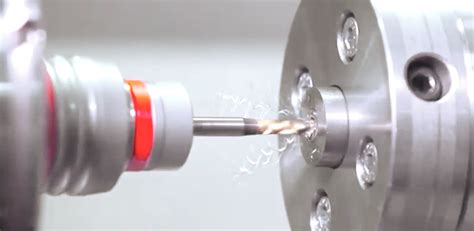

A new tooling system produces threaded holes in all types of sheet metal, eliminating the need for secondary tapping operations or additional fasteners. This is sort of a design question, but I need to make threaded punched holes in sheet metal, something like this. I am unsure about how the process of making this. Would I need a guide hole before punching and what .

For instance, if I use the hole wizard to make a hole for a 1/4-20 tap (tapped hole), and then use the thread wizard to add a 1/4-20 thread to that hole (extruded), the hole comes out way too small (perhaps 0.15). In Fusion, .

How Are Tapped Holes Shown on Drawings? Tapped holes are shown on drawings as follows: The “2.5” is the pitch of the thread, which is the distance in millimeters between each thread. For a UNF thread, a through 1½” 12 hole would look like this: The ’12’ means that there are 12 threads per inch. What Are Tapped Holes Used For? Tapped .Extrusions our commonly used to accept sheet metal screws or permit tapping into a deeper distance than just the material thickness. A pre-punched hole is required as a one hit pierce and extrude gives poor hole quality, and has limited adjustment on the machine. . The diameter of the pre-punched hole ultimately determines the height of the . There is a specific type of threaded hole that I've seen on sheet metal, and my metal shop tells me its called an extruded hole. . An Extruded Hole feature is in the Design Library > forming tools > embosses section. . I can create them on standard tapped holes, but not on the 3M hole above that I formed. Excuse the noob questions. Thanks,The minimum hole-to-edge distance is measured from the edge of the tapped hole to the nearest cut feature, and the specification can be found on each individual material info page by stock thickness. Below is a chart of SendCutSend’s available tap sizes. Each tap size is paired with the required through-hole size that will be needed in your .

In Machine Tapping: Tapping tools allow you to tap holes right in the punch press with unparalleled speed and accuracy. Perforating (Clusters): Make more holes with every stroke of your machine. Clusters can be made to punch 2-120+ holes at a time. Parting: Minimize down time with your parting tool.

metal mitre box for aluminium and pvc trim

thread tapping system

With the punched hole properly prepared, it’s ready to be extruded. Whenever possible, extrude the hole in the direction opposite of punching. This subjects the sheared edge—less damaged by cutting than the fracture zone—to the most deformation. Most extrusions are used to produce tapped or threaded hole features. Tapping Minimums and Maximums. You’ll notice on our Processing Min/Max sheet that the minimum part size for tapping doesn’t change depending on the material and its thickness, unlike with our other processes. This is because tapping isn’t limited by the overall part size, and the only thing that changes depending on the material and its thickness is the .

Pilot Hole Sizes for Steel Sheet Metal . ANSI Hardware Design and Application Guide ISO Metric Hardware Engineering and Design Data Fastener and Screw / Bolt Design, Formula & Calculations. Approximate Pilot Hole Sizes for Type A Steel Sheet Metal Thread Forming Screws. . Extruded. Drilled or Extrusions. Extruded holes are formed up or down to create a formed collar on one side of the material (Figure 9).Commonly tapped as well (also on the punch press), extruded holes are used with thread cutting screws or other fasteners, or they are used as locators for other press-fit applications. Threaded holes are produced in pre-punched holes or in extruded holes located on sheet. Features include automatic lubrication system, pre-pierce hole miss protection, and push button length adjustment. Tooling produces full range of threaded hole diameters in materials including stainless steel, mild steel, and aluminum.

power than extruded/tapped or stamped threads. They are used chiefly where good pullout and torque loads are required in sheet metal that is too thin to provide secure fastening by any other method. Even if the sheet is thick enough to sustain tapping, it may actually be more economical to use self-clinching fasteners with gaugeable threads.

Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends. Bends in .THE SOURCE OF SAVINGS FOR YOUR FASTENING POINTS FASTENING POINT Fastening points, thanks to the processing of sheet metal, can be produced in many different ways. . Examples of extruded tapped holes with technical specifications: Extruding the metal for the tapped hole provides mechanical and economical advantages in comparison to other . How does a flat metal sheet transform into complex shapes and structures? This blog post delves into the intricate processes of sheet metal forming, including partial shearing, bridge drawing, and hole extrusion. .

Part II, which will appear in the September/October 2018 issue, will discuss how to reduce edge fracture in hole extrusion or collar forming. Hole extrusion, or collar forming, is widely used in stamping (see Figure 1). In this process, the blanked hole with a small diameter is extruded to a collar with a larger diameter.Burred/extruded holes can be tapped in thinner materials to allow for more threads, giving more strength in the fixing application. It can be used on a variety of material thicknesses. . AMADA is a worldwide leading manufacturer of sheet metal machinery Known by its comprehensive range of sheet metal machinery, AMADA has the solution to suit .

> How do you guys make extruded tapped holes in sheetmetal parts? Do you use the drawn > cutout command? > > Steve > Steven Sheldon > MaxVision Corporation. Yep, but it doesn't carry any detail into the Flat Pattern. Rick.

guidelines for sheet metal burring holes. Last week we shared design guidelines for the hemming process. Continuing our focus on sheet metal, this week we will cover important design guidelines for burring holes or extruded holes feature. In the burring process, holes are pierced through to make them larger, allowing the material https://www.youtube.com/channel/UCjd_zIvYtQymk0dPx3vTJcA/joinYou Can Support our Channel for more tutorials.we will learn sketch,sheet .

thread tapping machine

The metallic sheet is formed with an extruded tapped hole surrounded by an arcuate portion in the metallic sheet and a sleeve integrally with and depending from the arcuate portion. The sleeve has internal threads. . Means for uniting sheet-metal parts. US3512446A (en) * 1968-10-07: 1970-05-19: Hi Shear Corp: Countersink fasteners US4815907A .DFMPro for Sheet Metal Design Guidelines. DFMPro provides pre-configured design guidelines DFM rules for design which helps to develop better quality parts at reduced cost. Some of the common sheet metal design guidelines included are minimum distance between holes, cutouts, slots, distance between holes, cutouts, slots to part edge and bends, multiple bends in same . Spiral groove tap (SFT) The spiral flute tap has advantages when tapping in a blind hole and cutting continuously discharged steel material.This is because the right-hand spiral flute, with a cutting angle of approximately 35 degrees, allows for efficient discharge from the hole, leading to a tapping speed that can be 30% to 50% faster than that of a straight flute tap.

A thread-forming tapping tool installed on a CNC turret press allows this sheet metal fabricator to eschew tapping as a secondary operation. Some 400,000 holes later and the return-on-investment story is solid. . at a piece-part volume of 12,000 parts/yr. Each part, a face panel for electronic enclosures, requires six tapped holes. The shop .The minimum center to center distance between two holes in sheet metal parts avoids metal distortion, deformation, and fracturing. Recommended Center distance between holes in Sheet Metal Part. . Creating an extruded hole using a punching process requires extreme pressure/Force. Extruded holes very close to the part edge can lead to sheet .

metal mounting bracket for extra long jumbo housings wmb20-zm

When it comes to sourcing sheet metal for car repair, it’s important to choose the right material that matches the original specifications of your vehicle. Common options include steel, aluminum, and galvanized steel, each with its own advantages in terms of strength and corrosion resistance.If you have a set of calipers you can measure the thickness of the existing metal and then order what you need. Here's some of the common gauges and corresponding thickness of sheet steel: GA. Thickness.

sheet metal extruded tapped holes|thread tapping machine