applied sheet metal Approved Sheet metal (ASM) is an American sheet metal fabricator of custom precision prototype and low volume production sheet metal fabricated parts. When it comes to sheet metal fab, precision is key. At ASM, we offer custom . 6 Methods of Sheet Metal Welding. Now, let’s take a comprehensive look at some methods for melding metal sheets. 1. MIG Welding. Metal Inert Gas welding (MIG), also known as Gas Metal Arc Welding. It involves feeding a continuous solid wire electrode into the weld puddle with a welding gun.

0 · Tri

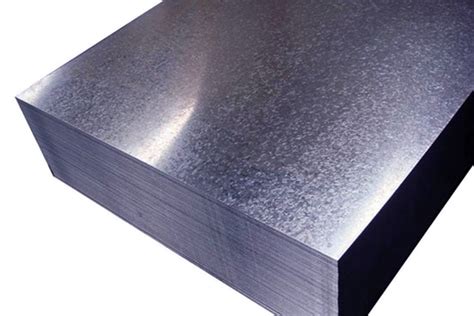

1 · The Most Common Sheet Metal Fastening Methods

2 · Guide to Galvanized Sheet Metal: Types, Uses & Selection

3 · Custom Sheet Metal Fabrication

4 · Applied Sheetmetal & Engineering

5 · 3 Classes of Sheet Metal Finishes (Updated for 2024)

West Lincoln Sheet Metal Inc - Smithville - phone number, website & address - ON - Heating Contractors, Furnaces, Air Conditioning Contractors, Sheet Metal Work.

We have over 40 years of experience in the sheet metal fabrication industry and our customers benefit from our knowledge. Our customers are provided with a superior and reliable service and our quality of workmanship is guaranteed. Approved Sheet Metal can assist in determining the right finish based on the end use application of the part. By understanding whether the .

Sheet Metal Workers make, install, and maintain heating, ventilation, and air-conditioning duct systems. . Coursework completed for the Sheet Metal Service Certificate of Proficiency may .Approved Sheet metal (ASM) is an American sheet metal fabricator of custom precision prototype and low volume production sheet metal fabricated parts. When it comes to sheet metal fab, precision is key. At ASM, we offer custom .

Additionally, this method is commonly applied for steel sheets or panels that will undergo further processing or painting. Pros and Cons of Galvanized Sheet Metal. Every material has its strengths and limitations. Here is an analysis of the pros and cons of galvanized sheet metal. . Sheet Metal Prototyping Services at Runsom.We have over 40 years of experience in the sheet metal fabrication industry and our customers benefit from our knowledge. Our customers are provided with a superior and reliable service and our quality of workmanship is guaranteed.

Approved Sheet Metal can assist in determining the right finish based on the end use application of the part. By understanding whether the part will be seen or touched, if it will be painted or powder coated, or if it will be used for showcasing purposes, they can recommend the appropriate finish.Sheet Metal Workers make, install, and maintain heating, ventilation, and air-conditioning duct systems. . Coursework completed for the Sheet Metal Service Certificate of Proficiency may be applied toward the Associate of Applied Science degree. How to reach us. Shannon Auber, Program Manager 216-987-3197 [email protected].

In this article, we’ll discuss the most common sheet metal fastening techniques and how to get the most out of your design projects, covering: The Most Common Sheet Metal Fastening Methods; Key Considerations for Sheet Metal Application; Why Choose Self Clinching Solutions for Sheet Metal? The Most Common Sheet Metal Fastening Methods

Approved Sheet metal (ASM) is an American sheet metal fabricator of custom precision prototype and low volume production sheet metal fabricated parts. When it comes to sheet metal fab, precision is key. At ASM, we offer custom metal fabrication services to meet the exact specifications of your 3D Model and/or print. Strengthening sheet metal is about choosing the right materials, balancing bend radius for structural rigidity, and employing techniques like press brakes for precise bending angles. We’ll explore practical sheet metal design tips to maximize strength and functionality.Our applied metal surfaces use real semi-precious metals that we apply and hand polish in our factory. Applied metal surfaces are suitable for interior and exterior applications. Our range of metals include zinc, copper, brass, bronze, aluminium, nickel, iron, pewter, anthra zinc, gold nickel, silver nickel, rose alloy, armoury brass, sentinel . Sheet metal is widely used due to its formability, ductility, and tensile nature. Manufacturers thus have a central goal: manipulating malleable metals accordingly while preserving structural integrity. Manipulation is achieved in multiple ways and .

Structured sheet is thin sheet metal with a 3-D structure. The 3-D structure enhances the mechanical properties of components, primarily by increasing bending stiffness because of increased inertia (the higher the structure, the stiffer the sheet).

craftsman 5-drawer steel rolling tool cabinet

Tri

Additionally, this method is commonly applied for steel sheets or panels that will undergo further processing or painting. Pros and Cons of Galvanized Sheet Metal. Every material has its strengths and limitations. Here is an analysis of the pros and cons of galvanized sheet metal. . Sheet Metal Prototyping Services at Runsom.We have over 40 years of experience in the sheet metal fabrication industry and our customers benefit from our knowledge. Our customers are provided with a superior and reliable service and our quality of workmanship is guaranteed.

Approved Sheet Metal can assist in determining the right finish based on the end use application of the part. By understanding whether the part will be seen or touched, if it will be painted or powder coated, or if it will be used for showcasing purposes, they can recommend the appropriate finish.Sheet Metal Workers make, install, and maintain heating, ventilation, and air-conditioning duct systems. . Coursework completed for the Sheet Metal Service Certificate of Proficiency may be applied toward the Associate of Applied Science degree. How to reach us. Shannon Auber, Program Manager 216-987-3197 [email protected] this article, we’ll discuss the most common sheet metal fastening techniques and how to get the most out of your design projects, covering: The Most Common Sheet Metal Fastening Methods; Key Considerations for Sheet Metal Application; Why Choose Self Clinching Solutions for Sheet Metal? The Most Common Sheet Metal Fastening Methods

Approved Sheet metal (ASM) is an American sheet metal fabricator of custom precision prototype and low volume production sheet metal fabricated parts. When it comes to sheet metal fab, precision is key. At ASM, we offer custom metal fabrication services to meet the exact specifications of your 3D Model and/or print.

Strengthening sheet metal is about choosing the right materials, balancing bend radius for structural rigidity, and employing techniques like press brakes for precise bending angles. We’ll explore practical sheet metal design tips to maximize strength and functionality.Our applied metal surfaces use real semi-precious metals that we apply and hand polish in our factory. Applied metal surfaces are suitable for interior and exterior applications. Our range of metals include zinc, copper, brass, bronze, aluminium, nickel, iron, pewter, anthra zinc, gold nickel, silver nickel, rose alloy, armoury brass, sentinel . Sheet metal is widely used due to its formability, ductility, and tensile nature. Manufacturers thus have a central goal: manipulating malleable metals accordingly while preserving structural integrity. Manipulation is achieved in multiple ways and .

The Most Common Sheet Metal Fastening Methods

cpc junction box

In this guide, we will take you through a detailed process on how to weld titanium. From properties that makes welding titanium possible, detailed procedures, precautions to tips – by the end of this guide, you should be able to complete the process easily. Let’s dive right in: Why Weld Titanium?

applied sheet metal|The Most Common Sheet Metal Fastening Methods