how to operate cnc milling machine In short, being proficient in operating a CNC milling machine is not something that can be achieved overnight. It requires accumulated . See more Find Steel angles, brackets & braces at Lowe's today. Shop angles, brackets & braces and a variety of hardware products online at Lowes.com.

0 · types of cnc milling operations

1 · operations performed on milling machine

2 · milling advantages and disadvantages

3 · introduction to cnc milling machine

4 · different types of milling operations

5 · cnc milling for beginners

6 · cnc horizontal milling for dummies

7 · basic milling machine operations

I did see one massive Okuma bridge mill in the factory, but the vast majority of Doosan machines are made on other Doosan machines. My tour was conducted by Dongil .

Step 1. Turn back to the reference point Step 2. Move the machine table to the middle of the machine (press the negative key, otherwise it will overtravel), and place the workpiece on the table. Step 3. Use a dial indicator to align, and then clamp the workpiece (if the workpiece permits, it can be milled after . See more⇲ The operator should be familiar with the composition, structure and use environment of the CNC milling machine used, and strictly operate in accordance with the requirements of the operating manual of the machine tool, and try to avoid failures caused . See moreIn short, being proficient in operating a CNC milling machine is not something that can be achieved overnight. It requires accumulated . See more In this CNC milling machine tutorial, we will provide a comprehensive guide on how to use a CNC milling machine.

November 15, 2024. In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials. Unlike manual milling, where an operator’s steady . In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.This guide aims to simplify the process by providing clear instructions and practical tips for operating a CNC machine effectively. Following this guide will give you confidence in utilizing these powerful tools for your manufacturing . With this page, we’re going to bring together links to articles that cover all the basics you’ll need to use a CNC machine or to get started with the planning to buy or make a CNC machine. If you go through these articles, .

we have books with tips and tricks, tutorials, and design for cnc: https://www.makershed.com/products/make-cnc-epack-pdfs. The CNC machine operates based on instructions encoded in a numerical control (NC) program, typically written in a language called G-code. This program specifies the tool’s .CNC machines have revolutionized the manufacturing industry, providing unparalleled precision and efficiency in milling and drilling operations. In this comprehensive guide, we will delve into the world of CNC machines, exploring .Step 1: Choose Your Workspace. Find a suitable location for your CNC machine. Ensure you have enough space to move around comfortably and access power outlets. Consider .

types of cnc milling operations

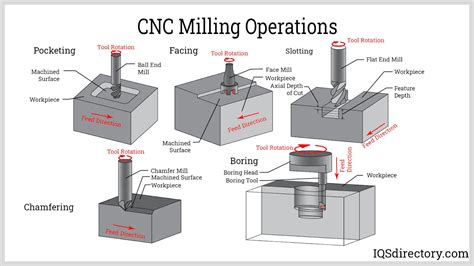

Face Milling: This operation involves cutting flat surfaces perpendicular to the axis of rotation. It is commonly used to create smooth finishes on large surfaces or to remove material quickly.; Peripheral Milling: In this operation, the cutter moves .

How to operate it. The CNC milling machine requires the management of computer numerically controlled equipment. The equipment has to be set up for operation as it produces parts and tools from different .Here are the 3 most popular types of CNC milling machines: 3-axis milling machine: The 3-axis milling machine has a vertical spindle and a horizontal spindle. 4-axis milling machine: Overall, the 4-axis milling machine is similar to .

The video was recorded to train beginners on how to operate the CNC milling machine with Fanuc OiMd controller. CNC milling machines automate the production process, reducing the need for human intervention and thereby reducing errors. These machines can operate continuously over extended periods to increase productivity. CNC milling machines are the top-end option because they provide a high-precision solution to parts manufacturers. These machines are . The first step in machining is deciding which approach to take and which machine to use. There are six general styles of machining that are most commonly used. Mill. The most common kind of CNC machine and the type that is most often used. Milling involves sending a rotary cutting tool into the material to cut away material along three linear axes. CNC BARON MILLING MACHINE; Jr. CNC Benchtop Milling Machine; Lathe 1440 CNC Machine Turning Center Catalog; CNC Milling Machines. Table Top Milling Machines At CNC Masters, we offer a range of outstanding table top milling machines. Each of these compact CNC mills is designed to pack maximum power into a small footprint, all while remaining .

operations performed on milling machine

The saddle and knee are hand driven for vertical and cross feed adjustment while the worktable can be either hand or power driven at the operator's choice. Basic milling machine configurations are shown in Figure 8-1. SAFETY RULES FOR MILLING MACHINES . Milling machines require special safety precautions while being used.

Learn how to operate CNC machine and elevate your skills! Gain expert insights on the process to control and manage these advanced tools efficiently. Home; About; Services. CNC Milling; . The condition of the tools used in CNC machining, such as the end mill or the bits, can significantly impact the final product’s quality. . A computer numerical control (CNC) mill is capable of cutting and drilling many different types of material including steel, aluminum, wood and plastic. An CNC mill operator is in charge of making sure that the parts coming out are well within the .

piezas de barril de cilindro de mecanizado cnc oem

The operator salary of CNC milling machines can range from to per hour. Therefore, the total cost of CNC services, in this case, would be around per hour. Higher quality and more sophisticated CNC machines cost more. For example, an hourly rate of 0 is standard for 5-axis CNC machining. Watch Next - 3D Printer Basics: https://youtu.be/RgECxaxUIb0CNC Routers for Hobbyists can be intimidating! In this video, I'll cover all the CNC basics that .

CNC BARON MILLING MACHINE; Jr. CNC Benchtop Milling Machine; Lathe 1440 CNC Machine Turning Center Catalog; CNC Milling Machines. Table Top Milling Machines At CNC Masters, we offer a range of outstanding table top milling machines. Each of these compact CNC mills is designed to pack maximum power into a small footprint, all while remaining .Regular maintenance: This is crucial for keeping your CNC machine operating at its best. Here are some essential maintenance procedures you should perform: Cleaning: Regularly clean all surfaces of your CNC machine, including the work area, tooling, and control panel. Use appropriate cleaning agents and tools to remove any debris or coolant residue. They also read blueprints to create a code the CNC machine can understand, known as G-code. G-code is what directs the machine's tools to create a specific product. CNC machines are commonly used by trained .

A CNC milling machine and manual milling machines are both useful pieces of equipment, but they require different areas of expertise. CNC machining requires the operator to design the finished part, program the correct tool path for the . Read more to know how to operate a CNC machine and improve your DIY skills! . For the tool sensor method, place the tool sensor on top of the part to be cut in. Bring the tip of the mill bit down to 8-10mm above the sensor .Axis: Refers to the directions in which the CNC machine can move. Most common CNC machines are three-axis (X, Y, and Z), which represent horizontal, vertical, and depth movements. Controller: The computer or device that interprets the G-code and sends commands to the CNC machine. WCS (Work Coordinate System): A system used to define the .

milling advantages and disadvantages

A Roger b CNC Mill tutorial Video 908 How to operate a CNC milling machine and Mach3 Thank you for watching I need your help to keep making good contentPl. CNC milling machines are programmed using the X, Y, and Z axes, providing precise control over the tool’s movement in three dimensions. With their versatility, CNC milling machines find extensive use in various industries, including automotive, aerospace, and mold making. Both CNC lathes and CNC milling machines rely on CNC programming .

CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on the spindle will shape the materials vertically, and the cutters move while the workpiece remains stationary, the machines can cut into the part easily.Thank you for purchasing the software CNC Operator for the Sysmac NJ/NY-series NC integrated con-troller (hereinafter referred to as CNC Controller). The CNC Operator software enables your PC or IPC to be used as the operator console of the CNC Controller. This manual describes how to operate CNC Operator when primarily using the CNC Controller. To use a milling machine, one must first understand its basic components and functions. The machine consists of a cutting tool, known as a milling cutter, that rotates at high speeds and removes material from the workpiece. . CNC milling machines can be programmed to create parts with a high degree of accuracy, making them ideal for . Modern High Speed CNC Milling Machine Working.XK7124 original design by WMTCNCWorking table: 800x240mmX/Y/Z axis travel: 425/245/530mmSpindle taper: BT30Spin.

introduction to cnc milling machine

different types of milling operations

Below is the diagram of a milling machine with a rotary table: How to Use a Rotary Table on a Milling Machine? You can use a rotary table milling machine to perform precision curved cuts and positioned cuts on round stock, as well as drill holes accurately. Let’s take the drilling operation as an example, to see how to use a rotary table on a . CNC Milling Machines utilize Computer Numerical Control (CNC) to automate the machining process with high precision. CNC mills can be vertical or horizontal and are often used for complex 3D shapes. They range from smaller machines for prototyping to large-scale production units that require minimal operator intervention.

we have books with tips and tricks, tutorials, and design for cnc: https://www.makershed.com/products/make-cnc-epack-pdfs

cnc milling for beginners

Therefore, all conduits installed below the hazardous locations of a motor fuel dispensing facility are required to be sealed within 10 feet of the point of emergence from below grade.

how to operate cnc milling machine|operations performed on milling machine